Sterilization device for textile processing

A disinfection device and textile technology, applied in the textile field, can solve the problems of no humidity sensor, odor elimination, and inability to detect the humidity of the disinfection cabinet body, so as to achieve the effect of ensuring a normal disinfection environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

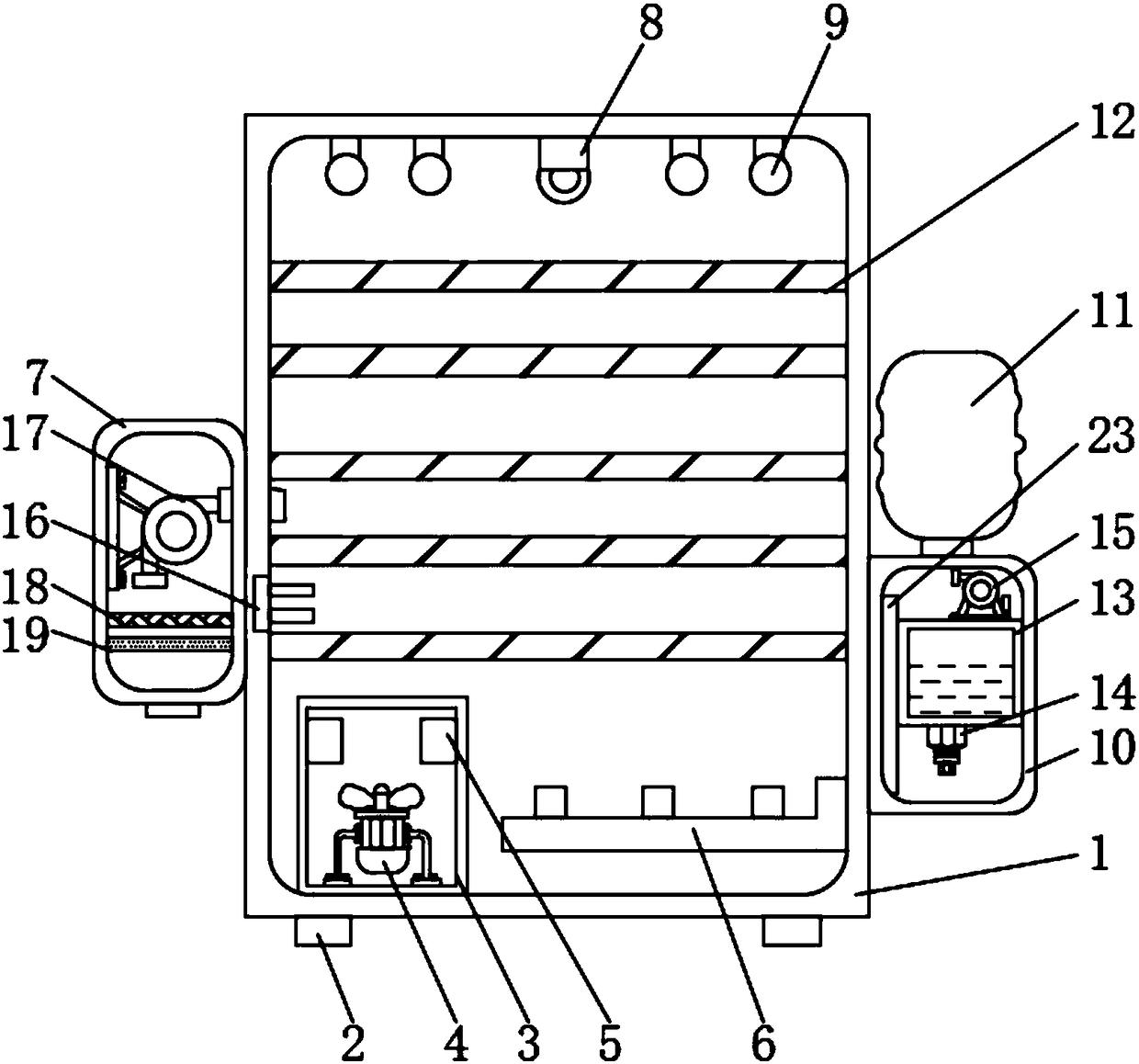

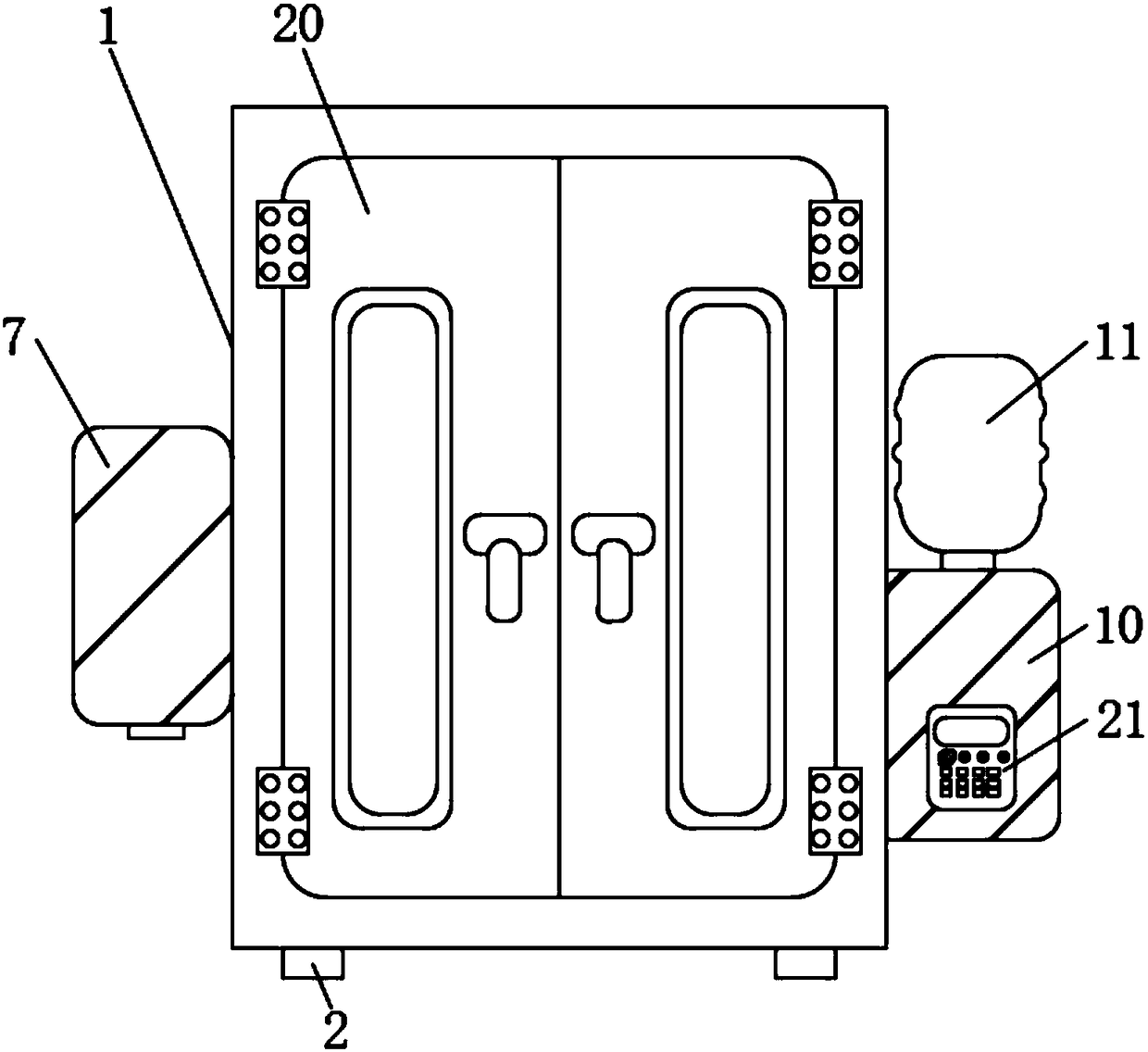

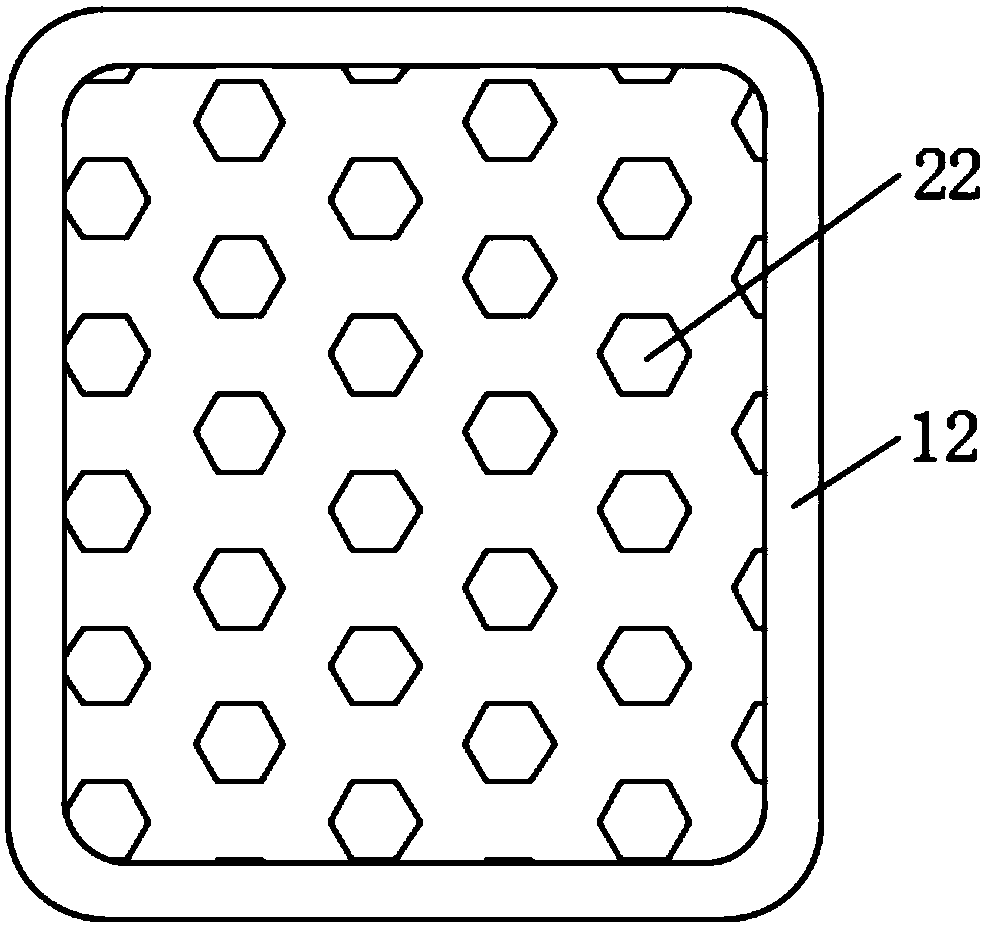

[0021] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a disinfection device for textile processing, comprising a disinfection cabinet body 1, the lower end of the disinfection cabinet body 1 is provided with a support 2, and the inner bottom of the disinfection cabinet body 1 is provided with Heating chamber 3, the inside of the disinfection cabinet body 1 is provided with a shelf 12 close to the upper position of the heating chamber 3, and the inner lower position of the disinfection cabinet body 1 is provided with a second nozzle 6 near the side of the heating chamber 3 for disinfection. The inner top of the cabinet body 1 is provided with a lighting lamp 8, and the side of the inner top of the disinfection cabinet body 1 near the lighting lamp 8 is provided with an ultraviolet disinfection lamp 9, and one side of the disinfection cabinet body 1 is provided with a clean room 7, and the disinfection cabinet body The other side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com