Motor waterproof end cover glue injection machine

An end cap and glue injection technology, which is applied in the field of glue injection machines, can solve problems such as reduced efficiency, cracked sealing rings, and long time consumption, and achieve the effects of improving work efficiency, convenient placement, and improving product production efficiency and matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

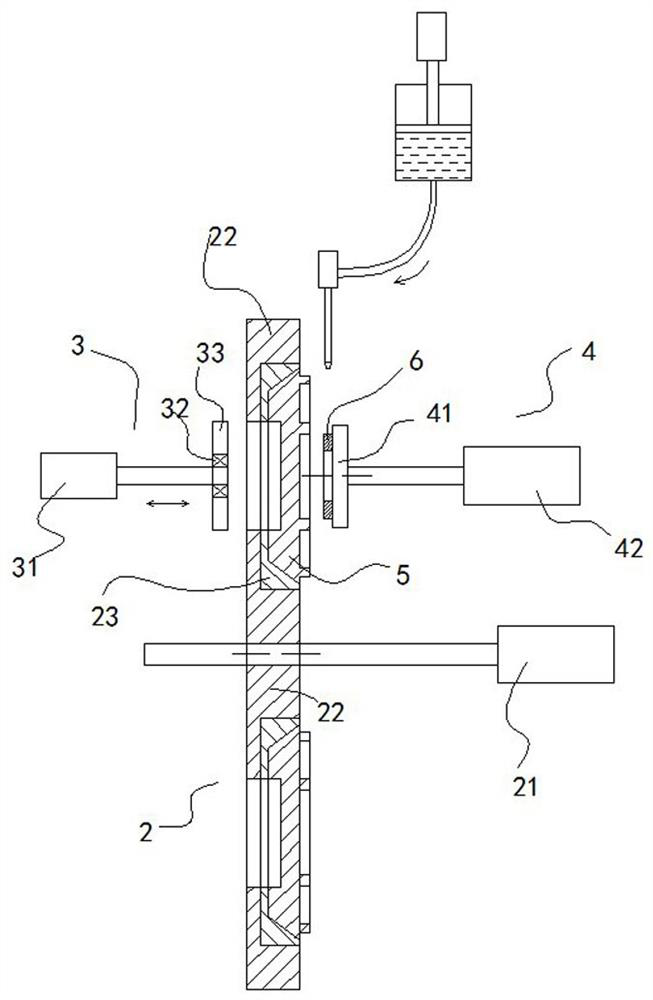

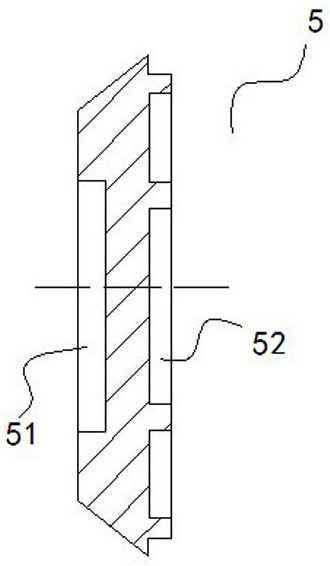

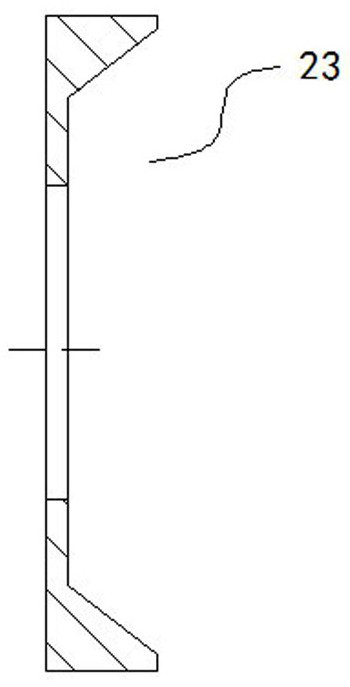

[0015] Please refer to Figure 1 to Figure 5 , the motor waterproof end cap glue injection machine in the figure includes a glue injection mechanism 1, an end cap rotating platform 2, an end cap pushing mechanism 3, and an oil seal placement rotating mechanism 4. The research and development of the motor waterproof end cover glue injection machine is mainly to facilitate automatic operation, reduce the use of labor, and improve the accuracy and performance of the product. The glue injection mechanism 1 is used for the glue injection operation where the end cap 5 needs glue injection. The end cap rotating platform 2 is used to place a plurality of end caps 5 and rotate according to a certain frequency, so that every time the mating of one end cap 5 is completed, the mating of the next end cap 5 can be prepared. The end cover push-out mechanism 3 is used to push the end cover 5 from the end cover fixing seat 23 to the oil seal fixing seat 41 to cooperate with the oil seal 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com