Control method for hot rolled low carbon steel uncoiling cross creases

A control method and horizontal folding technology, which is applied in the field of metallurgy, can solve the problems of low surface quality of hot-rolled low-carbon steel sheets, and achieve the effects of prolonging service life, improving production efficiency and product qualification rate, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

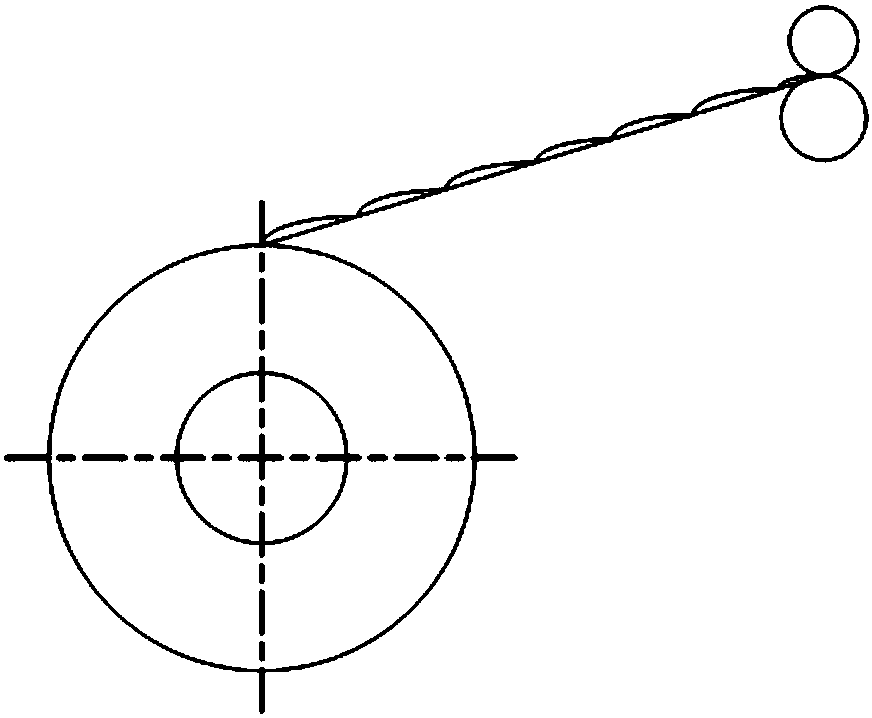

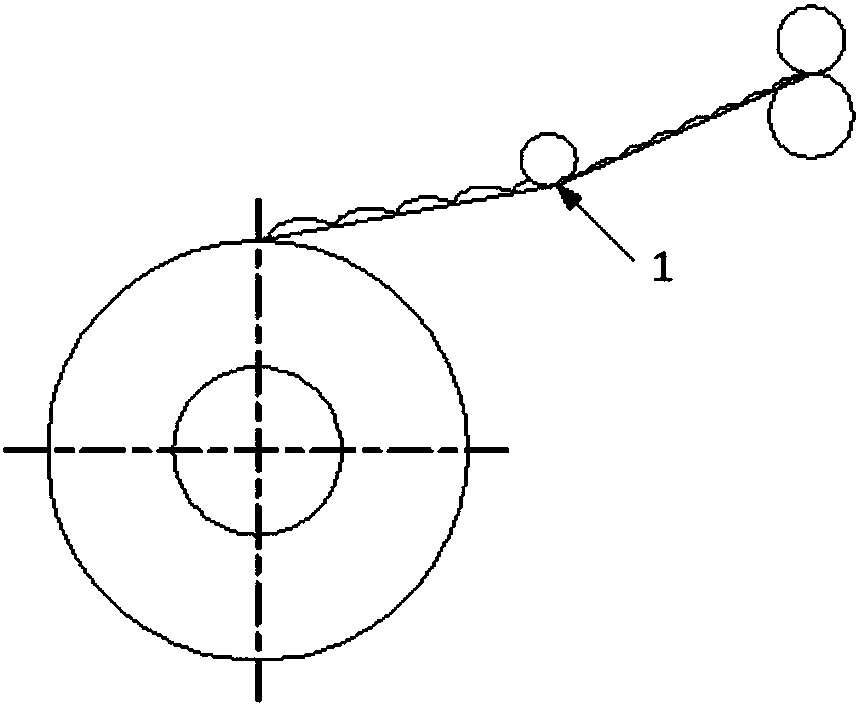

[0033] A method for controlling cross-folding of hot-rolled low-carbon steel uncoiling, comprising the following steps;

[0034] Step 1. Real-time detection of the diameter of the hot-rolled low-carbon steel coil to be uncoiled;

[0035] Step 2, the diameter of the hot-rolled low-carbon steel coil that measures according to step 1 adopts following formula to calculate the reduction of deep bending roll:

[0036] Deep bending roll reduction = 4250+275-535.2*ln(Diam)-m*(Diam-n)^2

[0037] In the formula, ln represents the logarithm;

[0038] Diam represents the diameter of the current hot-rolled low-carbon steel coil;

[0039] m is 0.00009;

[0040] n is 1300;

[0041] Step 3, pressing down the deep bending roll according to the reduction value of the deep bending roll calculated in step 2, and uncoiling the hot-rolled low carbon steel coil;

[0042] Utilize above-mentioned formula, carry out programming in PLC, realize the real-time detection of the diameter of above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com