Guardrail bending device

A bending device and guardrail technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult control of the bending angle, easy to break, etc., to save manpower, avoid excessive rigidity, and improve the effect of forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

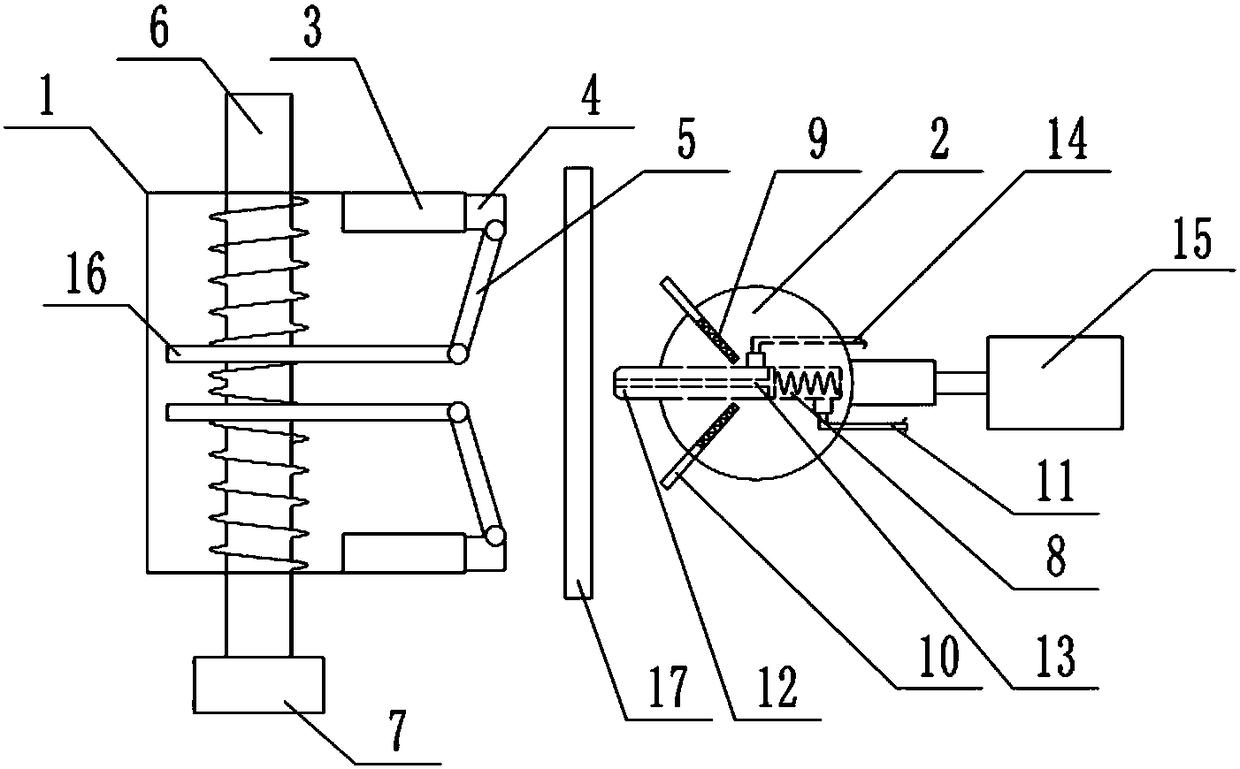

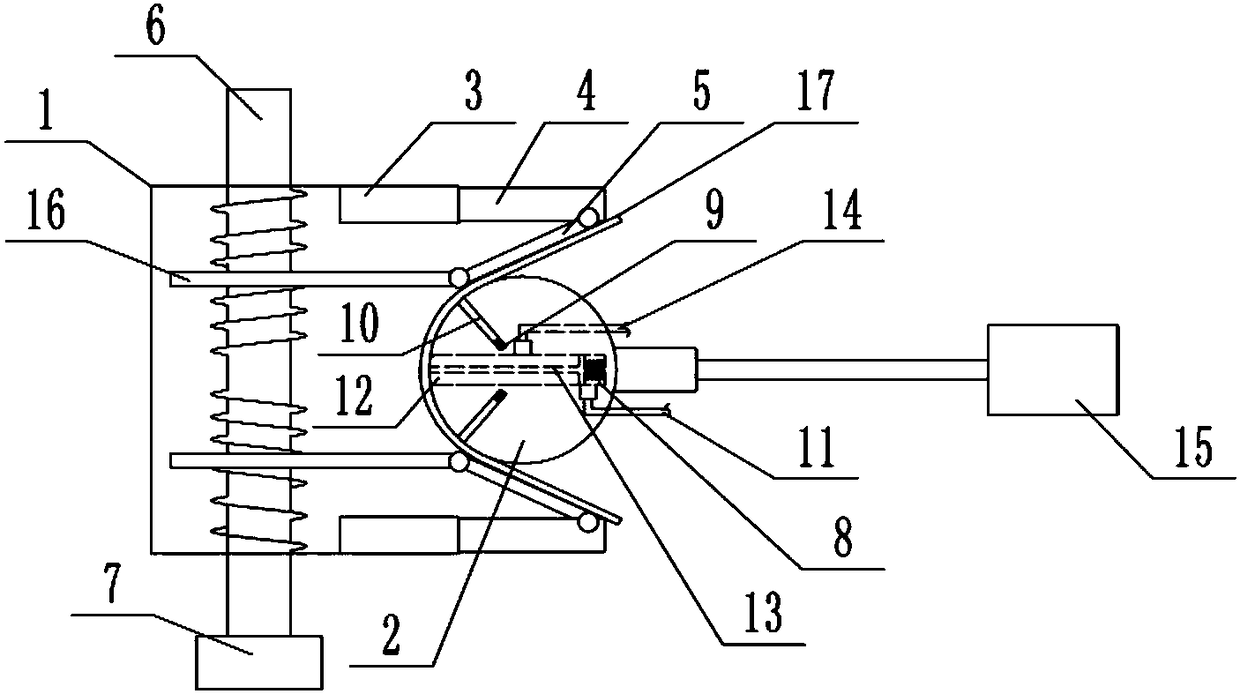

[0014] The reference signs in the drawings of the description include: positioning frame 1, bending roller 2, sliding seat 3, sliding plate 4, rotating plate 5, screw rod 6, motor 7, horizontal chute 8, chute 9, inclined plate 10, heating pipe 11. Contact 12, air outlet pipe 13, cooling pipe 14, hydraulic cylinder 15, support plate 16, guardrail 17.

[0015] Such as figure 1 , figure 2 As shown, a guardrail bending device includes in turn a horizontal positioning frame 1, a bending roller 2, and a first power mechanism that pushes the bending roller 2 to move along the center line of the positioning frame 1. The first power mechanism is a hydraulic cylinder 15, and the hydraulic pressure The piston rod of the cylinder 15 is fixedly connected with the bending roller 2; two sliding seats 3 are symmetrically connected by bolts on both sides of the positioning frame 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com