Novel cutting machine applicable to tunnel brick

A cutting machine and tunnel technology, which is used in stone processing tools, work accessories, manufacturing tools, etc., to achieve the effect of safe cutting, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

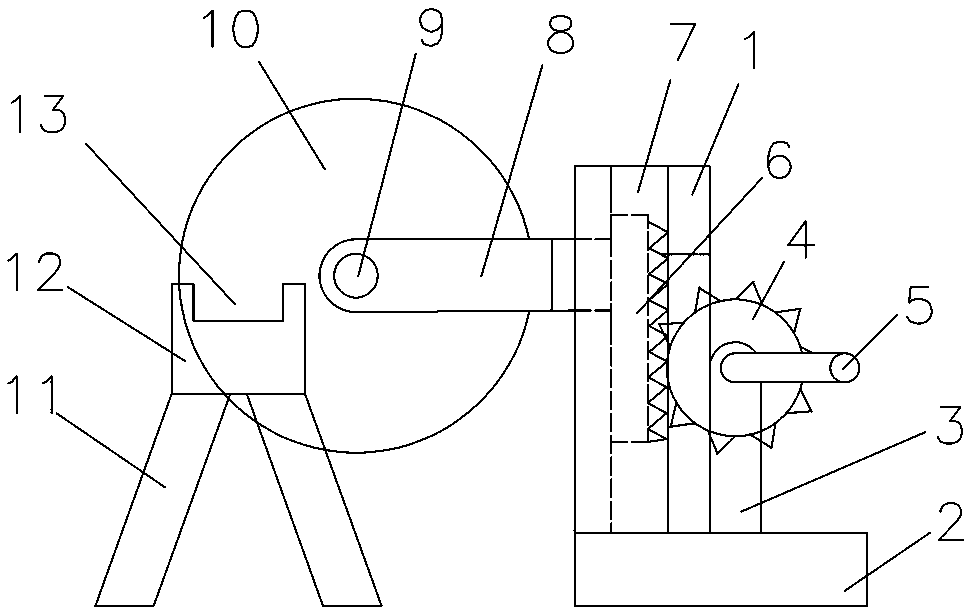

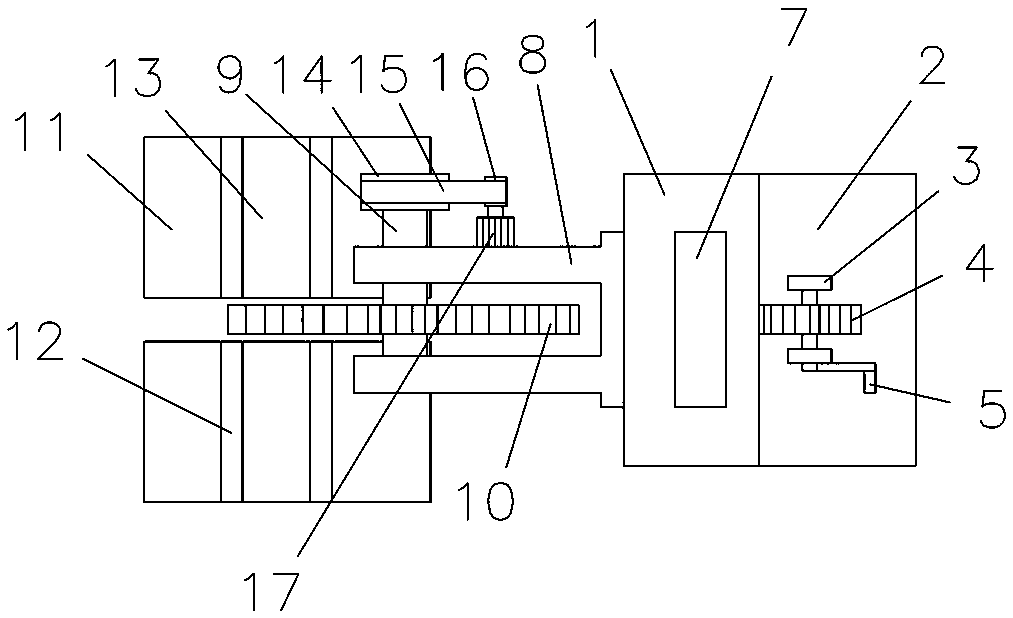

[0026] Example 1, such as Figure 1-2 Shown:

[0027] A new cutting machine for tunnel bricks, including a support frame 1, a base 2, a saw frame 8 and a saw blade 10, the support frame 1 is vertically installed on the base 2, and the right side of the support frame 1 is provided with a mounting frame 3 A gear 4 is rotatably installed in the mounting frame 3, and a rocker 5 is connected to one side of the gear 4; a chute 7 is arranged in the support frame 1, and a rack 6 is arranged in the chute 7, and the rack 6 The toothed side of 6 is matched with the rack 6 and installed, the other side of the rack 6 is fixedly connected with a saw frame 8, the outer end of the saw frame 8 is rotatably provided with a saw blade 10 through a rotating shaft 9, and one end of the rotating shaft 9 is provided with a second A pulley 14, the first pulley 14 is provided with a conveyor belt 15, the other end inside of the conveyor belt 15 is matched with a second pulley 16, and the second pulley...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com