Electromechanical integrated rapid flat screen printing equipment

A flat screen printing, electromechanical technology, applied in the field of mechatronic fast flat screen printing equipment, can solve the problems of expensive printing machines, inability to realize industrial automation, and low efficiency of manual printing, so as to improve the quality of screen printing and reduce Worker labor intensity, the effect of convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

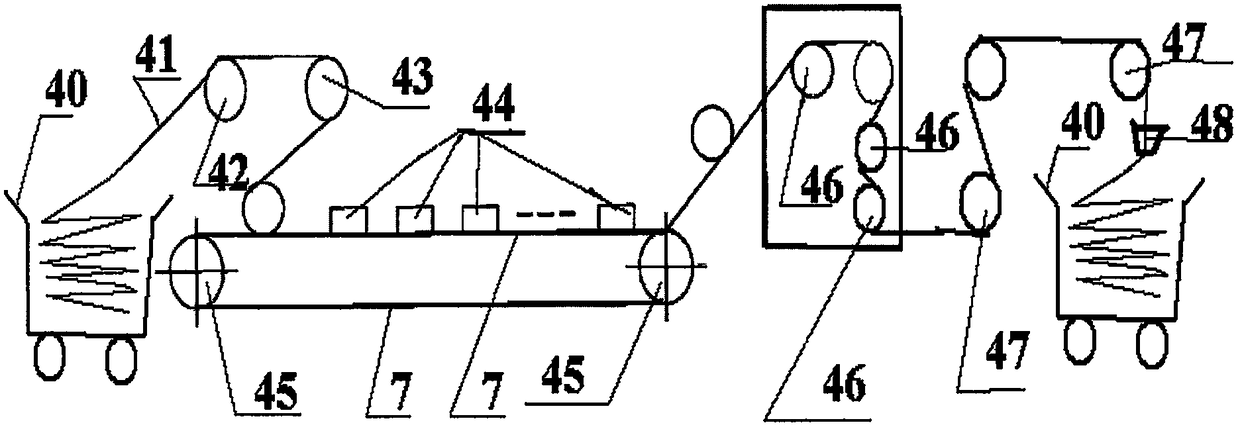

[0026] Such as figure 1 As shown, the cloth 41 that is boiled, bleached or dyed is placed in the cloth pushing trolley 40 on the left side, the cloth 41 passes through the edge suction device 42, and the curling and wrinkles of the cloth 41 are removed, and the flat unfolded cloth 41 passes through the opening Width threaded roller 43, described open-width threaded roller 43 is symmetrically distributed left and right helical threads on the surface of the roller body from the center to both sides, and the angle of rise of the left and right helical threads is 12~15 degrees; The described open width threaded roller The major diameter of 43 is 65mm. When the cloth 41 contacts the open-width threaded roller 43, friction occurs with the inclined threads on the roller surface, and the inclined threads expand the cloth 41 to both ends, so that the cloth 41 can be further flattened when printing. So that the printing unit 44 of the present invention can print on the stretched cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com