Automatic packaging machine

A packaging machine and conveying device technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, and increased production costs for cloth packaging, and achieve the elimination of manual labor, less error-prone, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in more detail by the following examples:

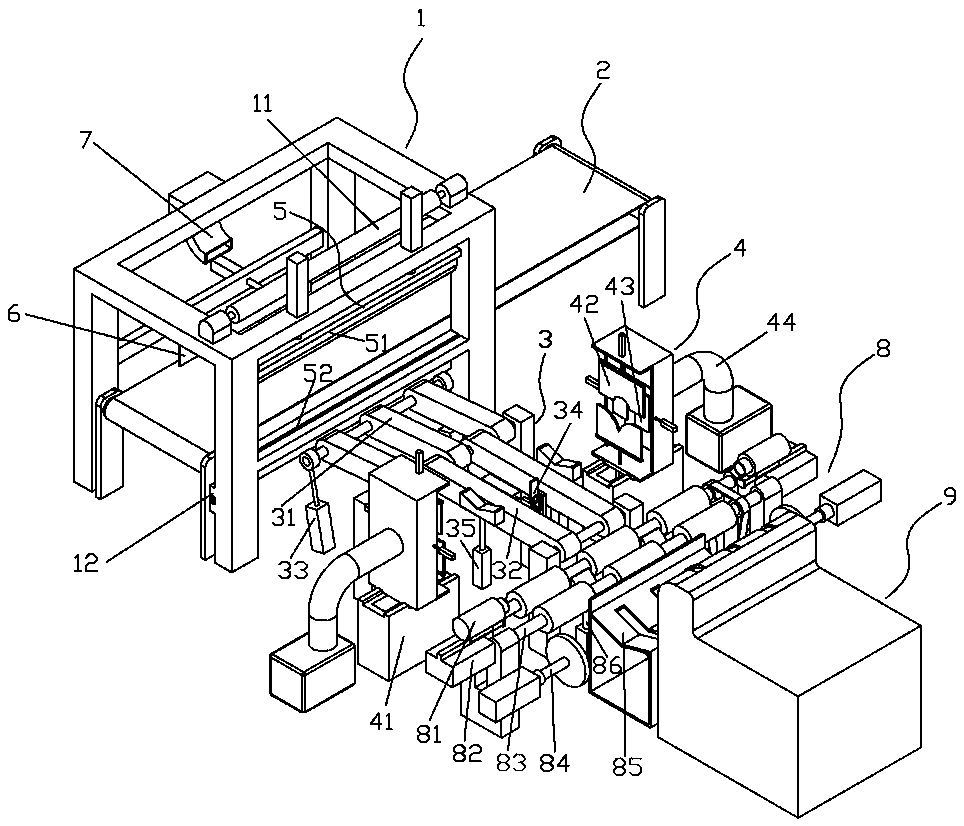

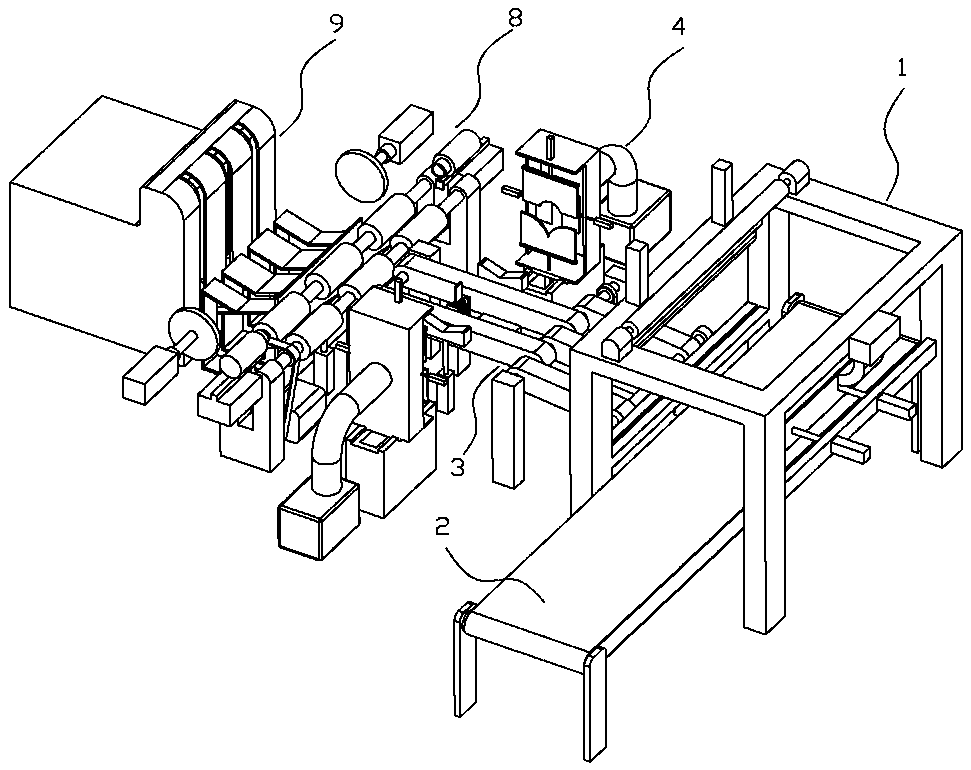

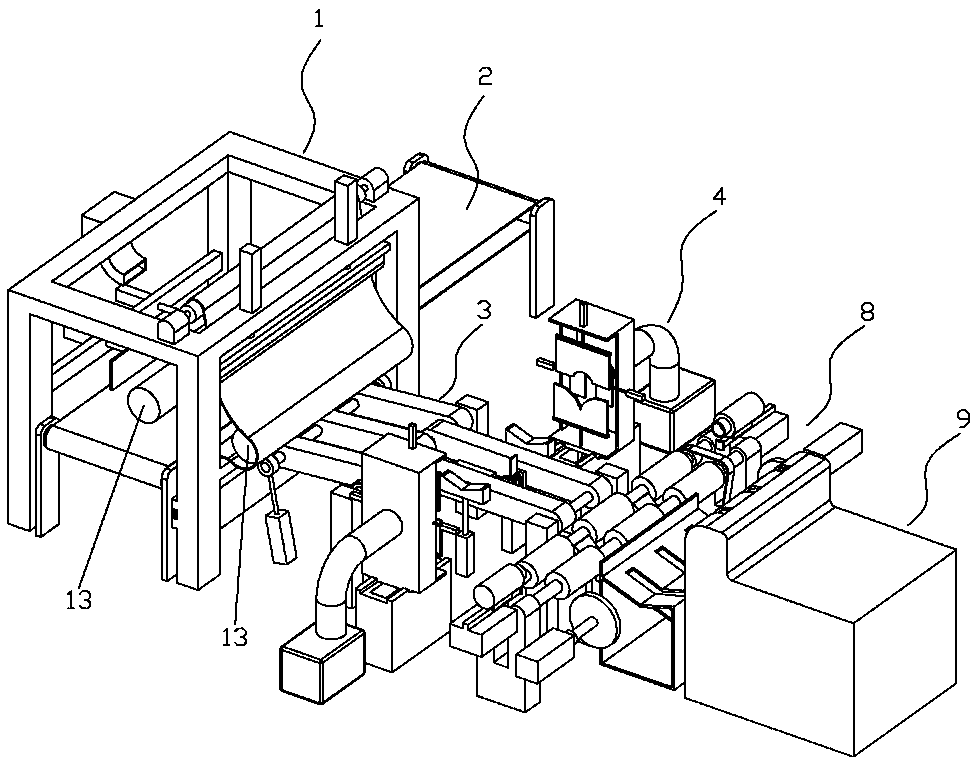

[0027] Such as figure 1 , 2 , 3, 4, 5, and 7, the present invention provides an automatic packaging machine, including feeding device 2, film release curtain 1, transfer device 3, sealing device 4, packaging device 8, film release curtain 1, transfer device 3 And encapsulation device 8 is arranged in sequence according to the conveying direction of cloth roller 13, film releasing curtain 1 is a gantry type door frame structure, and feeding device 2 is arranged below film releasing curtain 1, and the top of film releasing curtain 1 is provided with plastic film wrapped near the direction of conveying device 3. Put film roller 11, be provided with clamping film mechanism 12 correspondingly below film roller 11, put film roller 11 front ends and be provided with cutting device one 5, cutting device one 5 comprises lifting blade 51, and lifting blade 51 can scald plastic film, in The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com