Leather industry chromium-containing wastewater recycling treatment process system

A leather industry and treatment process technology, applied in the field of chromium-containing wastewater resource treatment process system in the leather industry, can solve the problems that the water quality is difficult to meet the standard, and the secondary pollution of water, inorganic salts, and chrome sludge cannot be carried out, etc., and achieve resource utilization. Recycling, significant treatment effect, and effective equipment and material resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

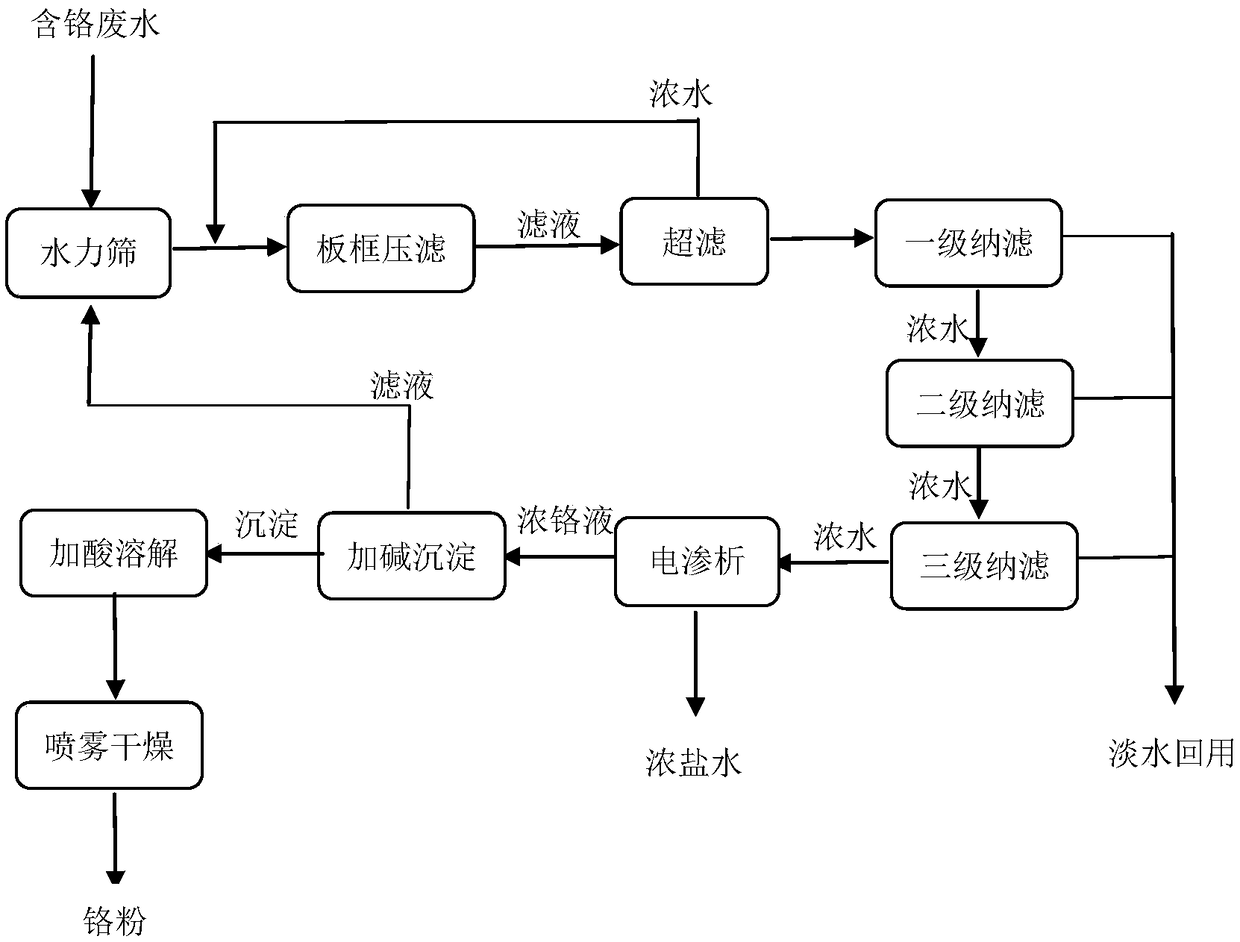

Method used

Image

Examples

Embodiment 1

[0024] The chromium-containing wastewater discharged from a leather tanning workshop in an enterprise has a Cr content of 30mg / L, a TDS of 3507mg / L, and a Ca content of 3507mg / L. 2+ The content is 24mg / L, Mg 2+ The content is 27mg / L, Cl - The content is 515mg / L, SO 4 2- The content is 1039mg / L, Na + The content is 712mg / L.

[0025] After the waste water containing chromium is removed by 0.5mm hydraulic sieve, it is separated into 5.0m 3 The / h flow rate enters the plate and frame filter press system for coarse filtration, the filtrate passes through the tubular ultrafiltration membrane for fine filtration, and the produced water enters the three-stage nanofiltration device, and the first-stage nanofiltration, second-stage nanofiltration and third-stage nanofiltration are recovered The ratios are 80%, 50%, and 50% respectively, and the final output of concentrated water in the nanofiltration system is 0.25m 3 / h, the Cr content is 595mg / L, and the fresh water output produ...

Embodiment 2

[0027] The chromium-containing wastewater discharged from a leather tanning workshop of an enterprise has a Cr content of 16mg / L, a TDS of 2715mg / L, and a Ca 2+ The content is 20mg / L, Mg 2+ The content is 46mg / L, Cl - The content is 760mg / L, SO 4 2- The content is 888mg / L, Na + The content is 785mg / L.

[0028] After the waste water containing chromium is removed by 0.5mm hydraulic sieve, it is separated into 5.0m 3 The / h flow rate enters the plate and frame filter press system for coarse filtration, the filtrate passes through the tubular ultrafiltration membrane for fine filtration, and the produced water enters the three-stage nanofiltration device, and the first-stage nanofiltration, second-stage nanofiltration and third-stage nanofiltration are recovered The ratios are 80%, 50%, and 50% respectively, and the final output of concentrated water in the nanofiltration system is 0.25m 3 / h, the Cr content is 317mg / L, and the fresh water output produced by the nanofiltrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com