Method and system for desalting and backwashing through electric absorption

An electro-adsorption and salt content technology, applied in the field of water treatment, can solve the problems of high water production rate, unable to guarantee the regeneration effect of the electro-adsorption module, etc., to achieve high water production rate, ensure long-term continuous and stable operation, and ensure the effect of regeneration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

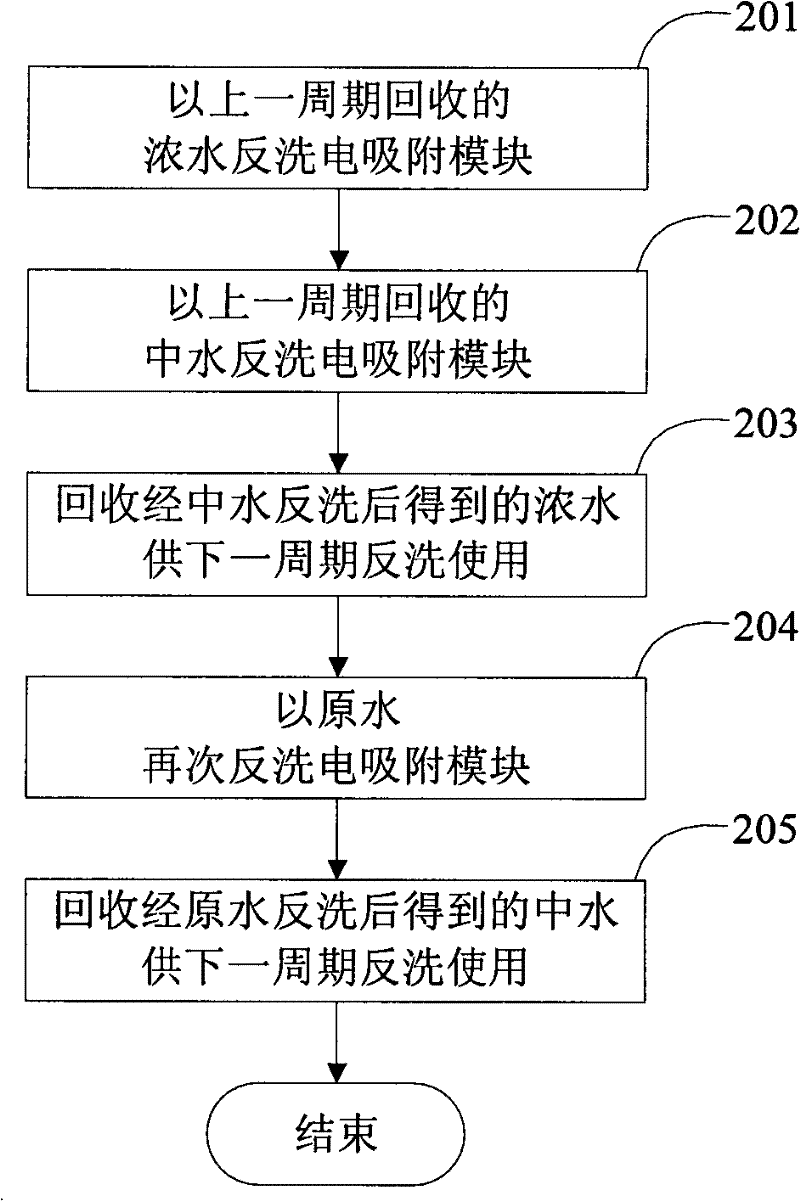

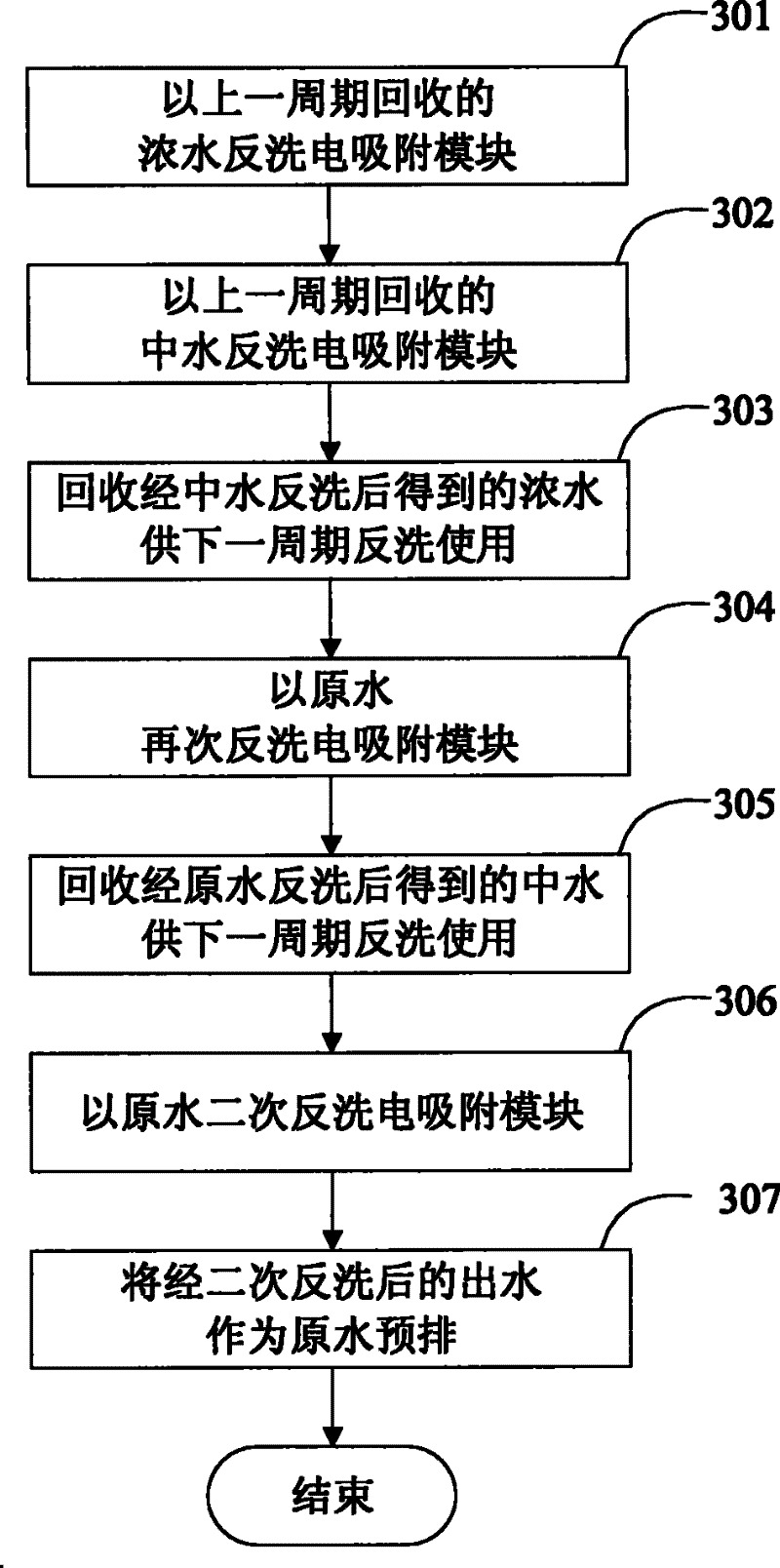

[0021] In order to improve the backwashing effect of the electro-adsorption module while ensuring the water production rate, the inventor studied the regeneration process and developed a four-stage backwash process, including concentrated water backwash, reclaimed water backwash, and raw water backwash. There are four sub-processes of washing and raw water pre-draining, and these four sub-processes can also be selected according to actual needs. It can not only ensure good regeneration of the electro-adsorption module, but also achieve a higher water production rate. The present invention will be described in detail below in conjunction with the drawings and embodiments.

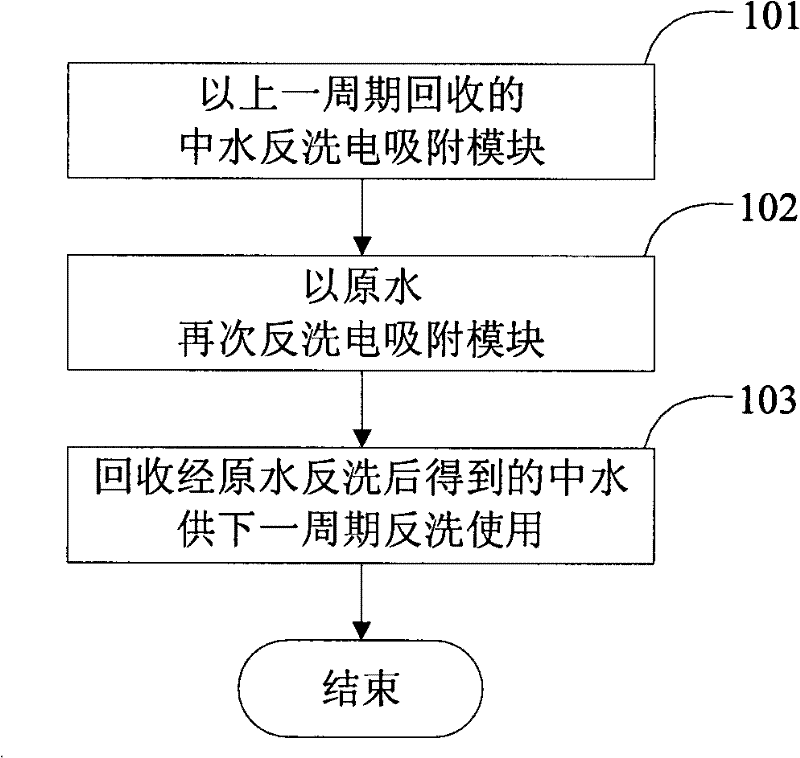

[0022] See figure 1 Shown is a flow chart of the electro-adsorption desalination and backwashing method according to an embodiment of the present invention, which includes the following main steps:

[0023] 101. The reclaimed water backwash electric adsorption module recovered in the previous cycle.

[0024] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com