Coarse denier raw yarn reeling machine

A silk reeling machine and raw silk technology, applied in the field of coarse denier raw silk reeling machines, can solve the problems of low efficiency and inability to achieve, and achieve the effects of high degree of automation, easy operation and high silk reeling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

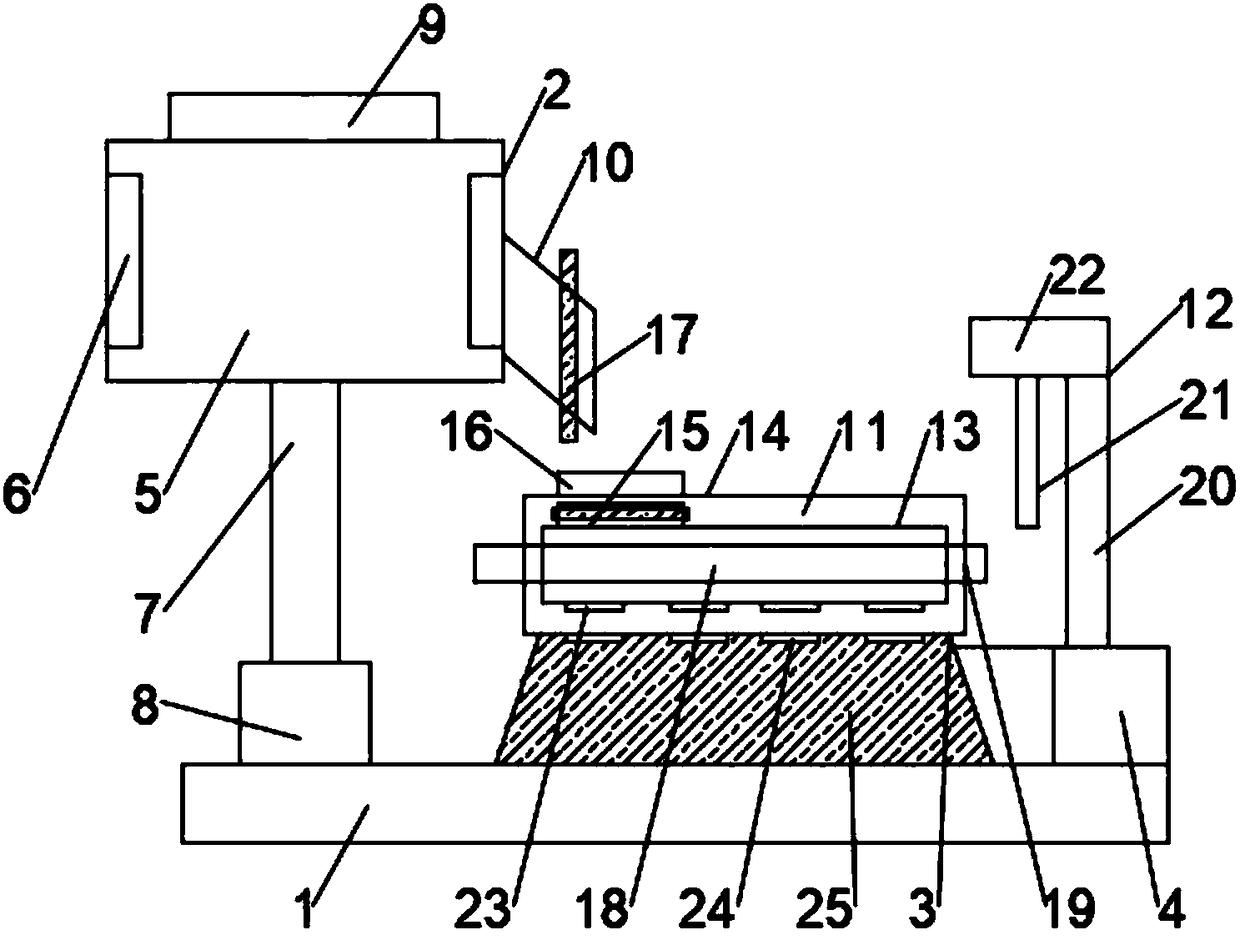

[0018] like figure 1 As shown, the present invention discloses a coarse denier raw silk reeling machine, comprising a base 1, which is fixed on the ground by screws, and is characterized in that: a drying device 2 and a silk reeling device 3 are arranged on the base 1. and a silk collecting box 4, the drying device 2 includes a drying box 5 and a dryer 6, the dryer 6 is arranged in the drying box 5, and the bottom end of the drying box 5 is provided with a first rotating shaft 7, the A motor 8 is connected to the bottom end of a rotating shaft 7, a feeding port 9 is provided at the top of the drying box 5, a discharging port 10 is provided on the right side wall of the drying box 5, and the reeling device 3 is provided at the discharging port On the right side of the port 10, fresh cocoons are put into the drying box 5 through the feeding port 9, and under the drying action of the dryer 6, the fresh cocoons are dried. The rotation of the rotating shaft 7 makes the drying effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com