Cutting equipment with flattening and dust removing performance for mask production and use method of cutting equipment

A cutting equipment and performance technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as poor cutting effect and ineffective smoothing, improve stability, avoid cloth wrinkles, and have strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

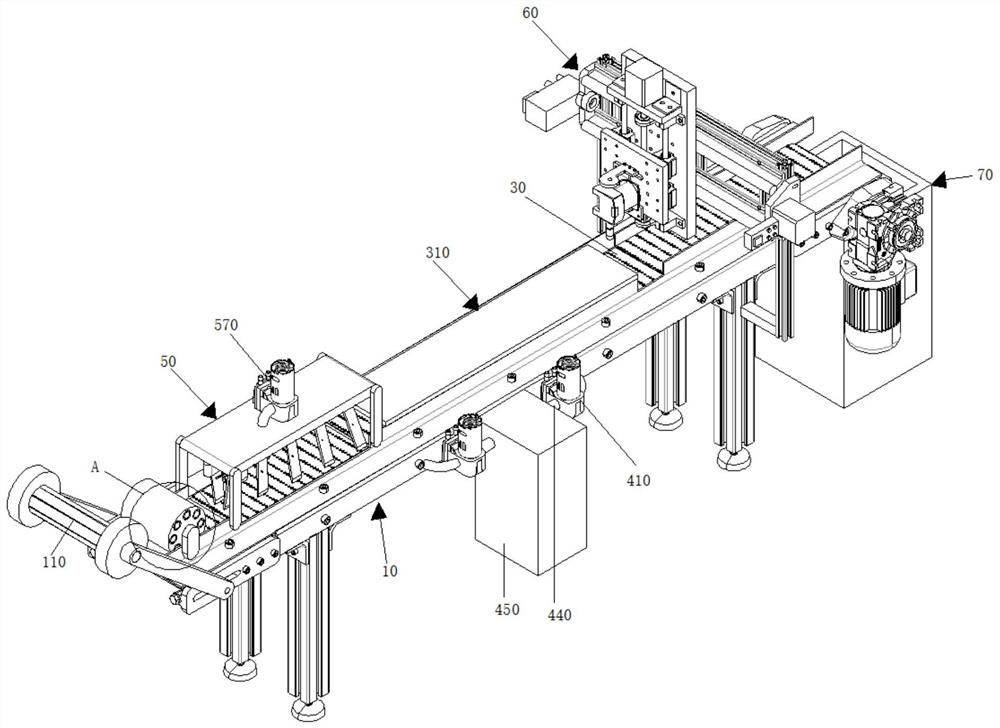

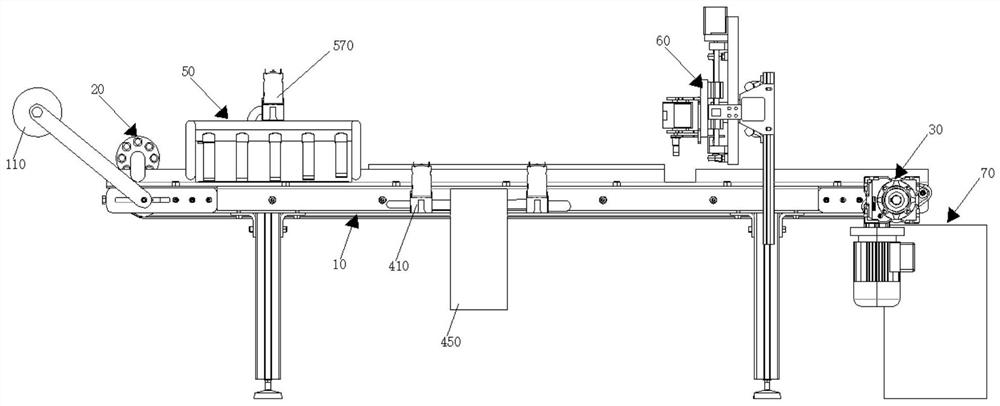

[0052] refer to Figure 1-10 , a cutting equipment for mask production with flattening and dust removal performance, comprising a frame 10, and also comprising:

[0053] The feeding roller 110 is installed on the front end of the frame 10 through the installation frame;

[0054] The heating roller 20 is installed at the front end of the frame 10, and is located above the frame 10;

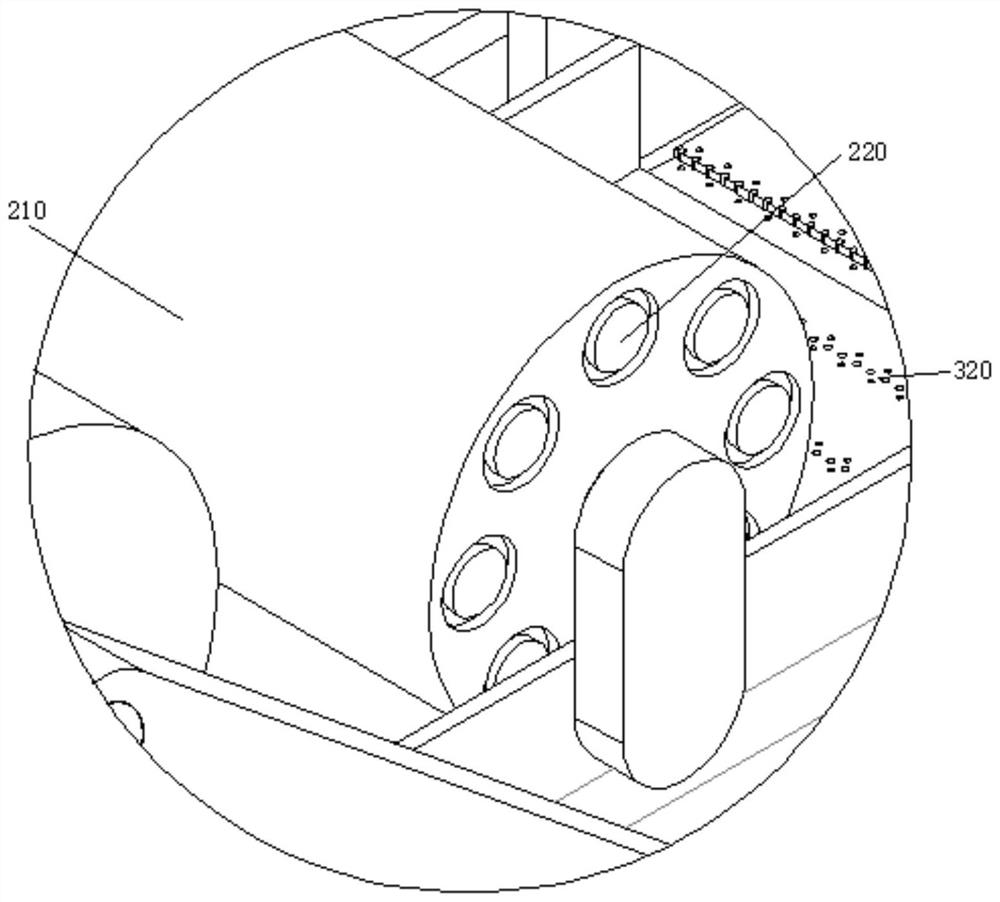

[0055] The conveyor belt 30 is installed on the frame 10, and the surface of the conveyor belt 30 is provided with a negative pressure adsorption hole 320 for conveying the cloth;

[0056] The negative pressure positioning adsorption mechanism 40 is installed on the frame 10 and located inside the conveyor belt 30;

[0057] The blowing leveling mechanism 50 is installed above the conveyor belt 30 and is located at the rear side of the feeding roller 110;

[0058] The cutting mechanism 60 is installed above the conveyor belt 30, and is located at the rear side of the blower leveling mechanism 50;...

Embodiment 2

[0069] refer to figure 1 and Figure 4 , a kind of cutting equipment for mask production with leveling and dust removal performance, which is basically the same as Embodiment 1, and further, a dust-proof casing is provided above the conveyor belt 30 between the blower smoothing mechanism 50 and the cutting mechanism 60 310 , the smoothed cloth enters under the cutting mechanism 60 through the conveying section protected by the dust-proof casing 310 to realize the function of dust-free conveying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com