A kind of polyester fiber spinning system

A spinning system and polyester fiber technology, applied in the field of dry spinning equipment, can solve the problems of inability to homogenize the spinning solution, use restrictions, and inability to distribute solvent vapors evenly, and achieve the goal of improving filtration efficiency and homogenization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

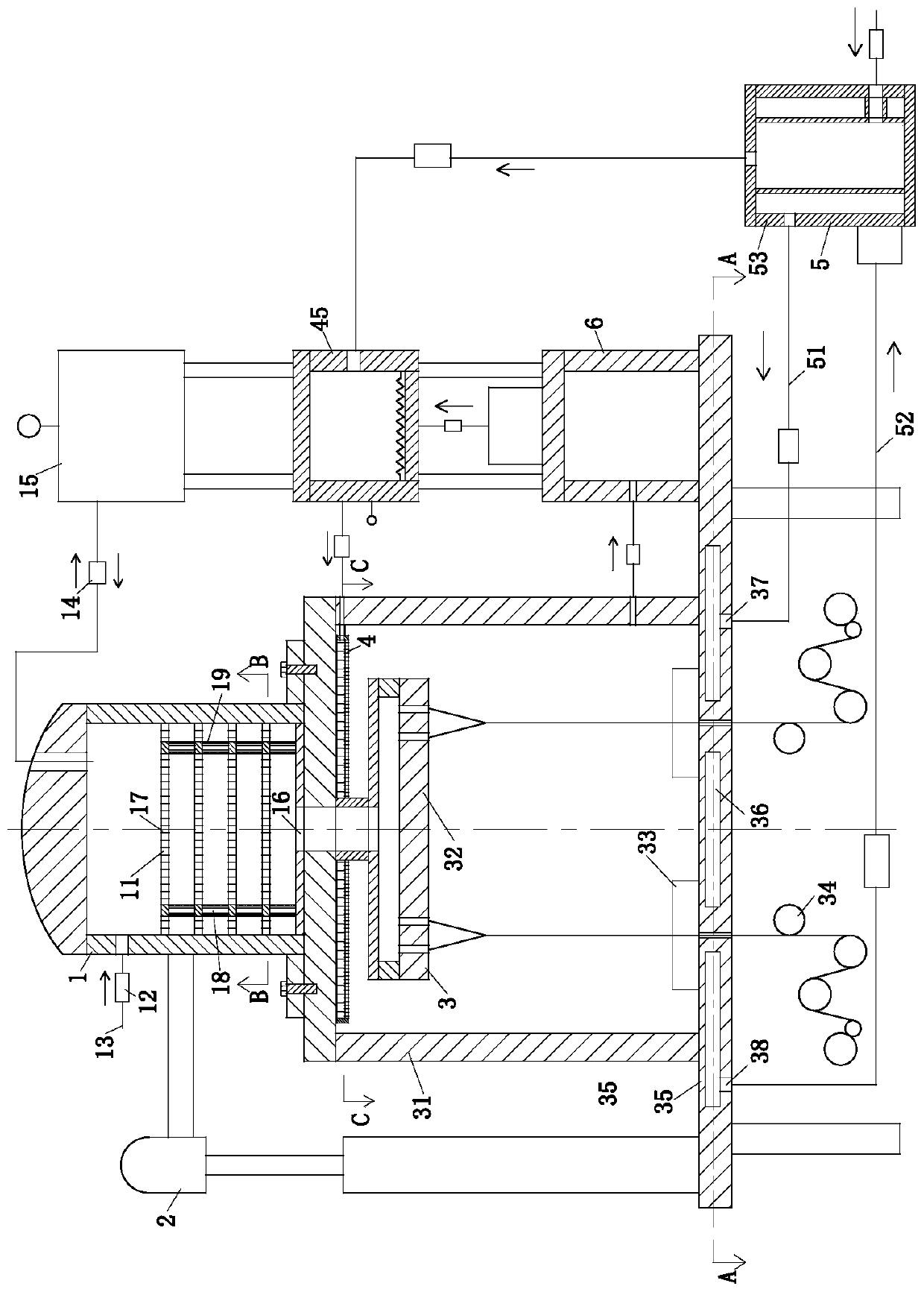

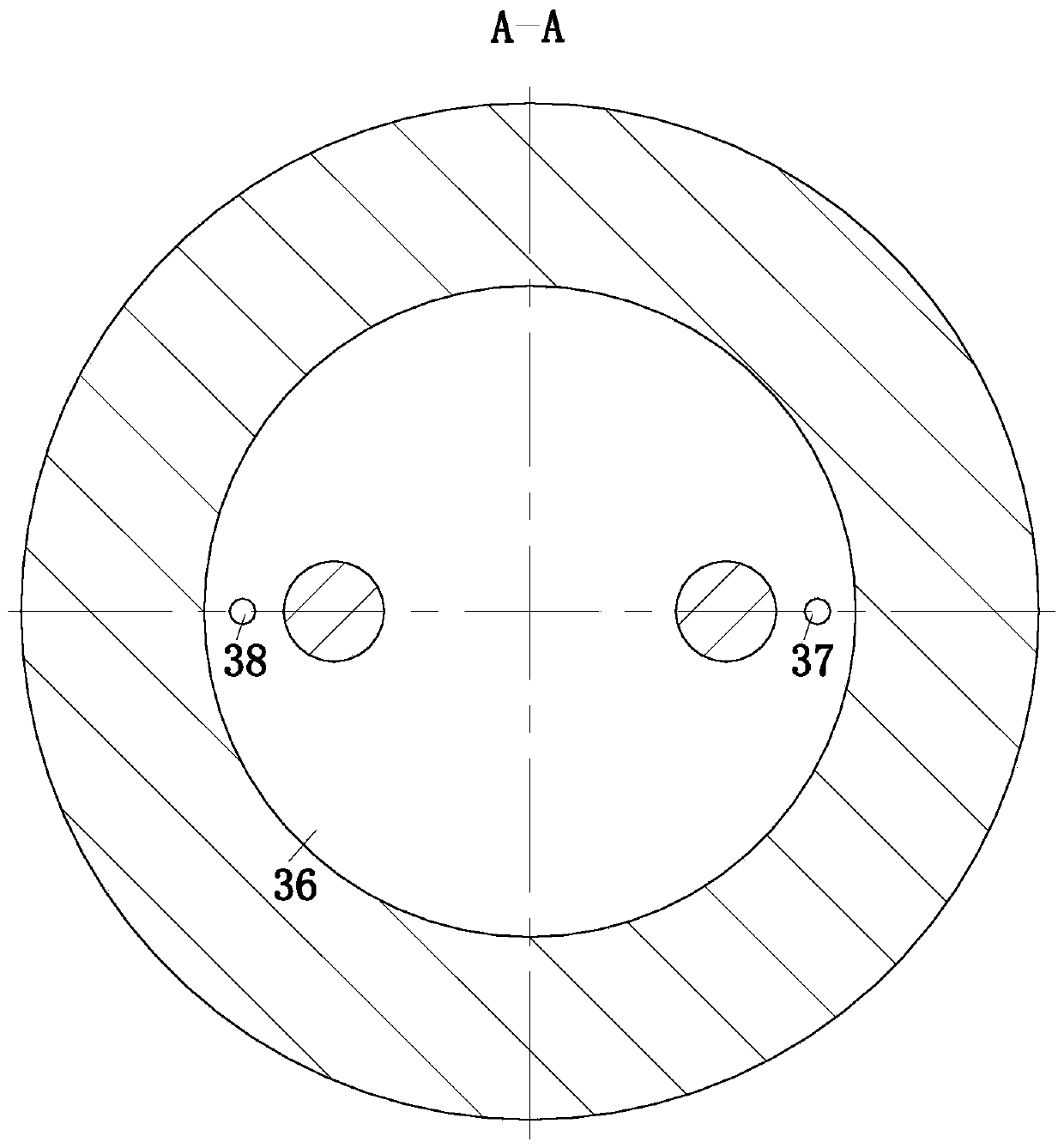

[0032] As an embodiment of the present invention, the spinning module 3 includes a sealed chamber 31, a spinneret 32, a false twist device 33 and a thread rolling device 34; the sealed chamber 31 includes a No. 1 upper bottom plate and a No. 1 side plate And the No. 1 lower base plate 35, the No. 1 upper base plate is fixedly installed on the upper surface of the No. 1 lower base plate 35 through the No. 1 side plate, and the sealed chamber 31 is used to create a closed space for spinning for making solvent vapor and inert gas to the fiber filaments. Carry out drying and hardening; the upper base plate is provided with No. 1 feed port 16 that penetrates to the feed module 1, and the No. 1 feed port 16 is provided with an automatic door, and the automatic door is used to control the opening of the No. 1 feed port 16. The spinneret 32 is fixedly connected with the No. 1 feed port 16 through a metal tube; the false twist device 33 is arranged on the upper surface of the lower bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com