Product transfer mechanism and automatic paper-model molding machine

A transfer mold and product technology, which is applied in the direction of textiles and papermaking, can solve the problems of low efficiency, damage to pulp molded products, and the inability to realize automatic production, so as to achieve the effect of expanding the scope of application, improving the degree of automation and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

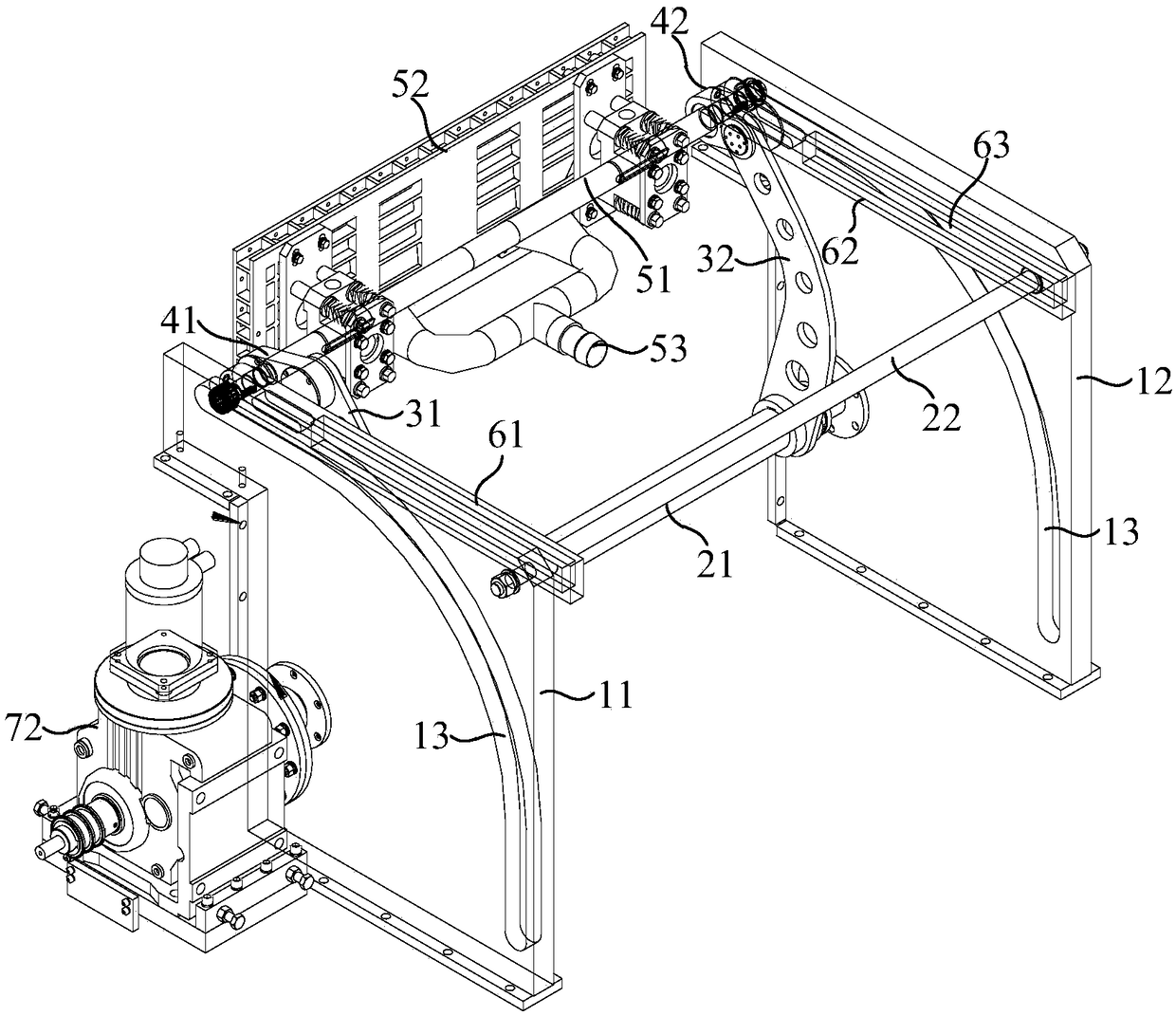

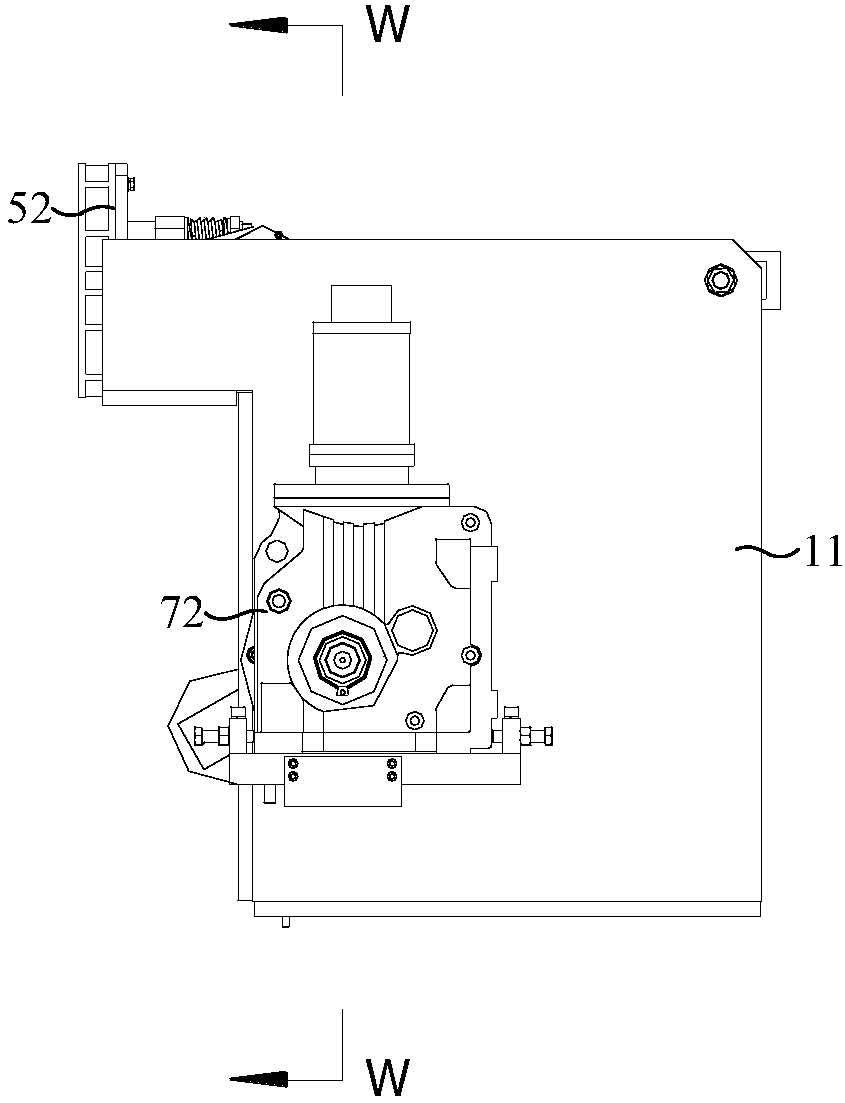

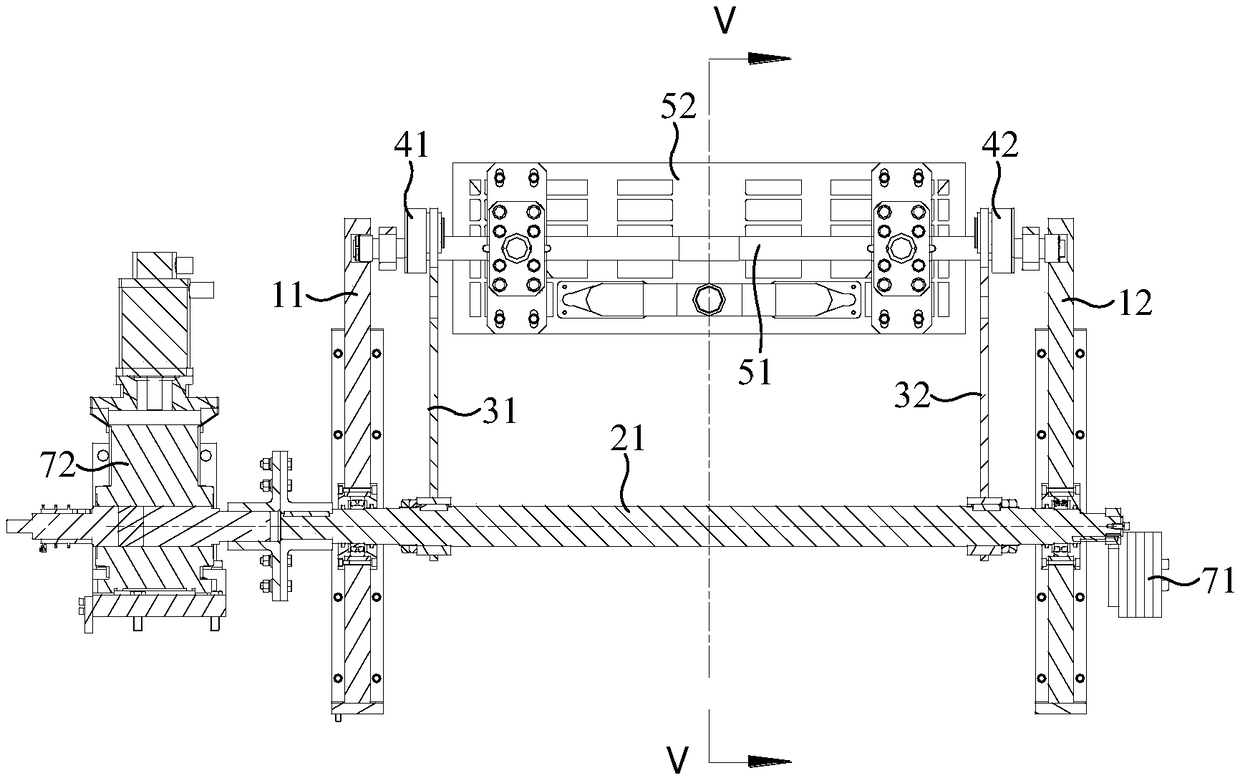

[0036] refer to Figure 1 to Figure 5 , the present invention provides a product transfer mechanism, the product transfer mechanism includes: a first guide plate 11 and a second guide plate 12, a rotating link 21 and a fixed link 22, a first curved swing arm 31 and a second curved swing arm 32. The first short link 41 and the second short link 42, the transfer link 51, the first guide slide 61 and the second guide slide 62, the product transfer mechanism can meet the transfer requirements of products of different heights, thereby expanding the equipment The scope of application, improve the automation of equipment.

[0037] Specifically, the first gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com