Frame hydraulic oil way

A hydraulic oil circuit and vehicle frame technology, applied in the field of vehicle frame hydraulic oil circuit, can solve problems such as low operating efficiency, unreasonable flow distribution of brake gear pump oil circuit and main pump oil circuit, uncoordinated actions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

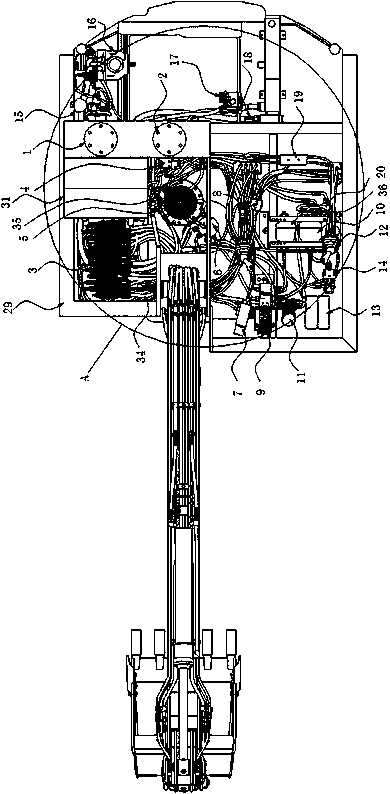

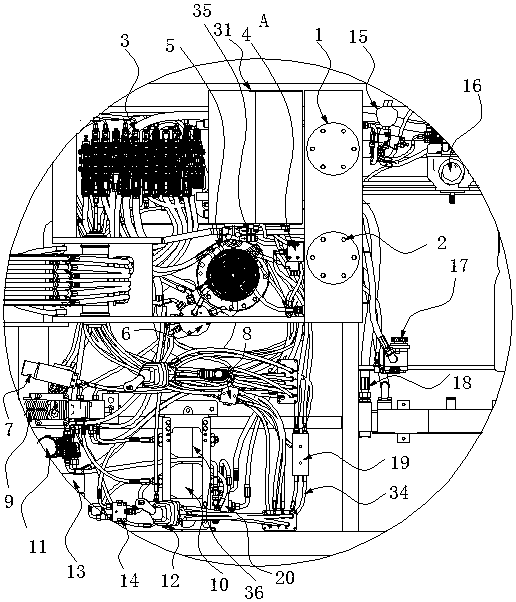

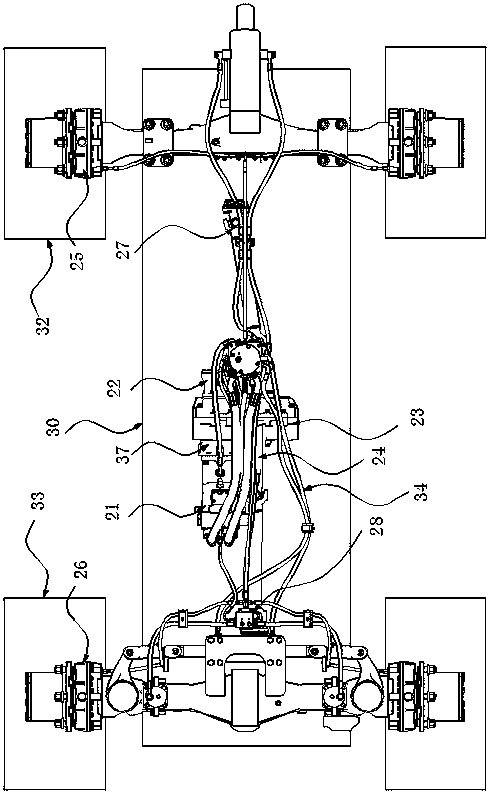

[0020] Frame hydraulic oil circuit, such as Figure 1 to Figure 4 As shown, including the hydraulic oil circuit of the upper frame and the hydraulic oil circuit of the lower frame.

[0021] The upper frame hydraulic oil circuit includes oil suction filter 1, oil return filter 2, oil tank 31 all arranged on upper frame 29, multi-way valve 3, high-speed shift valve 4, low-speed shift valve 35, and rotary motor 5 , central rotary joint 66, travel reversing valve 7, rotary shuttle valve 8, two-way brake valve 9, front diaphragm accumulator 10, rear diaphragm accumulator 10, hydraulic steering gear 11, parking brake control valve 12 , Fixture foot valve 13, double one-way valve 14, pilot oil source valve 15, main pump 16, brake gear pump 17, back pressure valve 18, oil collection block 19, liquid filling valve 20, pilot handle, left and right bridge Plate, accelerator control valve, accelerator pump.

[0022] Oil tank 31 is connected with oil suction filter 1 through oil pipe 34,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com