Gas tightness detection device for fuel cell stacks

A fuel cell stack and air tightness detection technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the increase and deceleration rate of fluid, etc., can solve the problem of uneven stack detection quality and affect fuel cells. performance, the stack cannot be used normally, etc., to achieve the effect of flexible use, fast and sensitive detection process, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

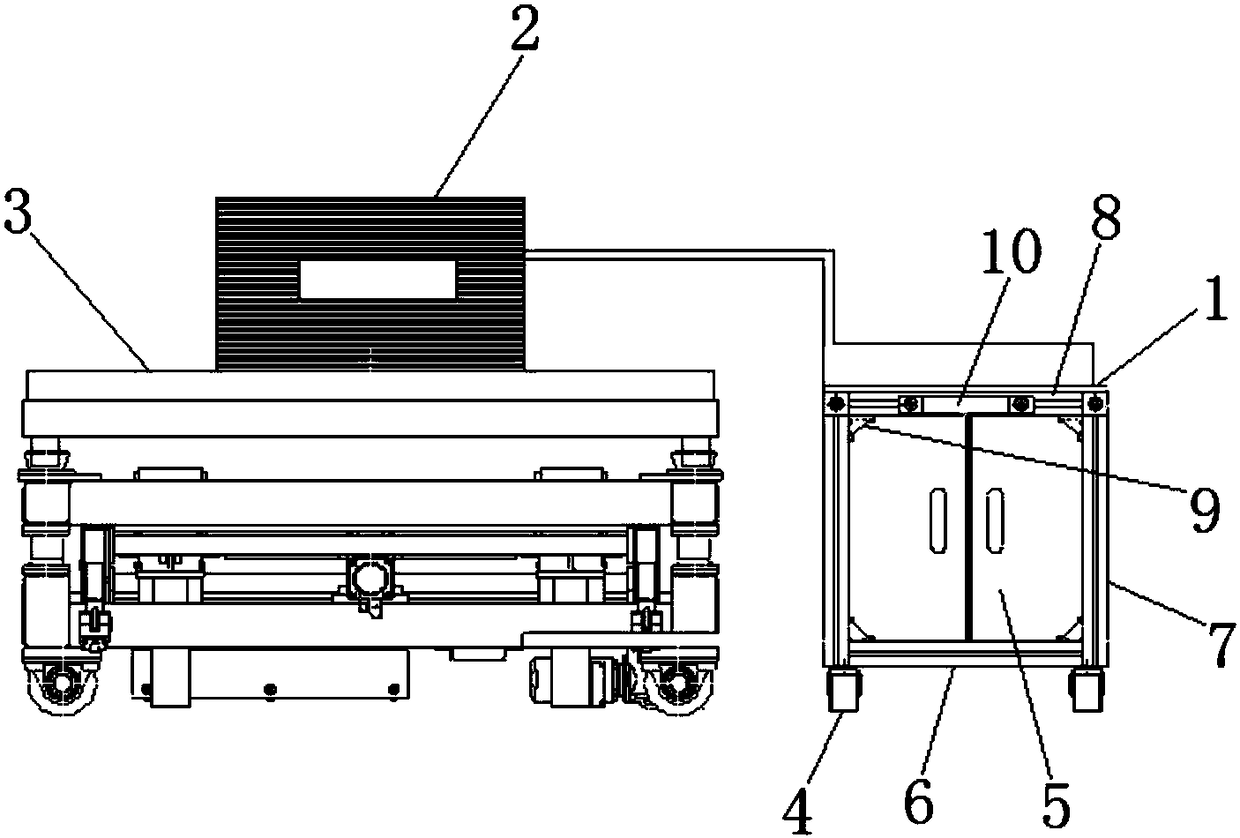

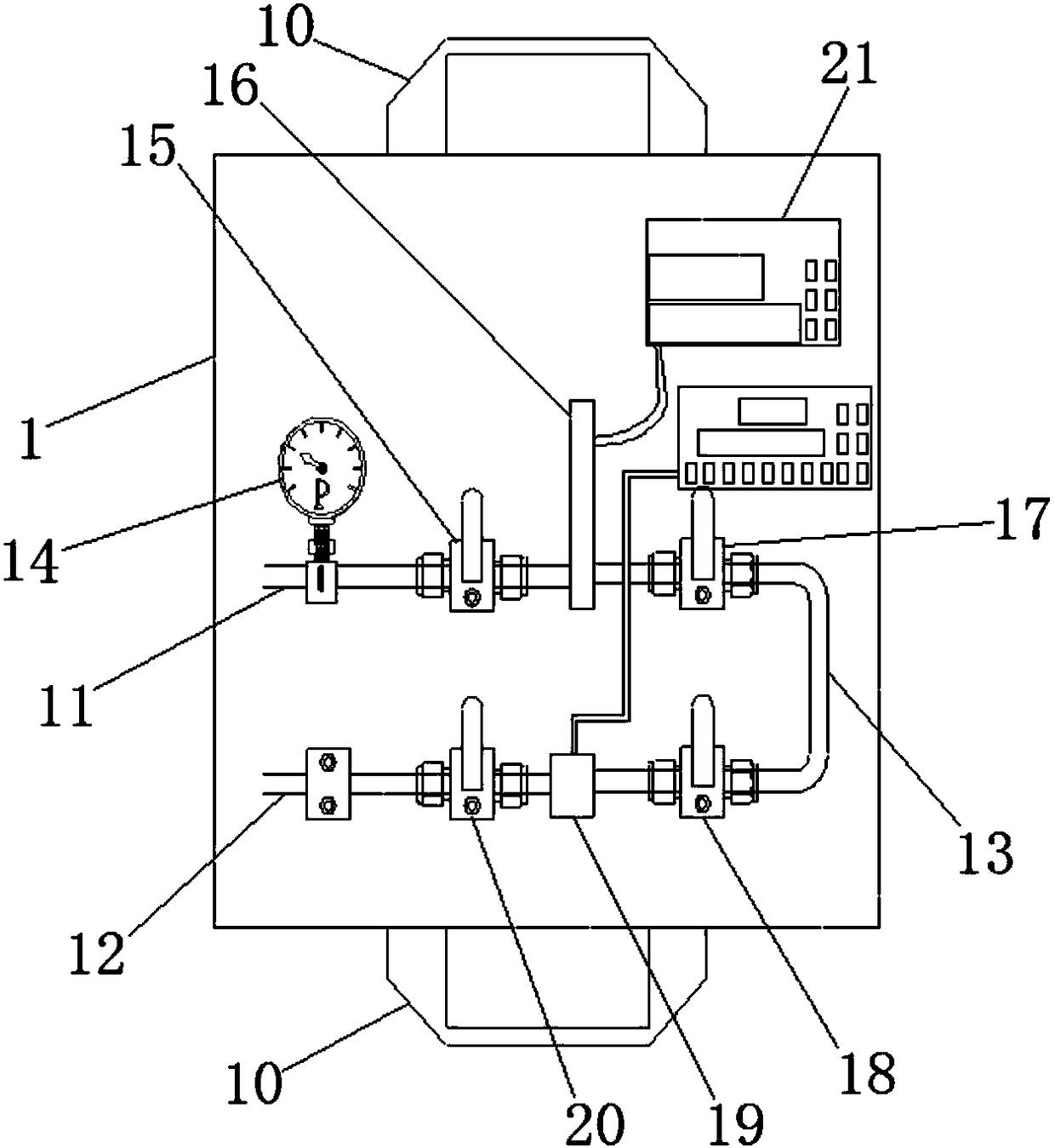

[0032] Such as figure 1 An airtightness detection device for a fuel cell stack is shown, which includes a movable support frame, a fixed plate 1 arranged on the top of the movable support frame, and an airtightness detection unit arranged on the fixed plate 1 , the mobile support frame is provided with a gas storage cylinder connected with the air tightness detection unit, and the fuel cell stack 2 is connected with the air tightness detection unit, and the air tightness detection unit is connected to the air tightness of the fuel cell stack 2 to test.

[0033] Wherein, the fuel cell stack 2 is arranged on the stack placement platform 3 .

[0034] The mobile supporting frame includes a frame body, universal wheels 4 arranged at the bottom of the frame body, and a locker 5 arranged on the frame body, and the gas cylinder is arranged in the locker 5 . The frame body includes a bottom plate 6, a pair of side plates 7 arranged side by side on the bottom plate 6, and a top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com