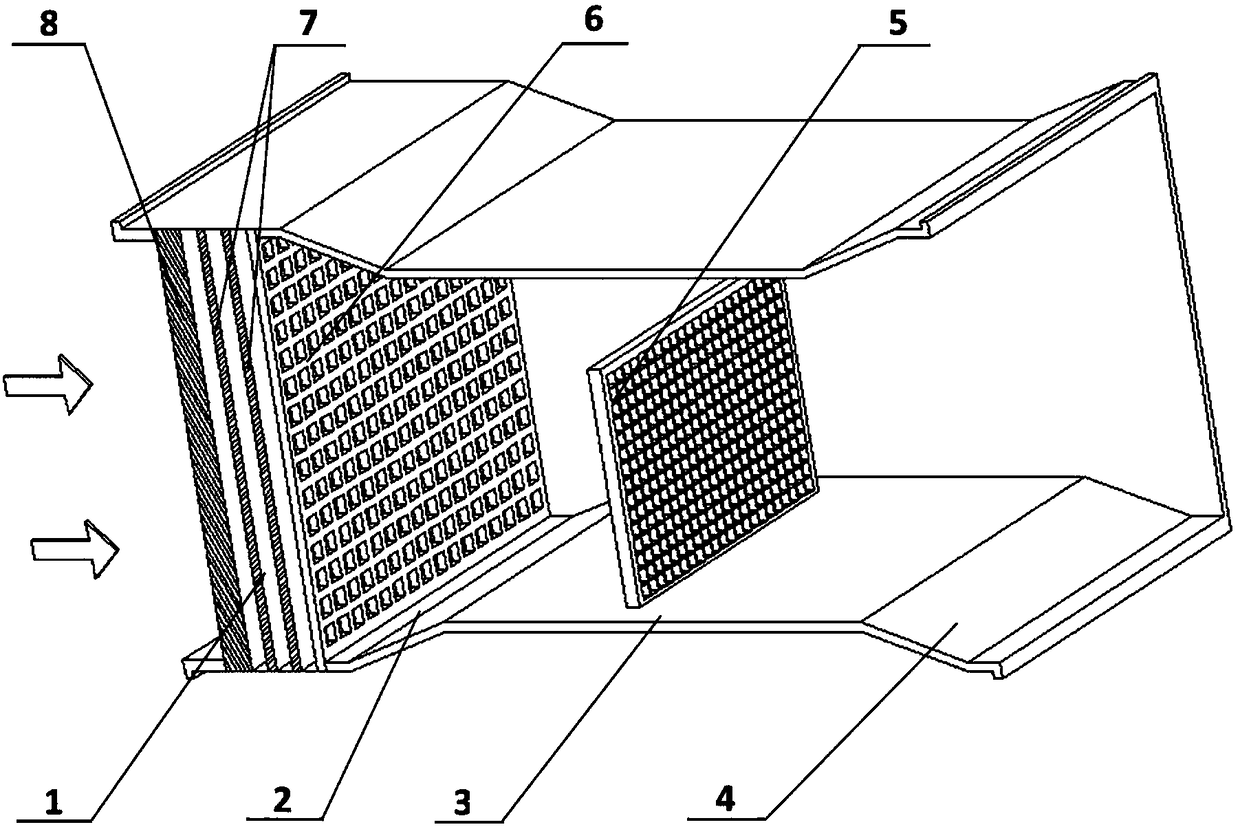

Artificial porous barrier model positioning and installation device for wind tunnel test

A positioning and installation, wind tunnel test technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of low test efficiency, low adjustment accuracy, complicated operation, etc. Strong, improve test efficiency, flexible control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

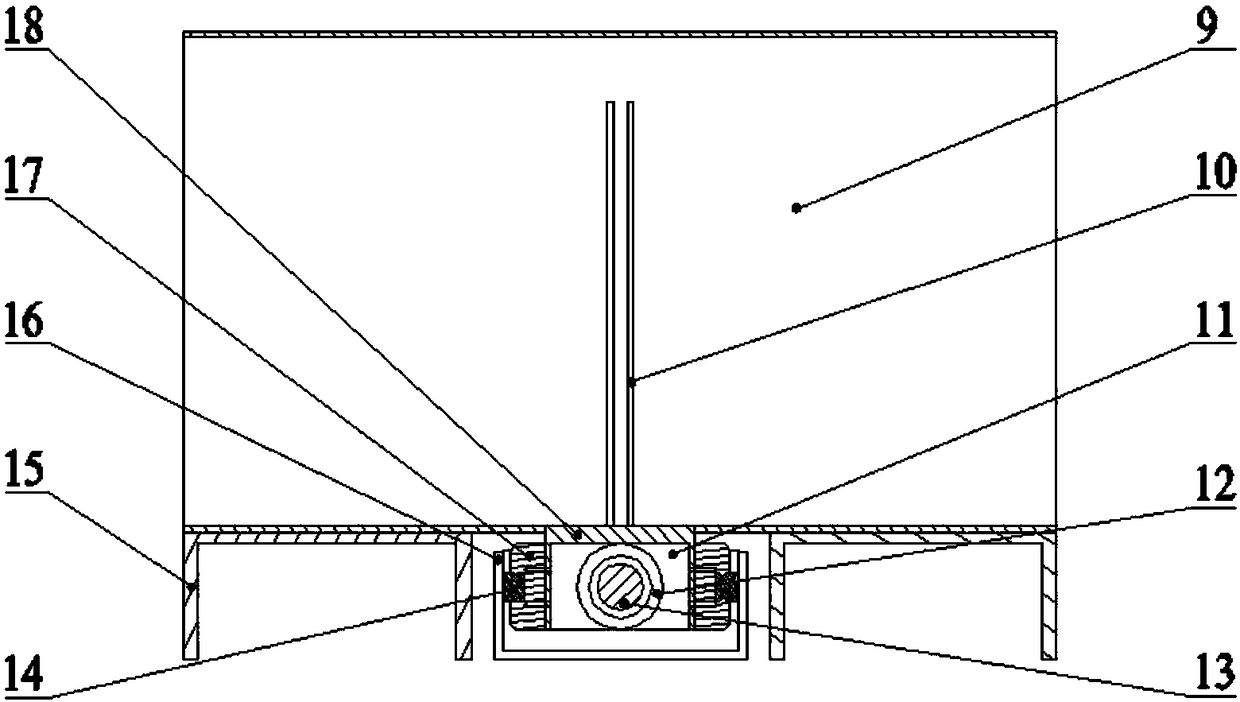

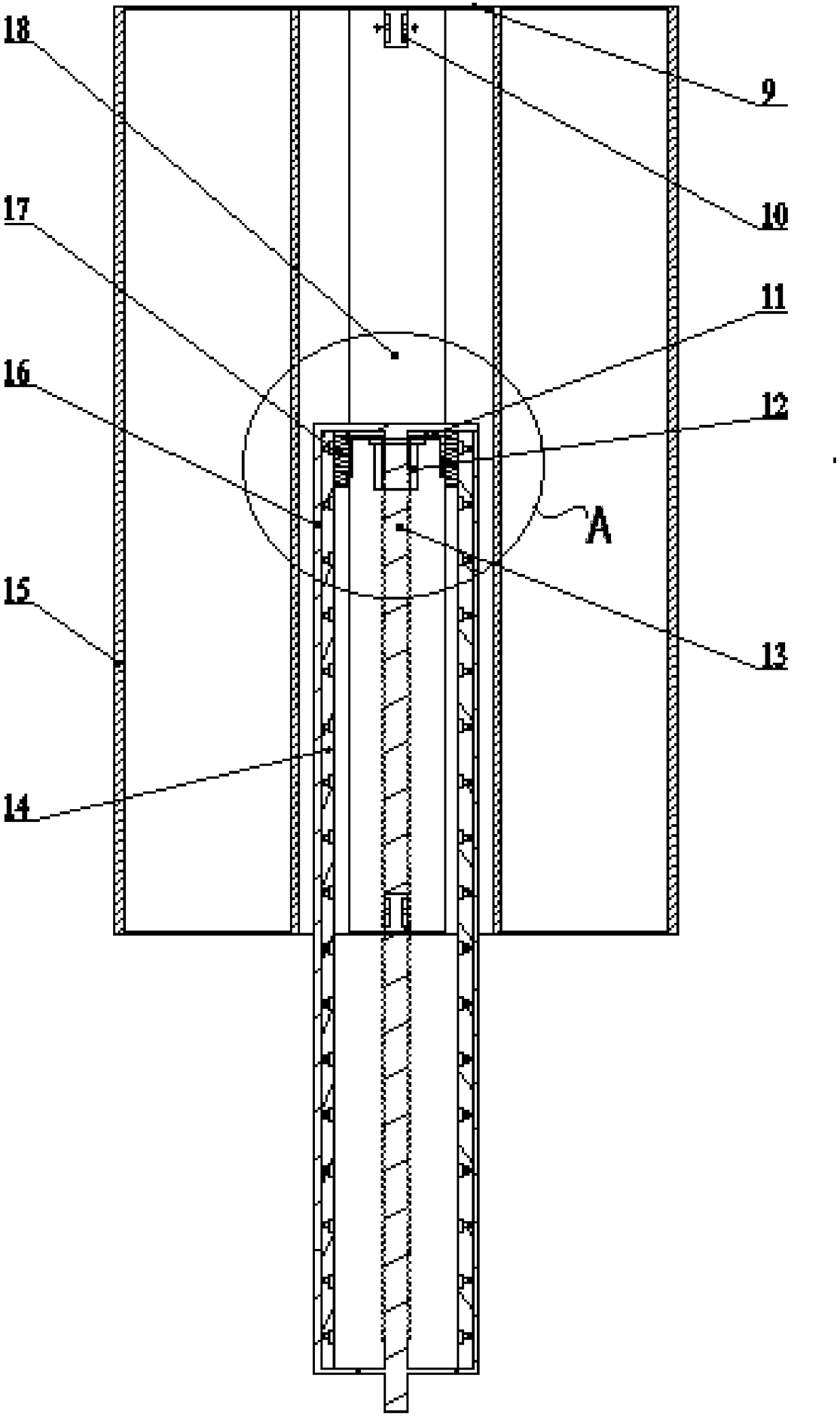

[0040] In order to further illustrate the beneficial effects brought by the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0041] Such as figure 2 and Figure 5 As shown, the artificial porous barrier model positioning and installation device for wind tunnel test of the present invention corresponds to the position of the transparent test chamber 9 of the wind tunnel test system, wherein, the artificial porous barrier formed by the support stand 10 and the support base plate 18 Driven by the linkage mechanism below it, the clamping mechanism of the porous barrier model moves forward and backward in the horizontal direction, so that the artificial porous barrier model can freely advance to the designated position of the transparent test chamber 9, or withdraw from the transparent test chamber 9, and the control process is flexible And the movement is stable and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com