Vision-based metal surface defect detection method

A metal surface and defect detection technology, applied in the direction of optical testing flaws/defects, measuring devices, material analysis through optical means, etc., can solve problems such as line marks, oil stains, and gaps on the surface of bullet casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail and complete below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

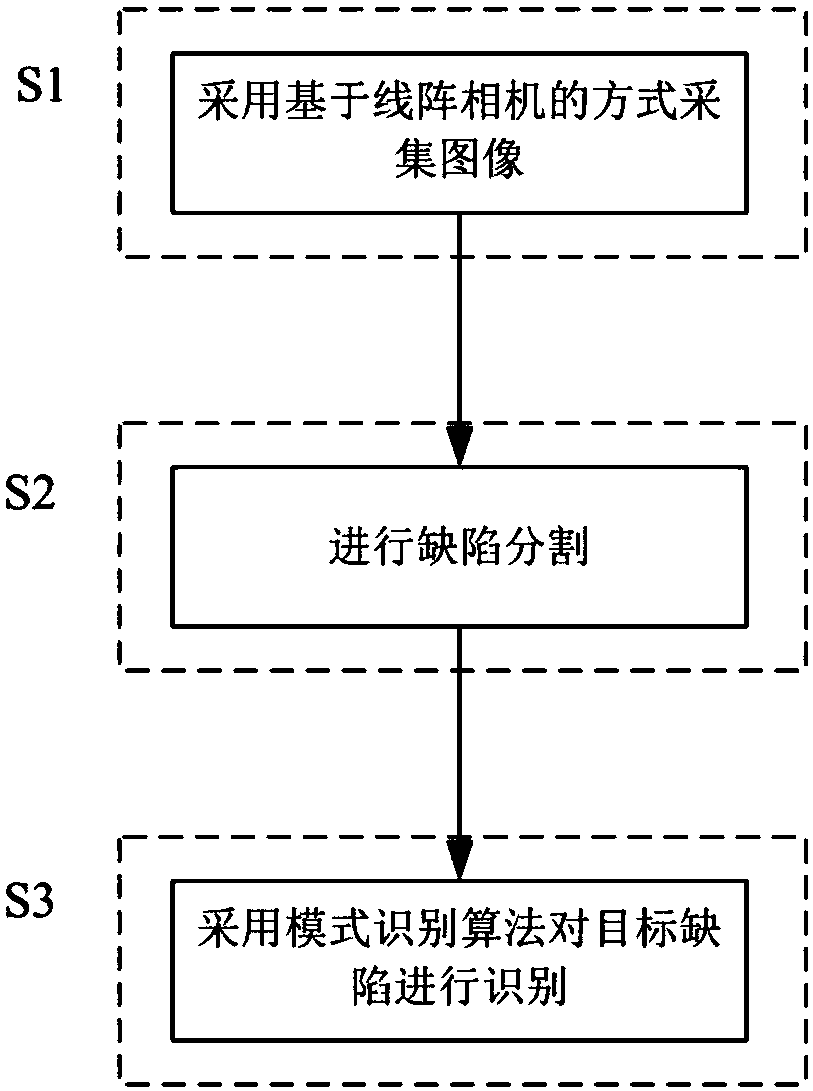

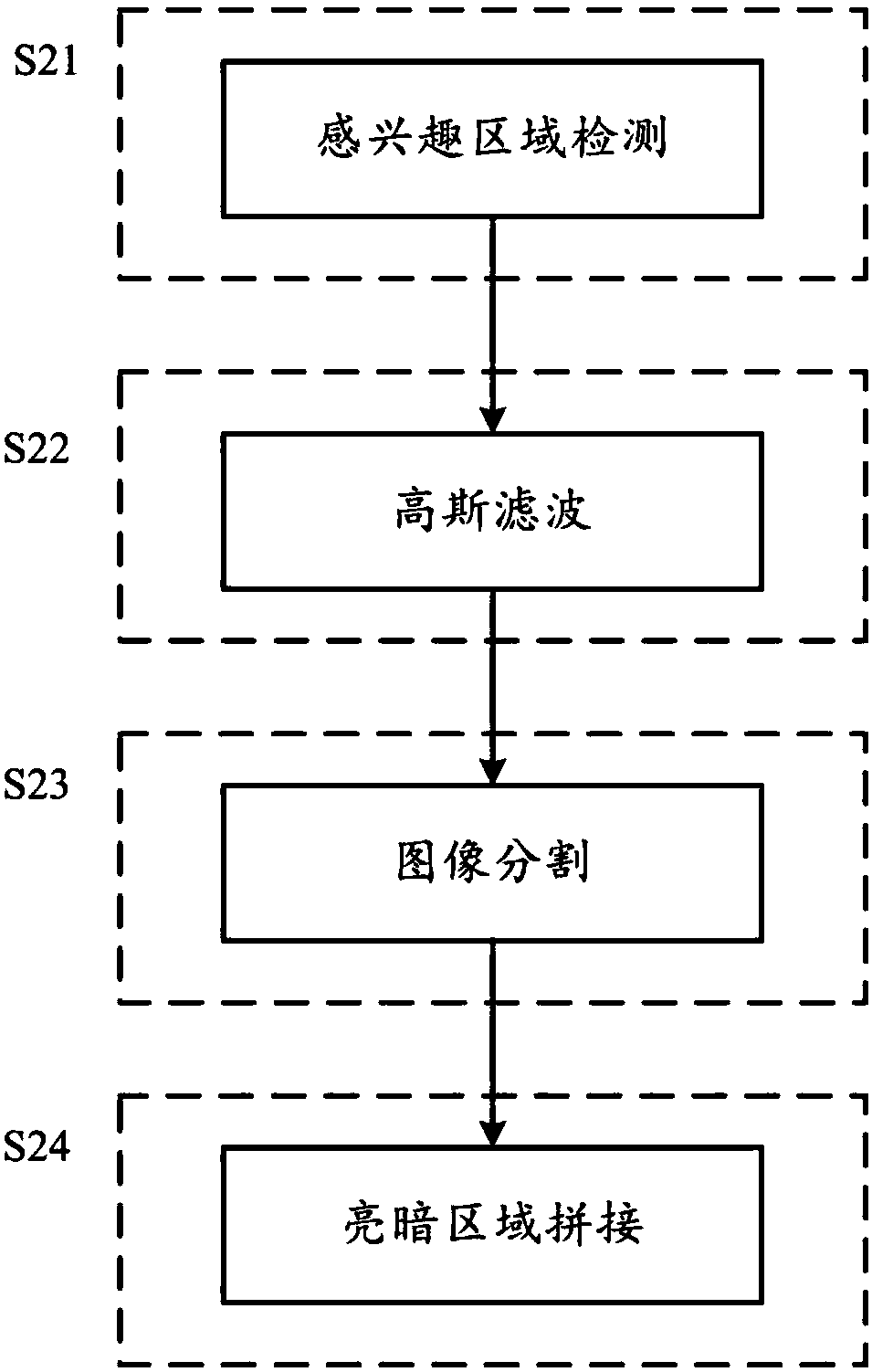

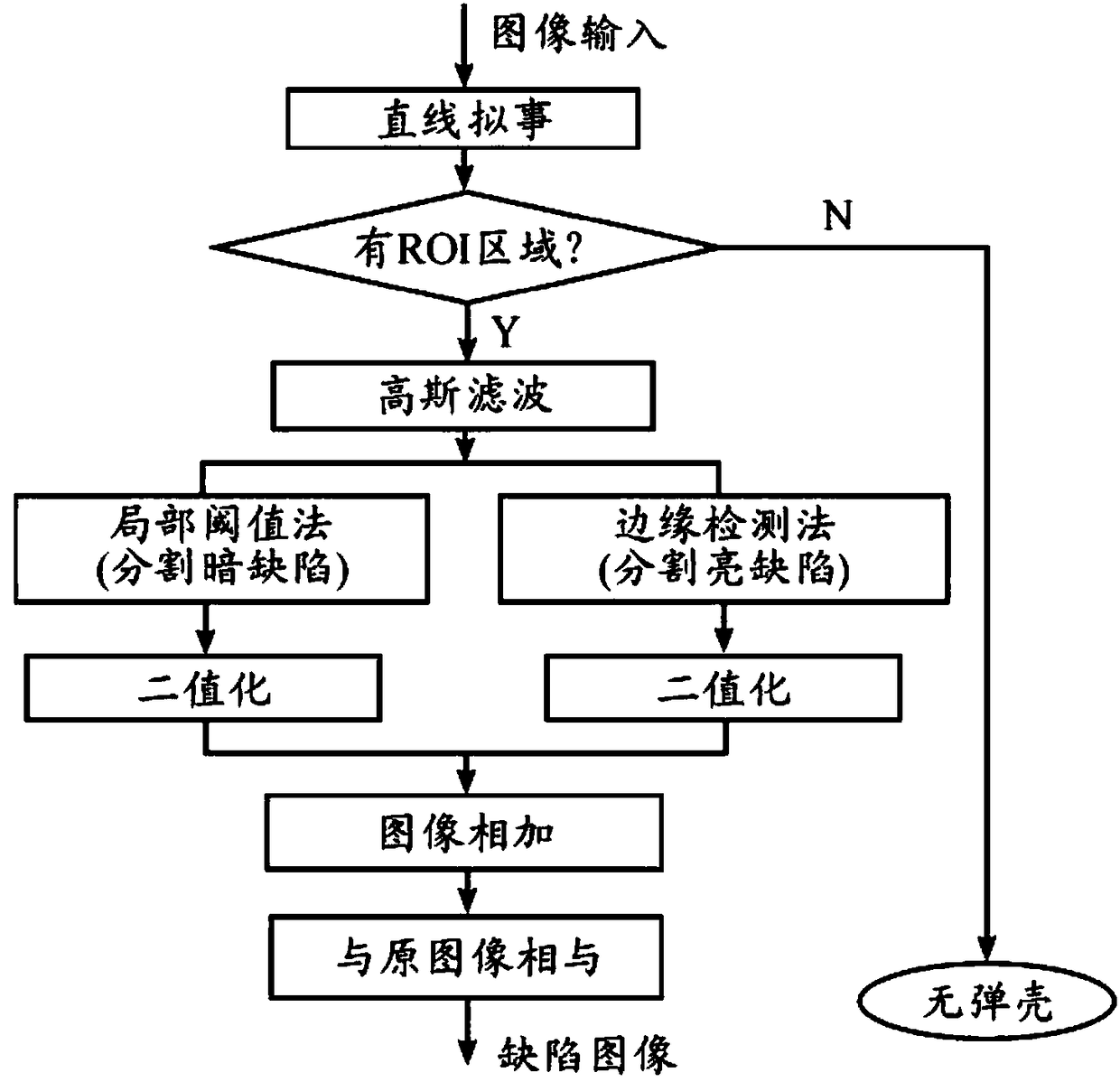

[0018] like figure 1 Shown, a kind of vision-based metal surface defect detection method of the present invention comprises the following steps:

[0019] S1, using a method based on a line scan camera to collect images. Due to the curved surface and material of the cartridge case, strong reflections will occur when the light hits the surface, and the slight swing of the cartridge case will affect the amount of light entering. Ordinary light sources or a single line light source cannot make the surface brightness of the cartridge case uniform. The detection system uses two white line light sources to illuminate the cartridge case from the left and right sides, one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com