Vibration type corn ear picking roller

A technology of picking ear rollers and corn, which is applied in the field of agricultural machinery, can solve the problems of not changing the working principle of pulling and picking ears, affecting the working reliability of corn harvesters, and blockage of ear picking platforms, achieving good market prospects, simple structure, Reduce the effect of gnawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

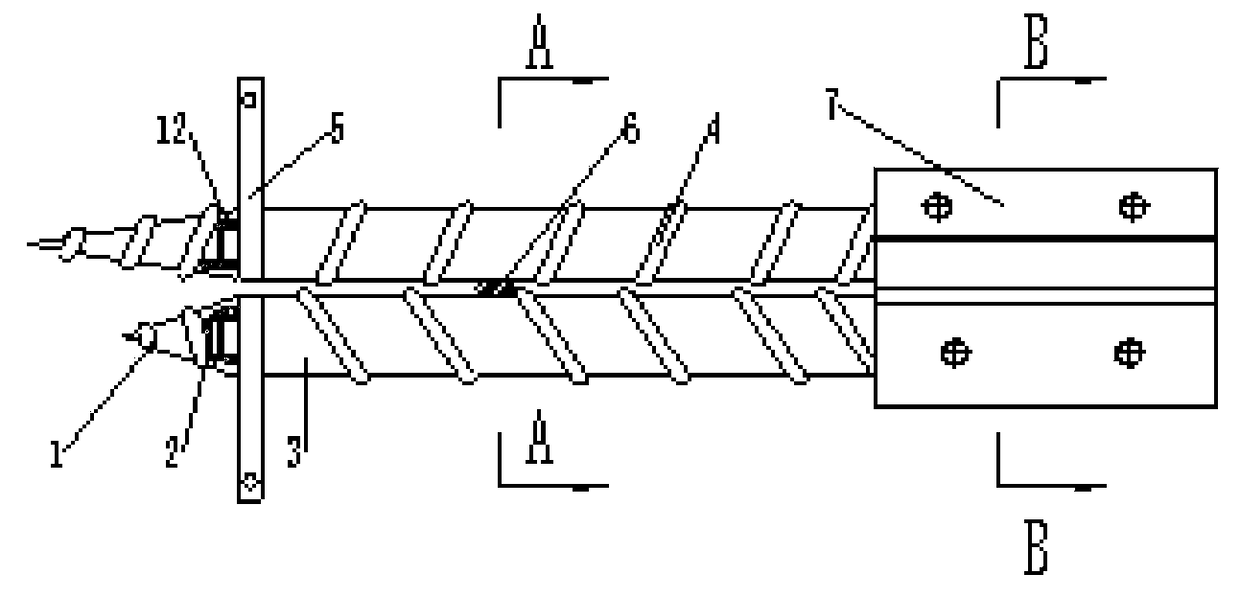

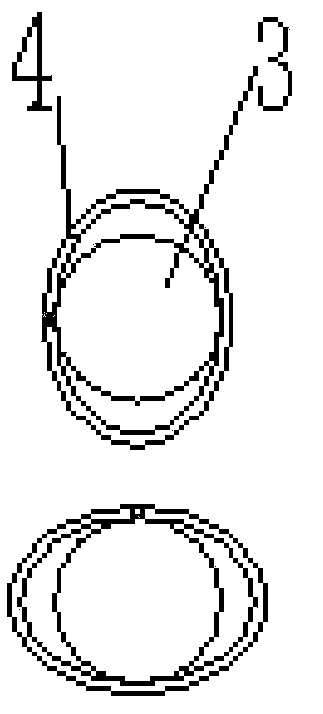

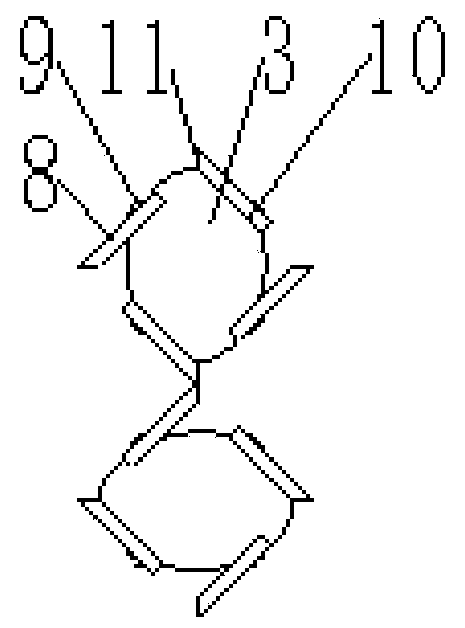

[0023] A vibration-exciting corn ear removal roller, comprising a long ear removal roller, a short ear removal roller 3, a guide cone 1, an adjustable bearing seat 5 and a strong pulling section 7, a long ear removal roller and a short ear removal roller 3 and a guide cone 1 is connected by the connecting shaft 2, the adjustable bearing seat 5 is set on the connecting shaft 2 and is close to the long ear picking roller and the short ear picking roller 3, and the strong pulling section 7 is installed on the long ear picking roller and the short ear picking roller 3 The rear end of the head, the long ear roller and the short ear roller 3 are welded with spiral ribs 4, the adjustable bearing seat 5 is located between the guide cone 1 and the ear roller 3 and is installed on the connecting shaft, through the adjustable bearing The change of seat 5 positions realizes the adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com