A Combined Ear Picking Roller for Corn Harvester

A corn harvester and ear picking roller technology, which is applied to harvesters, agricultural machinery and implements, and applications, can solve problems that affect harvesting speed, grain shedding, and blockage, so as to improve operating efficiency, reduce gnaw damage, and expand gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

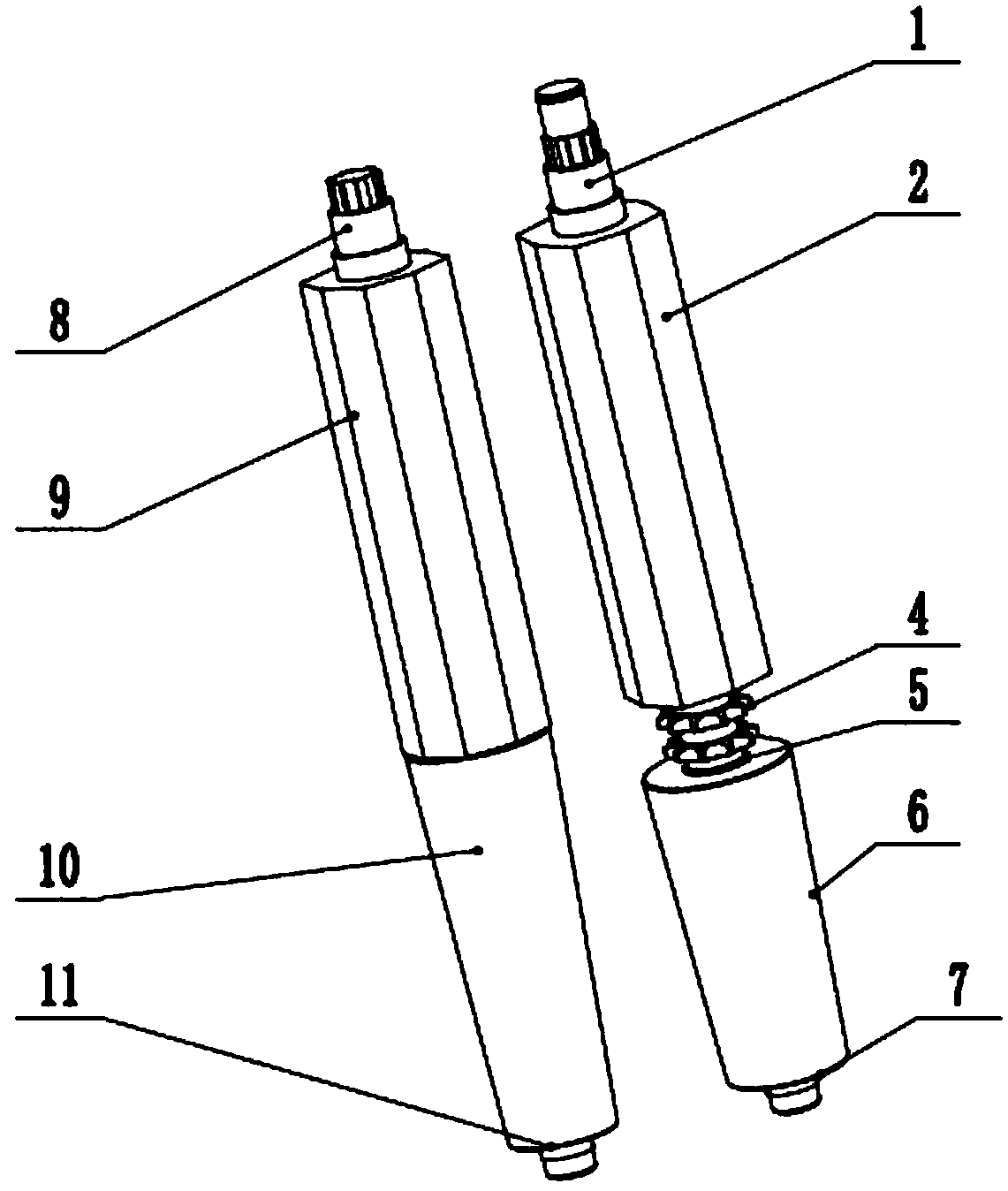

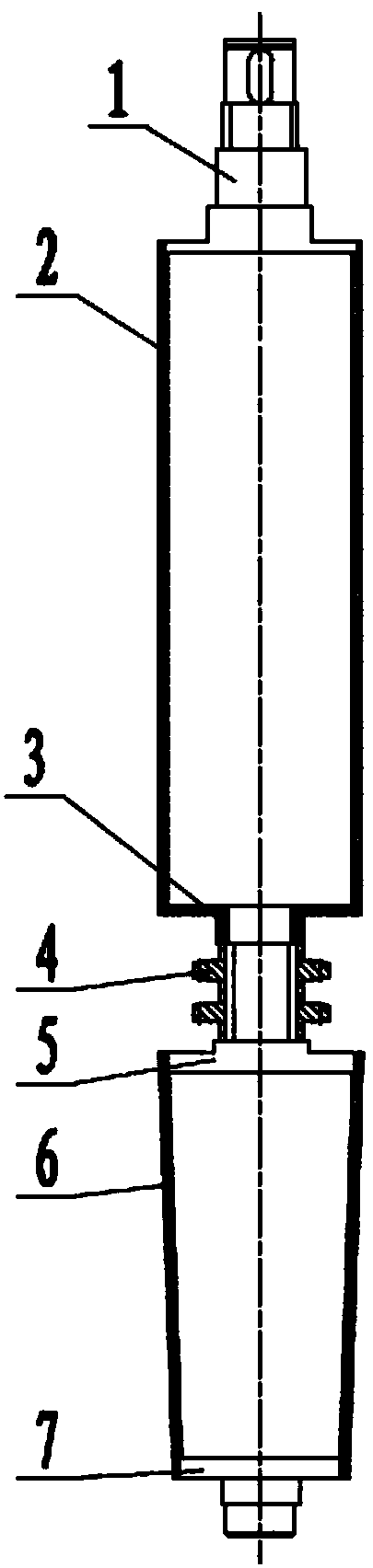

[0030] Such as figure 1 , figure 2 and image 3 , This embodiment makes a detailed description of the structure and principle of a combined corn harvester picking roller of the present invention.

[0031] The invention provides a combined ear picking roller for a corn harvester, comprising an A-type roller and a B-type roller;

[0032] Described A-type roller comprises main roller upper spindle head 1, main fringe picking roller 2, main roller lower spindle head 3, sprocket wheel 4, auxiliary roller upper spindle head 5, main stem pulling roller 6 and auxiliary roller lower spindle head 7; The main roller upper spindle head 1 is inserted into the upper cavity of the main ear picking roller 2 and then welded together, and the main roller lower spindle head 3 is inserted into the lower cavity of the main ear picking roller 2. Welded together, the lower spindle head 3 of the main roller is a hollow thread structure, the upper spindle head 5 of the auxiliary roller is inserted...

Embodiment 2

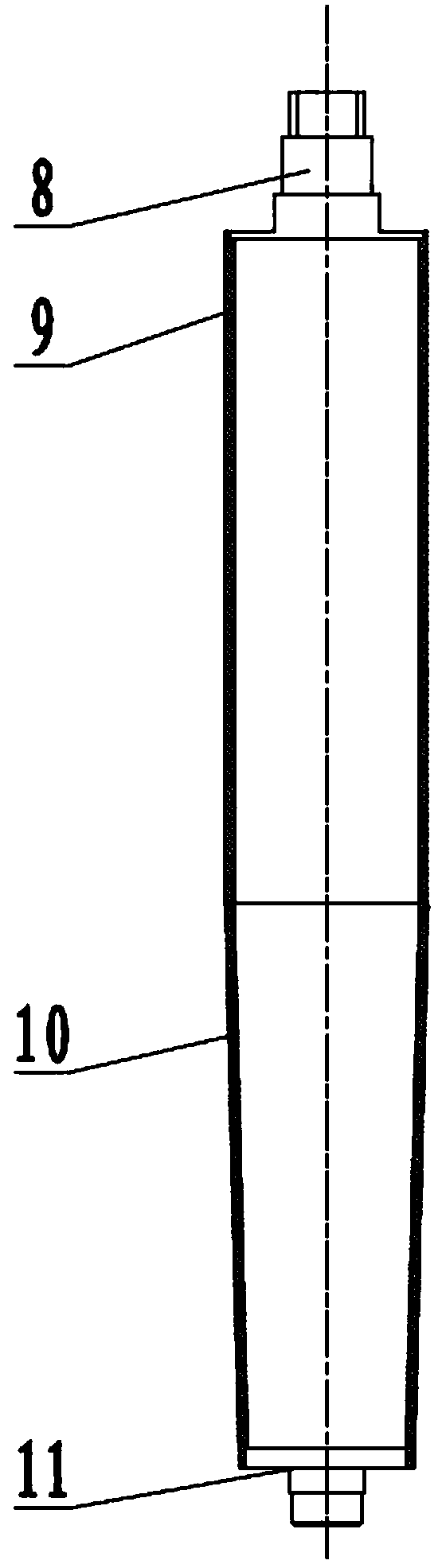

[0036] Such as Figure 4 , Figure 5 and Figure 6 As shown, this embodiment is an embodiment further improved on the basis of Embodiment 1, and at the same time, a further detailed description of the present invention is made.

[0037] The structure of the main plucking ear roller 2 on the top of the A-type roller and the passive plucking ear roller 9 on the top of the B-type roller is a special-shaped polygonal column structure, and the number of edges of the special-shaped multi-edge structure is an even number, and the central angle of the cross section remains No change, the internal angle is adjusted to be one large and one small adjacent two angles, one of the internal angles is adjusted to α+Δ, and the other is adjusted to α-Δ, the Δ≤180 / n, the cross-section of the special-shaped polygonal roller The side is tangent to the circumscribed circle of the regular polygon, and n is the number of edges of the special-shaped polygonal prism; with the special-shaped polygonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com