Automatic-grading quartz sand grinding machine and working method thereof

A technology of automatic grading and working methods, applied in chemical instruments and methods, cleaning methods and utensils, solid separation, etc., to achieve the effect of increasing output, improving quality, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

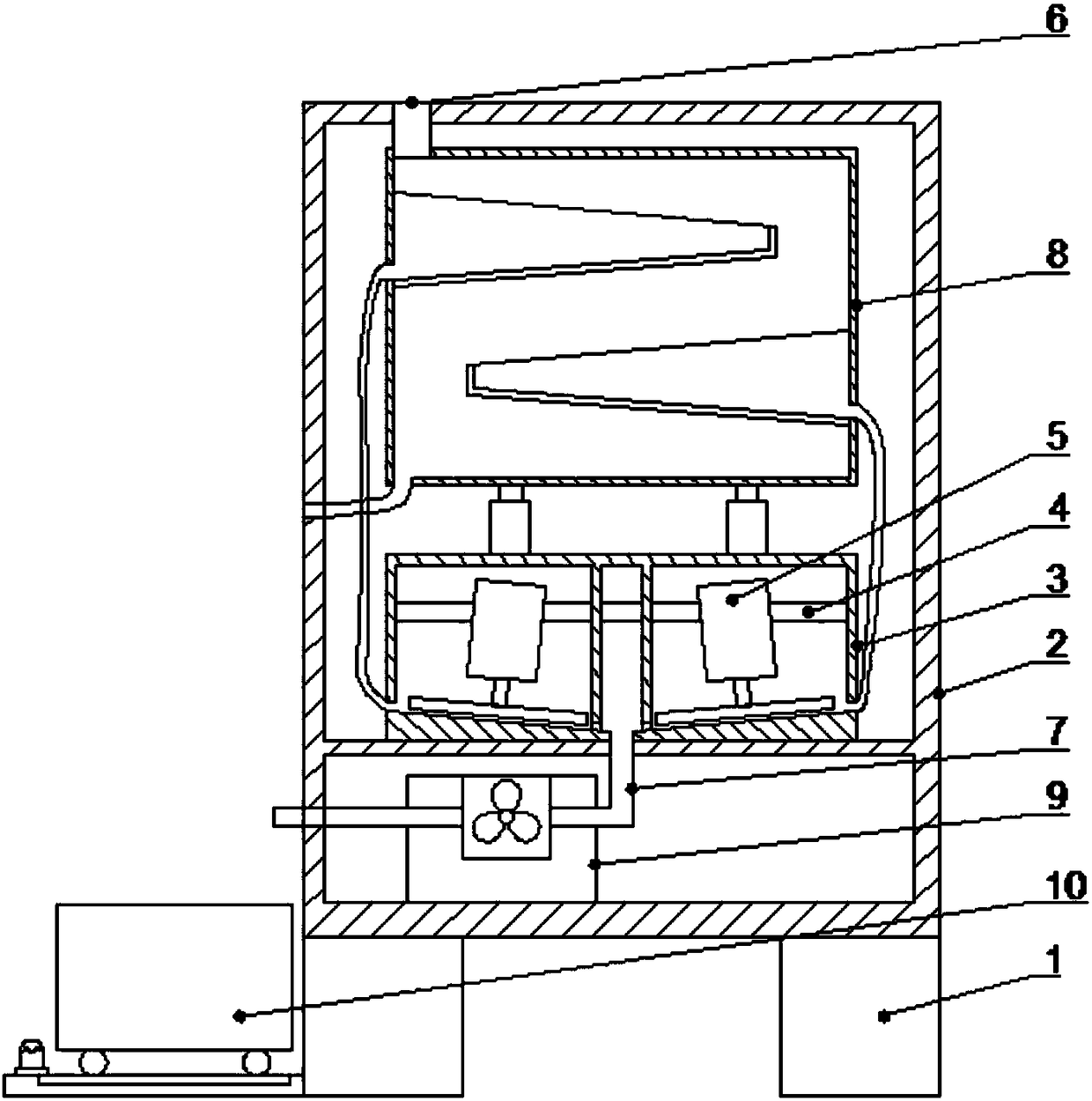

[0035] Such as figure 1 The shown automatic grading quartz sand grinder includes: a base 1, a shell 2, an inner container 3, a support 4, a grinding disc 5, a feed port 6, a discharge port 7 and a sorting mechanism 8. The base 1 An outer shell 2 is arranged on the outer shell 2, an inner tank 3 is arranged inside the inner tank 3, a bracket 4 is arranged on the inner surface of the inner tank 3, a grinding disc 5 is arranged on the bracket 4, and the bracket 5 is fixed on the inner tank 3 Above, a discharge port 7 is provided below the inner tank 3; a feed port 6 is provided at the upper end of the casing 2, and a sorting mechanism 8 is provided below the feed port 6, and the sorting mechanism 8 is arranged inside Above the liner 3, the sorting mechanism 8 is connected with the liner 3.

[0036] The sorting mechanism 8 described in this embodiment includes a box body 81, an oscillator 82, a filter screen 83 and a sand collection tank 84, the box body 81 is arranged inside the...

Embodiment 2

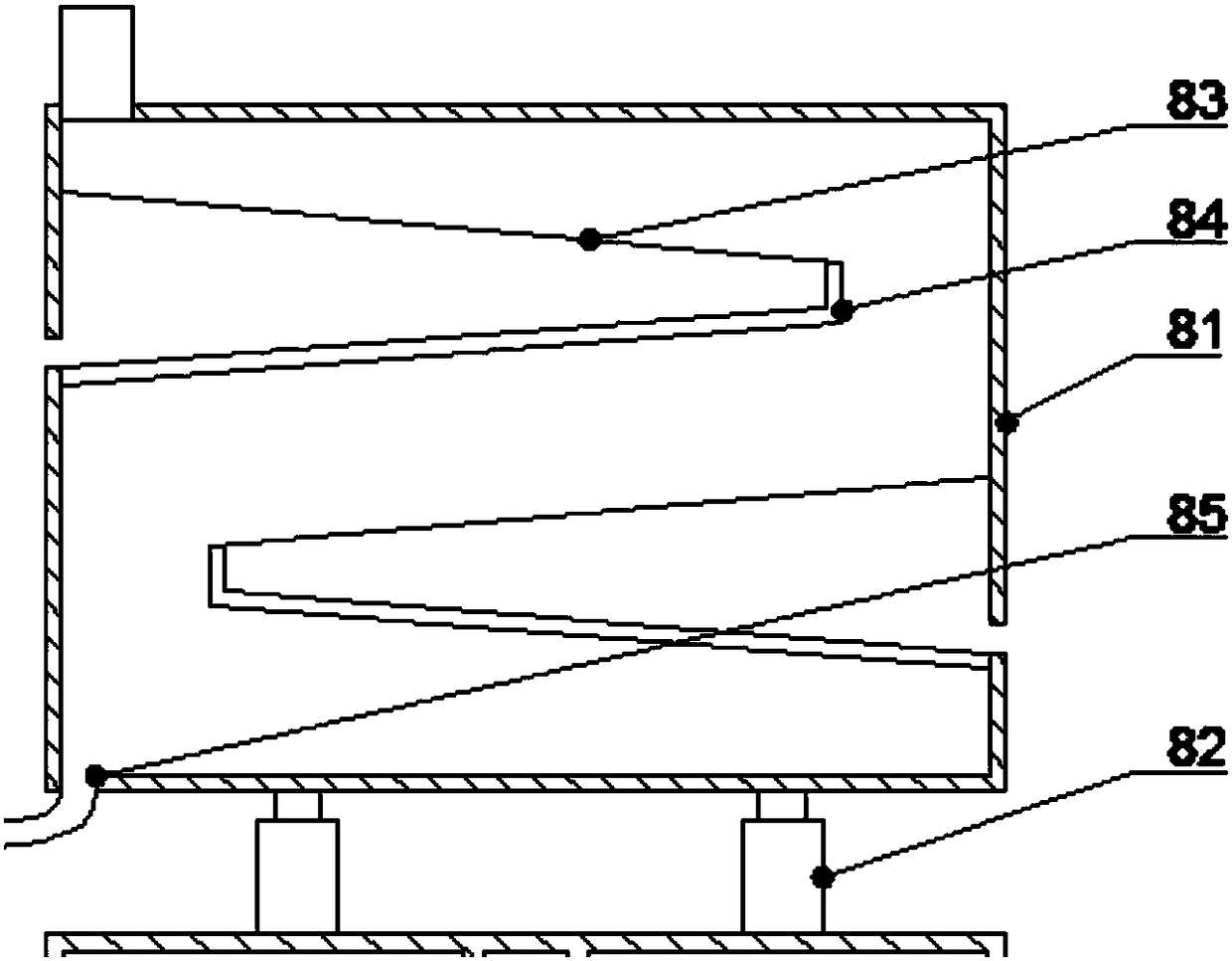

[0045] Such as figure 2 The shown automatic grading quartz sand grinder includes: a base 1, a shell 2, an inner container 3, a support 4, a grinding disc 5, a feed port 6, a discharge port 7 and a sorting mechanism 8. The base 1 An outer shell 2 is arranged on the outer shell 2, an inner tank 3 is arranged inside the inner tank 3, a bracket 4 is arranged on the inner surface of the inner tank 3, a grinding disc 5 is arranged on the bracket 4, and the bracket 5 is fixed on the inner tank 3 Above, a discharge port 7 is provided below the inner tank 3; a feed port 6 is provided at the upper end of the casing 2, and a sorting mechanism 8 is provided below the feed port 6, and the sorting mechanism 8 is arranged inside Above the liner 3, the sorting mechanism 8 is connected with the liner 3.

[0046] The sorting mechanism 8 described in this embodiment includes a box body 81, an oscillator 82, a filter screen 83 and a sand collection tank 84, the box body 81 is arranged inside th...

Embodiment 3

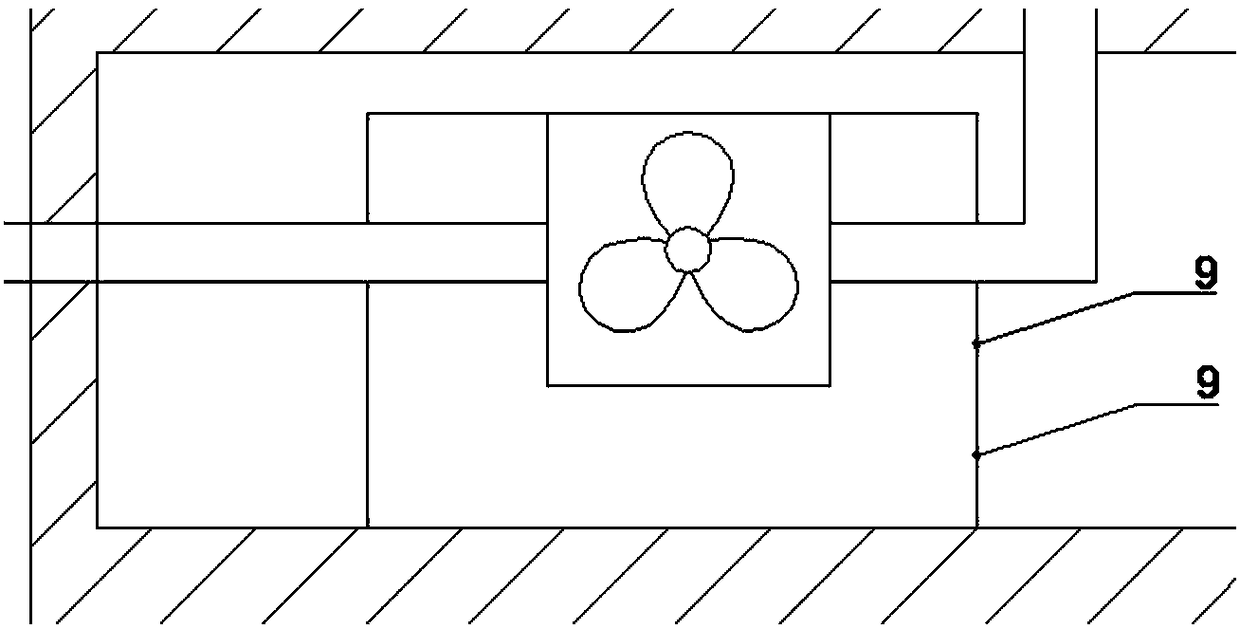

[0049] Such as image 3 The shown automatic grading quartz sand grinder includes: a base 1, a shell 2, an inner container 3, a support 4, a grinding disc 5, a feed port 6, a discharge port 7 and a sorting mechanism 8. The base 1 An outer shell 2 is arranged on the outer shell 2, an inner tank 3 is arranged inside the inner tank 3, a bracket 4 is arranged on the inner surface of the inner tank 3, a grinding disc 5 is arranged on the bracket 4, and the bracket 5 is fixed on the inner tank 3 Above, a discharge port 7 is provided below the inner tank 3; a feed port 6 is provided at the upper end of the casing 2, and a sorting mechanism 8 is provided below the feed port 6, and the sorting mechanism 8 is arranged inside Above the liner 3, the sorting mechanism 8 is connected with the liner 3.

[0050] The discharge port 7 described in this embodiment is provided with a dust removal mechanism 9, and the dust removal mechanism 9 includes a fan 91 and a dust storage box 92, the fan 91...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com