Conveying equipment capable of achieving goods delivery with freely-bent track

A technology of conveying equipment and curved tracks, applied in the directions of conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of the limitation of the length of the conveying equipment and the bending amplitude, the high motor power, and the easy failure of the chain, so as to overcome the bending Smaller amplitude, improved reliability, overcoming the effect of more prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

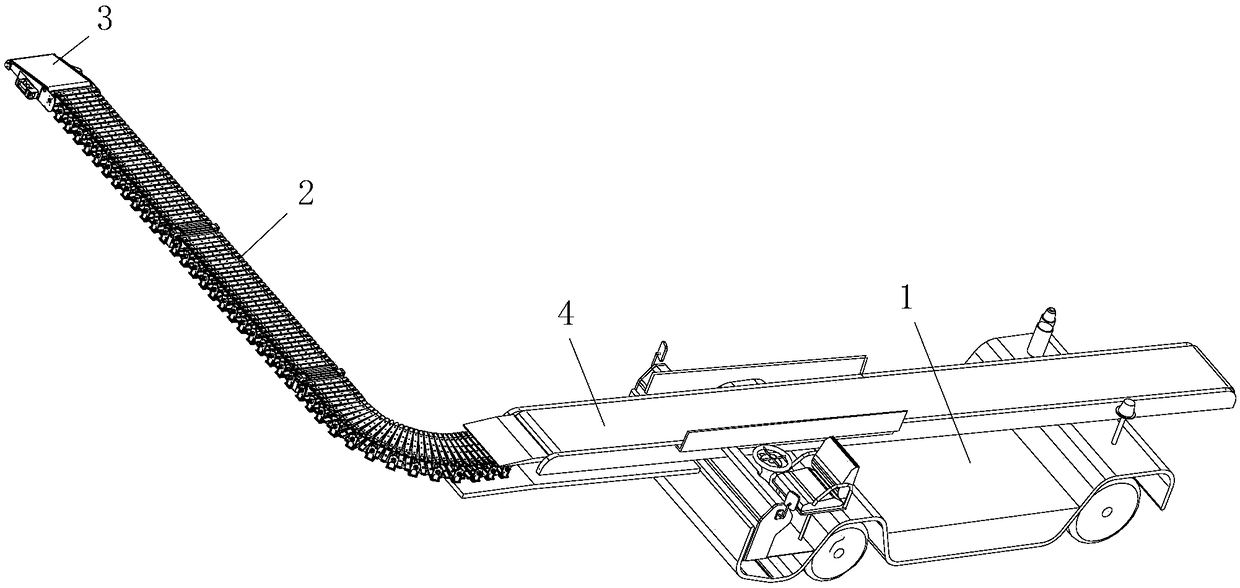

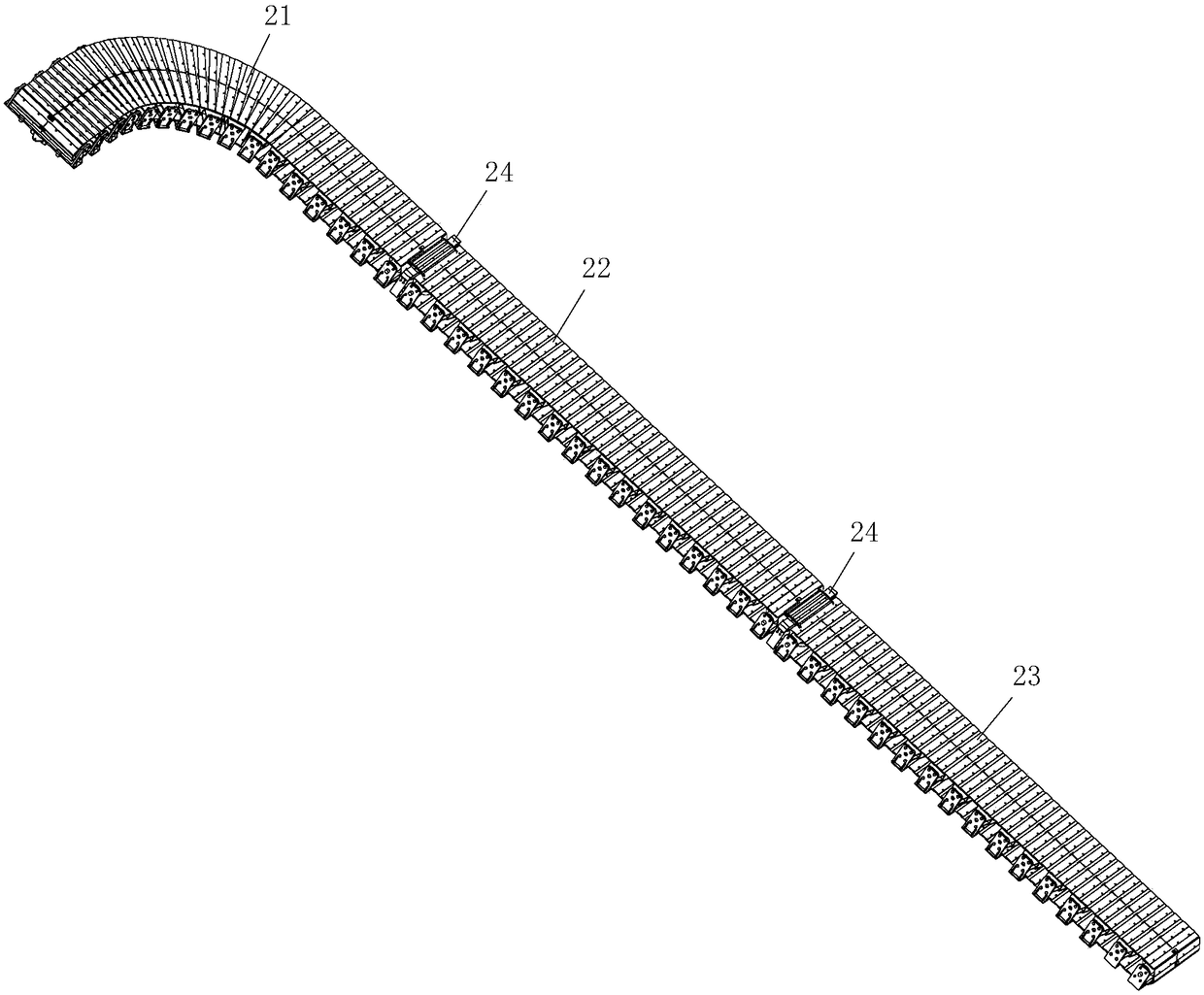

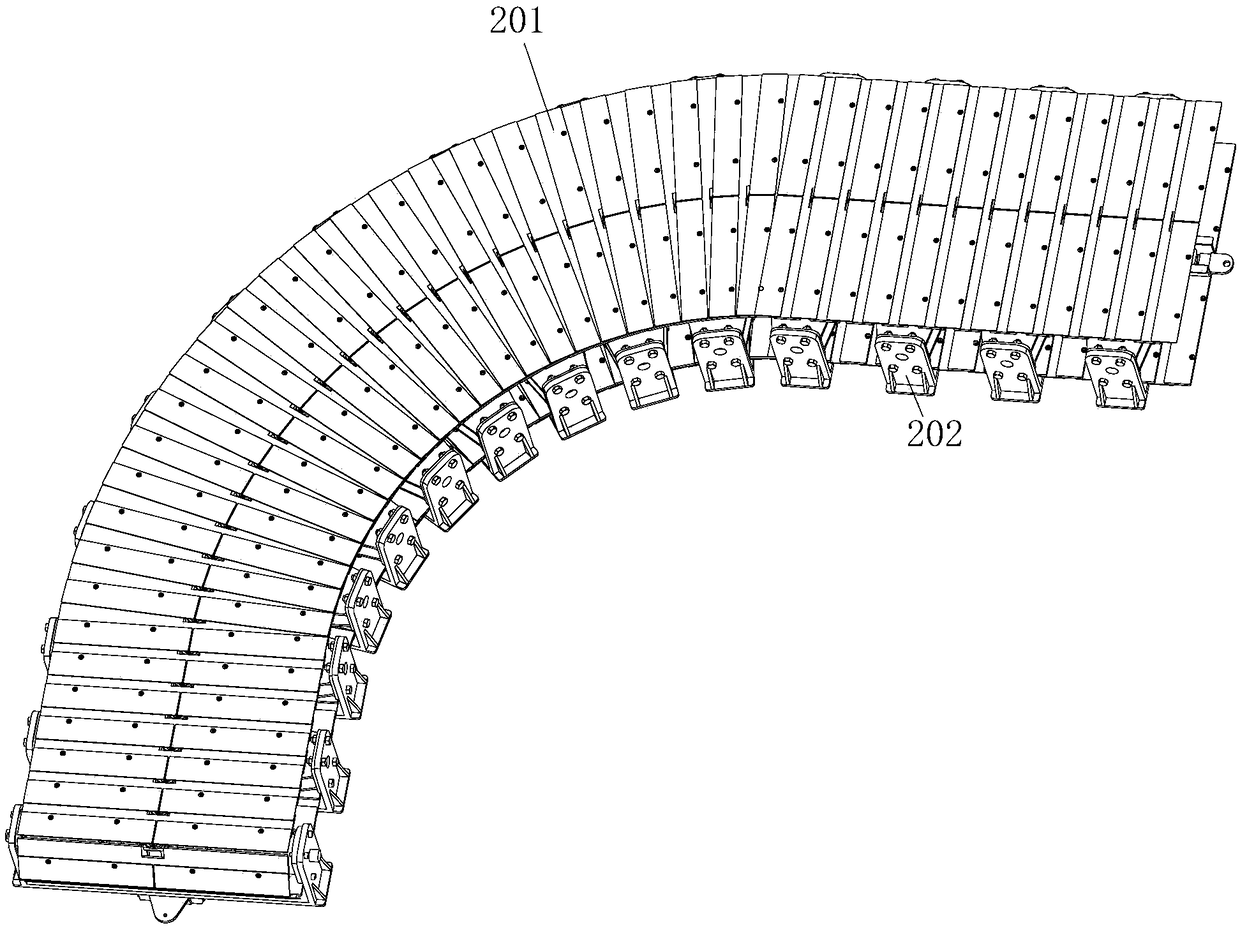

[0030] In this example, refer to image 3 , Figure 5 , Image 6 and Figure 7, the conveying equipment that can realize free curved track conveying goods includes at least one conveying section, and the conveying section includes a turnable chain-plate conveying mechanism 201 that operates in a cycle, and the bendable chain-plate conveying mechanism 201 is installed on the chassis mechanism 202, the bottom surface of the chassis mechanism 202 is equipped with a bottom wheel 208 that supports the entire turnable chain plate transmission mechanism 201 to move; the turnable chain plate transmission mechanism 201 includes a chain plate 203, a motor 206 and a drive wheel 207, several The chain plates 203 are connected in series to form a circular transmission structure with upper and lower layers (similar to the track structure). Motors 206 are arranged at both ends of the chain plate circular transmission structure. The motor 206 is connected to the driving wheel 207, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com