Washing machine

A washing machine and inner tub technology, applied in the field of washing machines, can solve the problems of small structure space, inability to achieve cleaning purpose, dirt and other problems, and achieve the effect of eliminating long-term accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

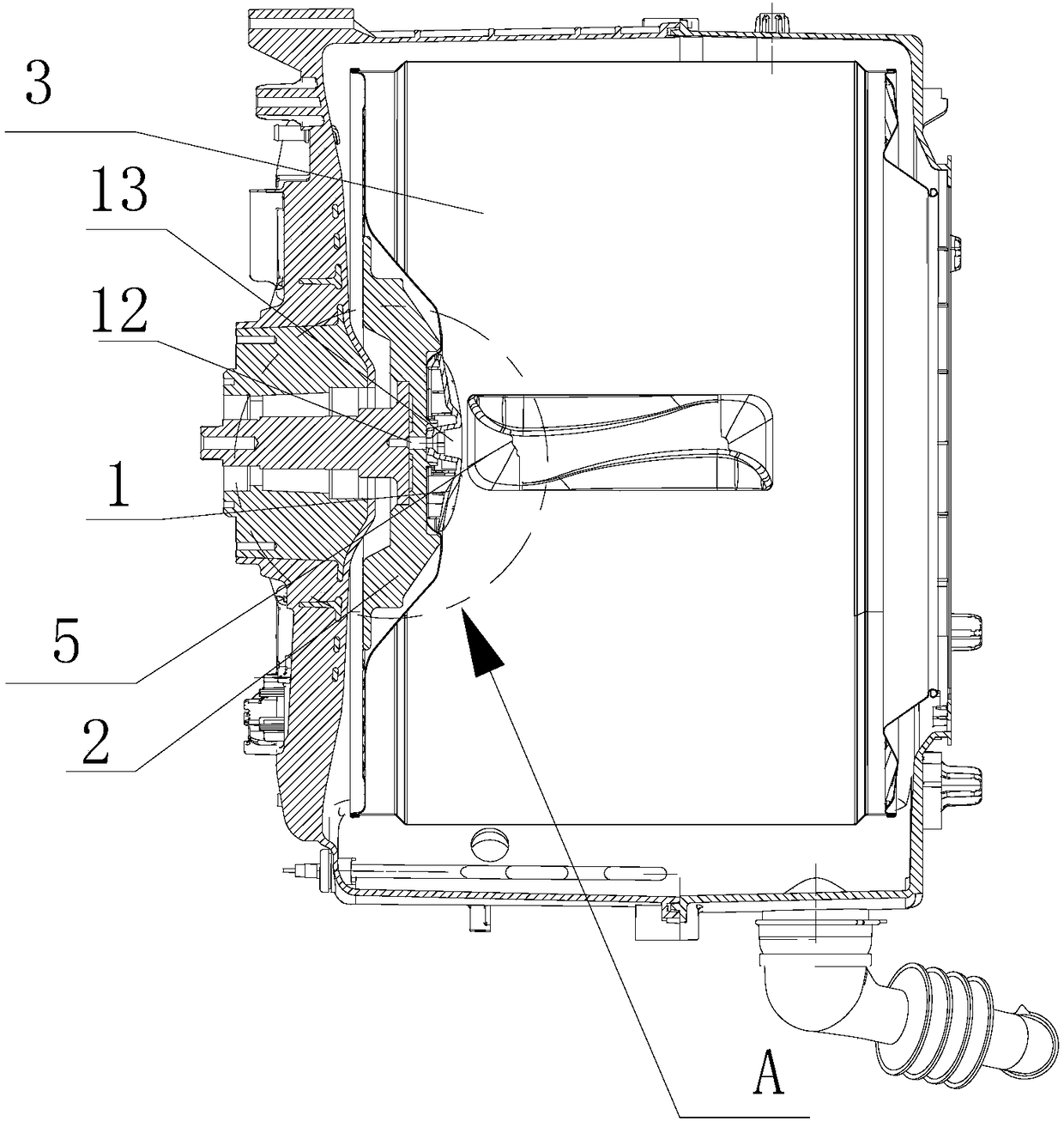

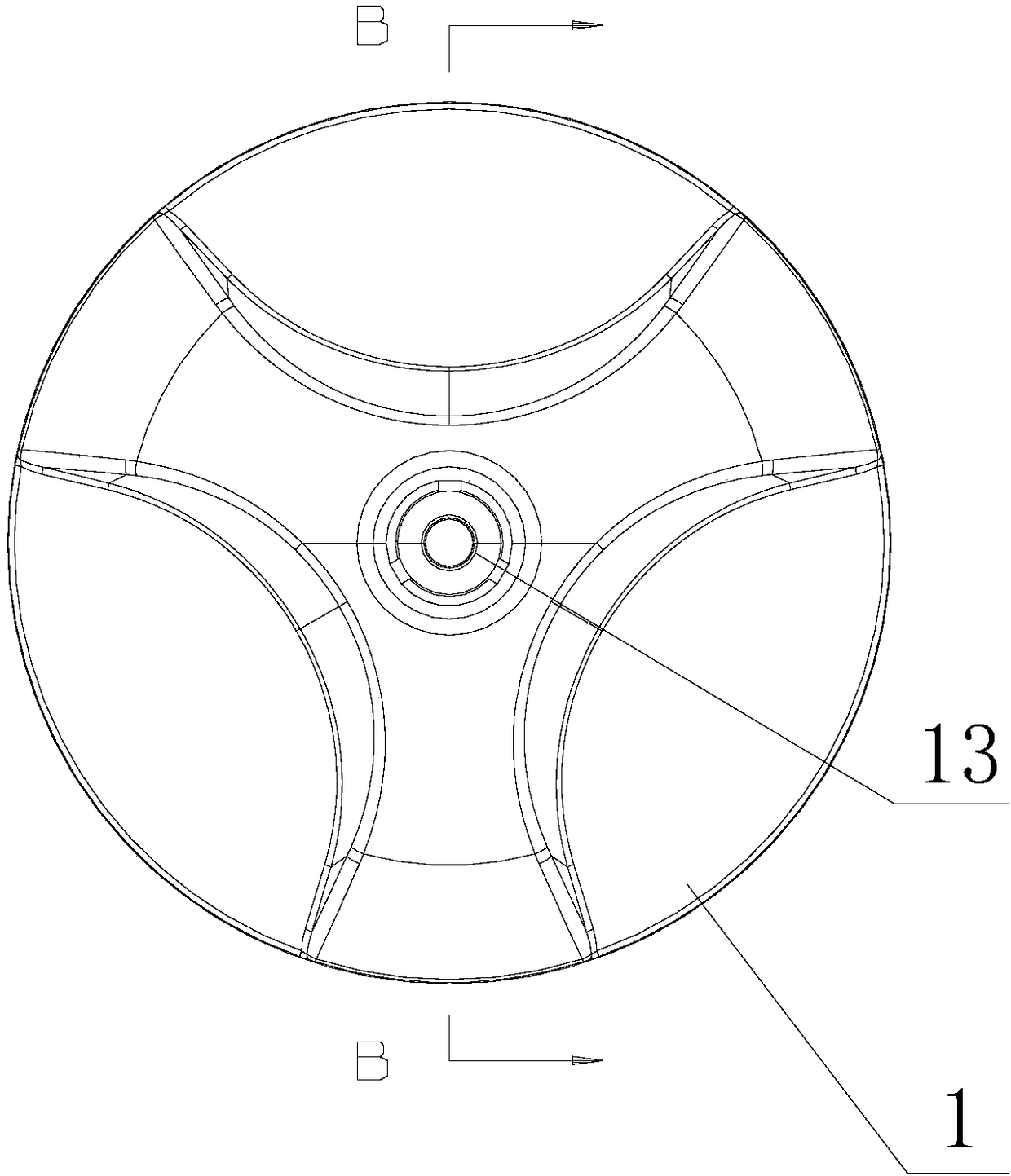

[0048] see Figure 1 to Figure 5 As shown, this embodiment provides a drum washing machine, which includes an inner drum 3, and an inner drum bottom cover 1 is installed on the bottom of the inner drum 3, wherein the inner drum bottom cover 1 is sealingly connected with the surface of the inner drum to form a sealed space.

[0049] In the prior art, when washing water enters the chamber between the bottom cover 1 of the inner cylinder and the bottom of the inner cylinder, it is difficult to remove the washing water. The existing cleaning methods for the inner cylinder include rinsing with water, scrubbing with a brush, Cleaning particles and other solutions are used, but because of the narrow structural space, the above cleaning methods of the inner cylinder cannot achieve the purpose of cleaning. Then, during the laundry process, the washing water will accumulate in the bottom cover of the inner tube for a long time, causing the problem of bacteria breeding and contamination....

Embodiment 2

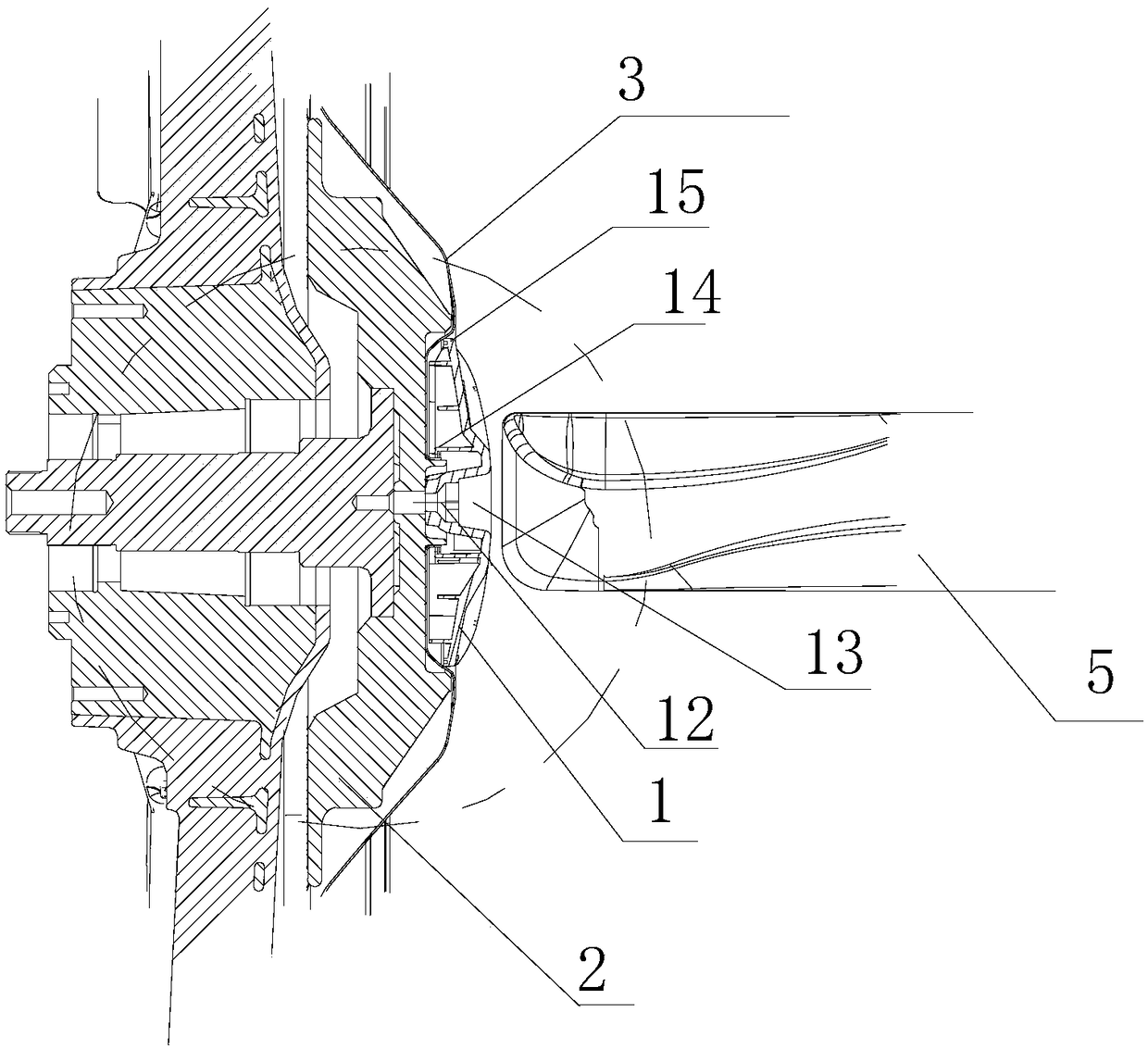

[0053] see Figure 1-Figure 5 As shown, in this embodiment, the bottom cover 1 of the inner cylinder of the washing machine is a disc-shaped structure, which is fastened to the bottom of the inner cylinder and fixed to the bottom of the inner cylinder by screws 12, because the bottom cover 1 of the inner cylinder is passed through The screw is fixed to the bottom of the inner cylinder, so the washing water may also enter the cavity formed between the bottom cover 1 of the inner cylinder and the bottom of the inner cylinder along the screw 12. Therefore, in this embodiment, the bottom cover of the inner cylinder needs to be carried out in two places. Sealing, the first sealing part is on the outer circumference of the inner cylinder bottom cover 1, and the second sealing part is at the screw hole in the center of the inner cylinder bottom cover. Wherein, preferably, the circumferential surface of the bottom cover of the inner cylinder and the screw holes thereof are sealed and ...

Embodiment 3

[0058] see Figure 1-Figure 5 As shown, in the embodiment, the inner tube bottom cover 1 of the washing machine in this embodiment is provided with a structure for fixing the sealing ring, specifically, the end face of the outermost circular rib 15 and the innermost circular rib 14 grooves 4 are respectively arranged on the inner surface of the end, and the sealing ring is accommodated in the groove 4 and protrudes out of the groove to make sealing contact with the surface of the inner cylinder;

[0059] Further preferably, at least one ring of grooves is respectively provided on the end surface of the outermost circular rib 15 and the inner surface of the end of the innermost ring rib 14, and each ring of groove is correspondingly provided with a sealing ring;

[0060] In order to further improve the sealing effect of the sealing ring, the sealing ring in the present invention can be designed in a variety of ways, and the groove 4 can also be diversified accordingly. More pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com