fuel rod storage

A fuel rod storage and storage technology, applied in the field of fuel rod storage, can solve problems such as welding seam damage, and achieve the effects of high functional reliability and low maintenance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

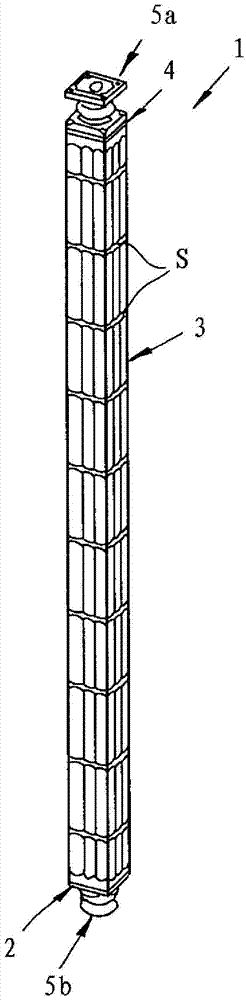

[0033] exist figure 1 A fuel rod storage 1 is shown in , which has a storage bottom 2 , a storage shell 3 and a storage cover 4 . Preferably and according to the described exemplary embodiment, the fuel rod store 1 is designed as a cuboid. The storage shell 3 has webs S which, according to the described exemplary embodiment, serve as support surfaces when storing and / or transporting the fuel rod storage. according to figure 1 , Install the buffer 5a on the reservoir cover 4. A buffer 5b is mounted on the bottom side or towards the container bottom 2, so that preferably and according to the described embodiment the length of the fuel rod container 1 including the buffers 5a, 5b is equal to the length of the fuel elements.

[0034] exist figure 1 Not shown, the support surface of the storage bottom side of the buffer 5b has drainage grooves through which water can be conducted when the buffer-protected fuel rod storage 1 is removed from the storage tank.

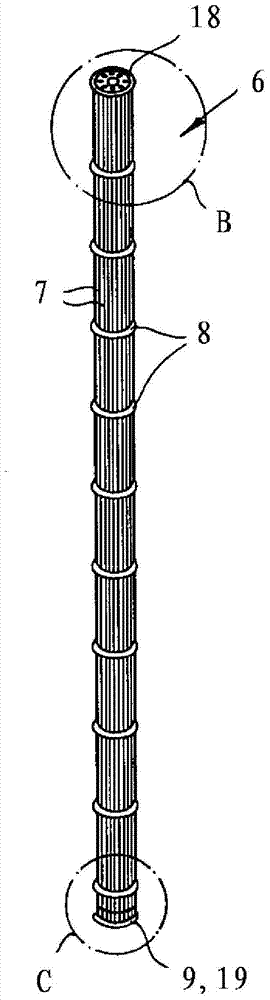

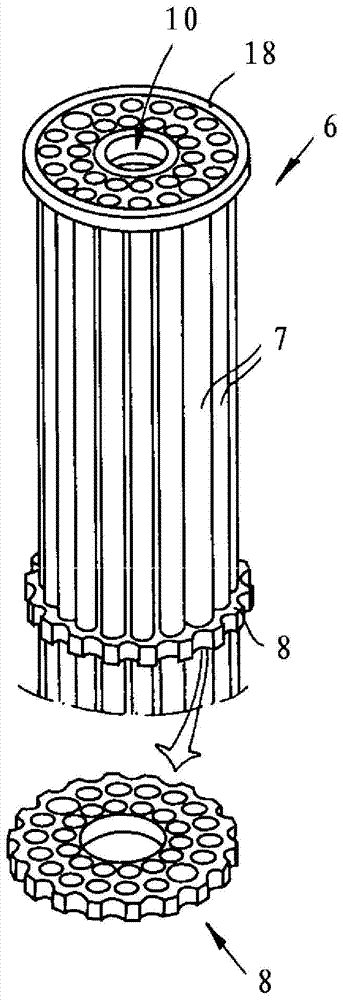

[0035] In Fig. 2a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com