Intelligent control safety check equipment

A security inspection and intelligent control technology, applied in the field of security inspection, can solve the problems of wasting energy, unable to increase speed, stampede accidents, etc., to achieve the effect of improving image resolution, avoiding overlapping occlusion, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings.

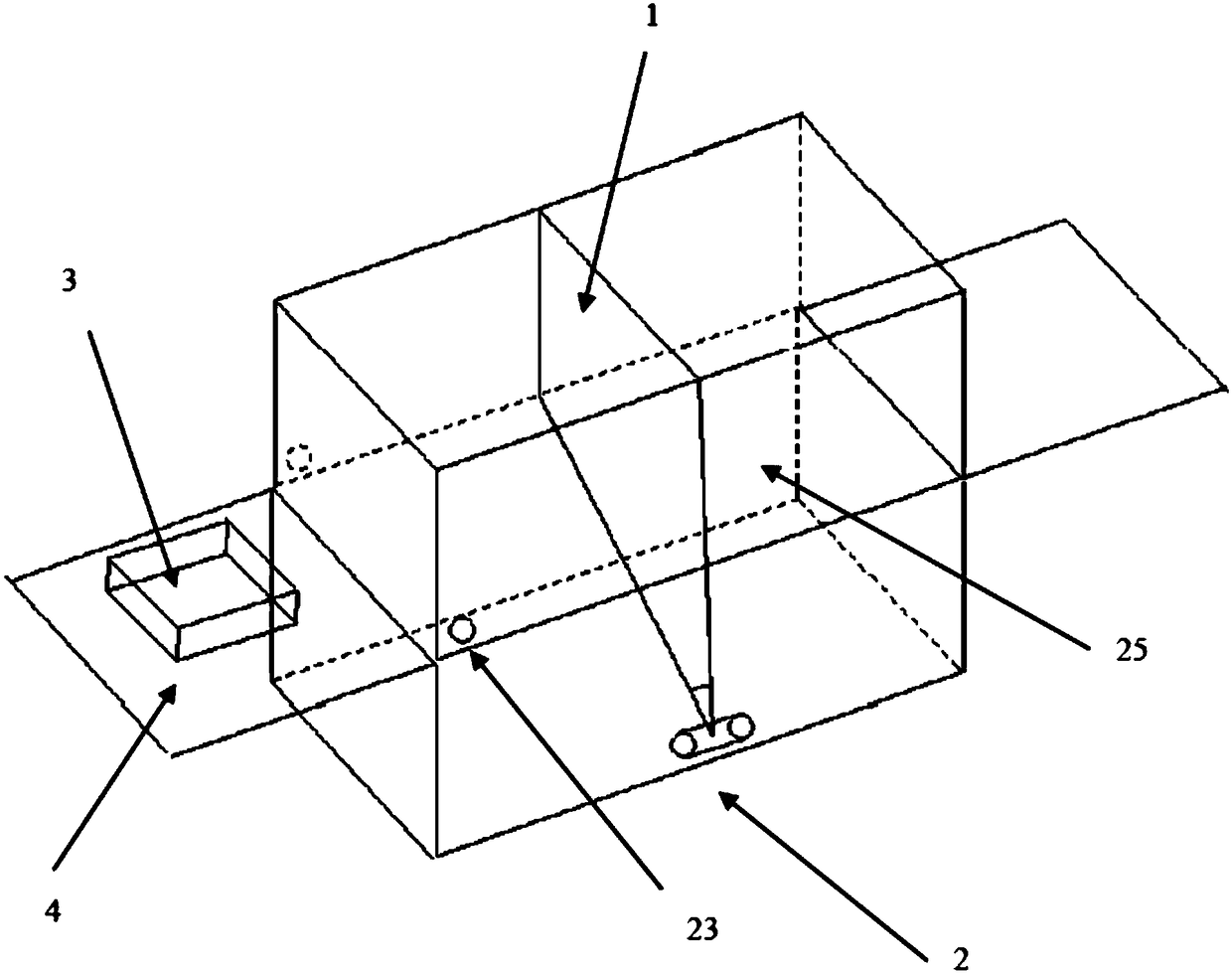

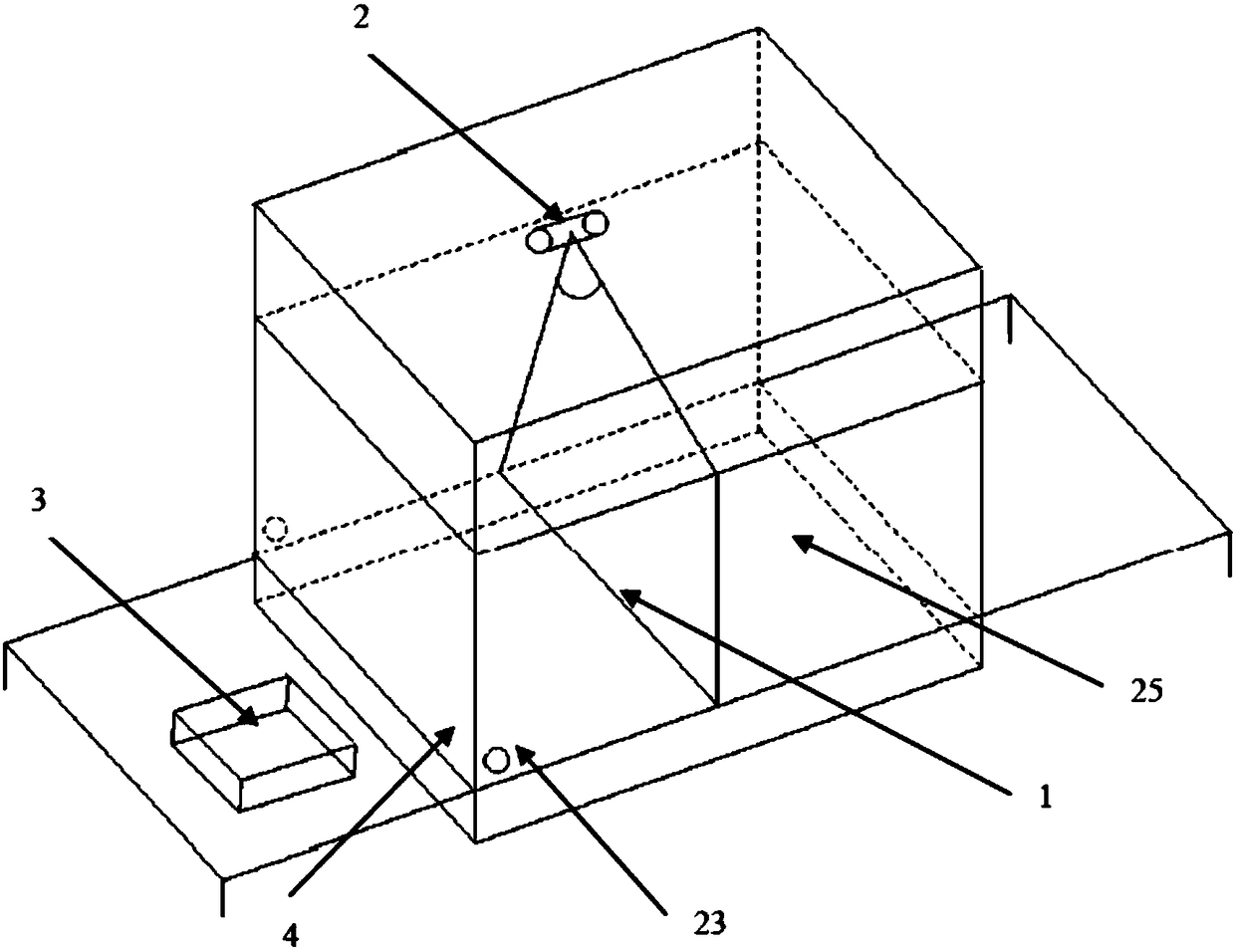

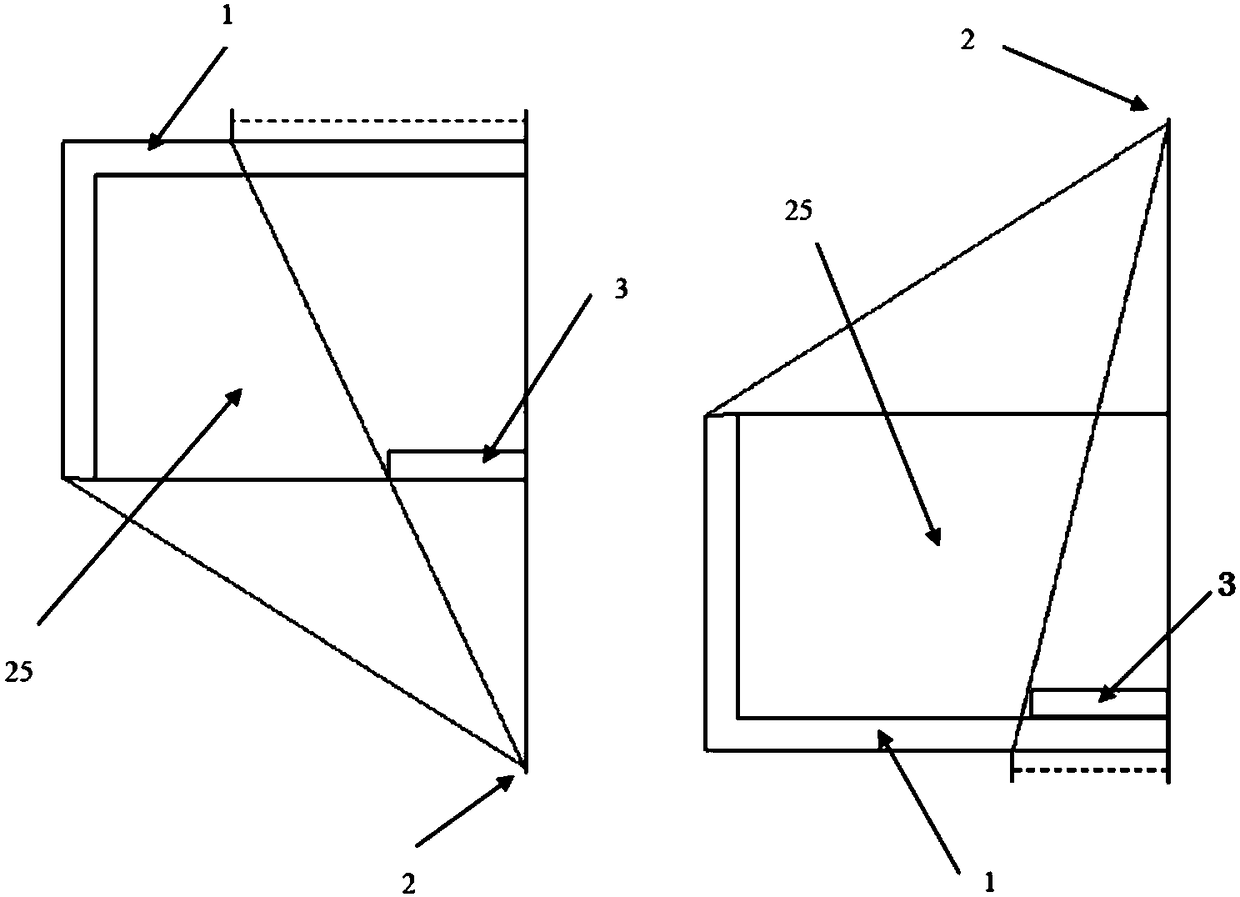

[0030] figure 1 It is a schematic diagram of the structure of the bottom-illuminated security inspection equipment, figure 2 It is a schematic diagram of the structure of the top-illuminated security inspection equipment, image 3 It is a structural comparison diagram of bottom-illuminated security inspection equipment and top-illuminated security inspection equipment. Such as image 3 As shown, the dotted line part shows the package of the same size. Under different illumination methods, the size of the image is larger, and the resolution of the larger image is higher, and the image is clearer. The safety inspection device of the present invention adopts the bottom-illuminated type, fully utilizes its geometric magnification feature, improves image resolution, and does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com