Method for detecting uniformity of ArF excimer laser light intensity by adopting probe step scanning

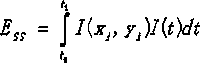

A step-scanning and uniformity technology, which is used in the field of ArF excimer laser light intensity uniformity detection with probe step-scanning, which can solve the problem of unstable laser output frequency single pulse, interference with light intensity uniformity distribution, and laser pulse time. Non-uniformity and other problems, to achieve the effect of eliminating the influence of time non-uniformity, strong anti-interference ability, and high-reliability synchronous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and embodiments.

[0024] The invention is mainly used for high-precision detection of the uniform distribution of laser light intensity output by the lighting system of the optical projection exposure lithography system, and provides feedback and reference for the optical design and correction of the lighting system. figure 1 Is the schematic diagram of excimer laser projection lithography illumination system. It can be seen from the figure that the illumination system of optical projection exposure lithography is a complex optical system, which consists of light source, transmission optical path, beam drift correction, beam expansion and shaping, energy detection and dose control, illumination homogenizer, mask light columns etc. The main function is to realize laser beam expansion, high-uniform high-intensity illumination, change partial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com