OLED functional layer ink jet printing preparation method and mask plate thereof

A technology of inkjet printing and mask plate, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as cumbersome process and quality influence of pixel electrodes, and achieve the effect of improving quality and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. protection scope of the invention.

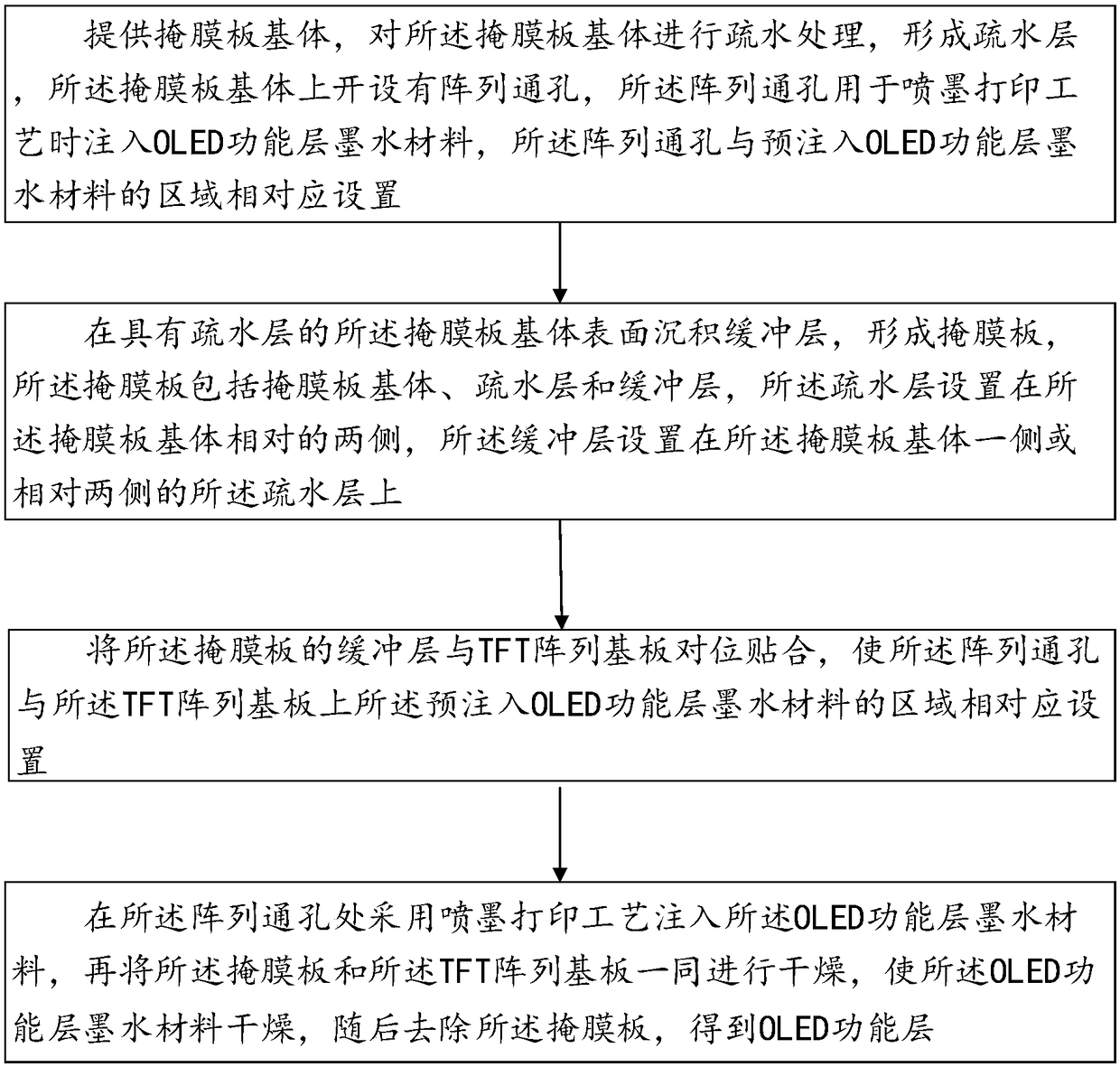

[0026] see Figure 1-Figure 3 , the first aspect of the present invention provides an OLED functional layer inkjet printing preparation method, comprising the following steps:

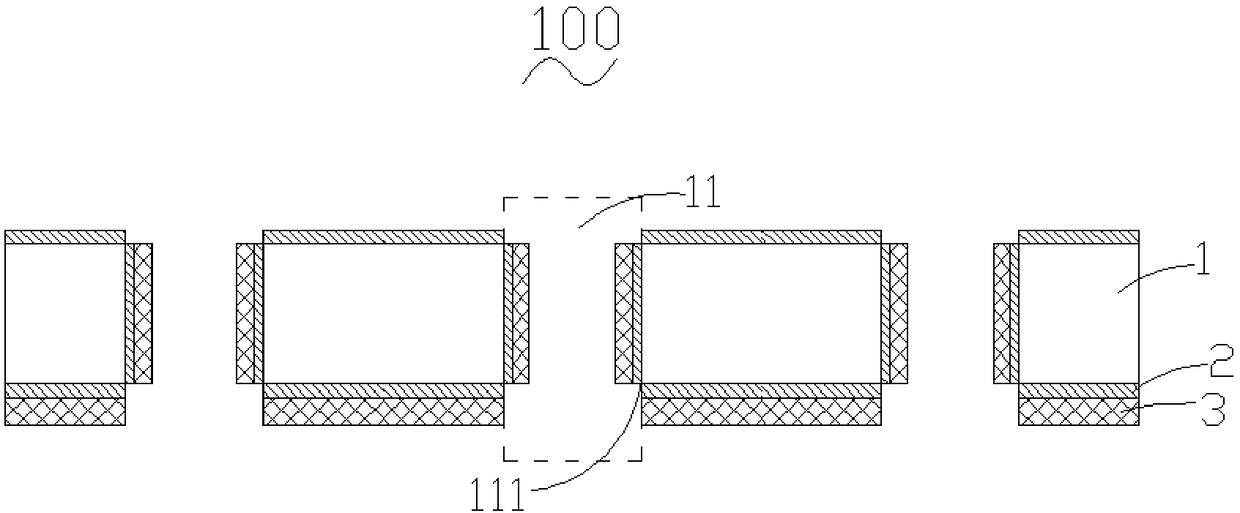

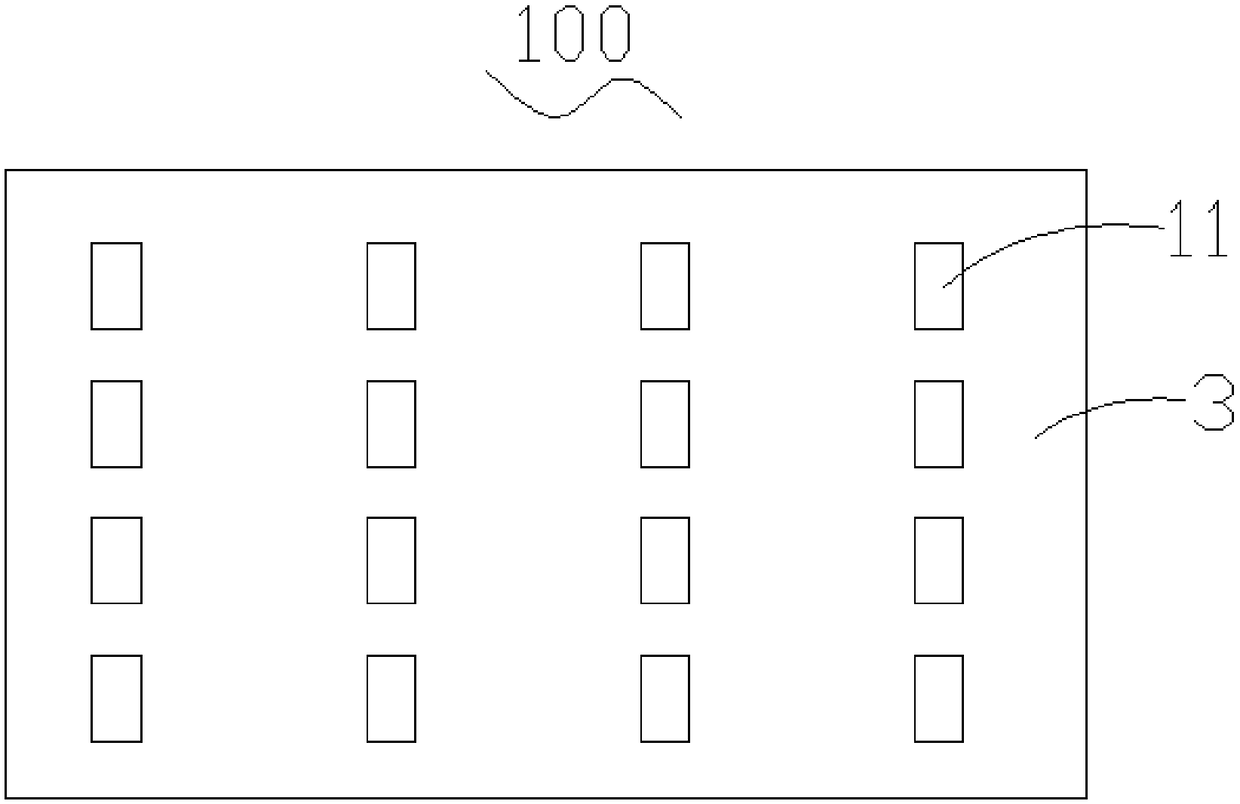

[0027] Step 1: Provide a mask base 1, perform hydrophobic treatment on the mask base 1 to form a hydrophobic layer 2, the mask base 1 is provided with an array of through holes 11, and the array through holes 11 are used for The OLED functional layer ink material is injected during the inkjet printing process, and the array through hole 11 is set corresponding to the area where the OLED functional layer ink material is pre-injected; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com