Adjustable damping system for sliding rail

A damping adjustment and damping technology, which is applied to furniture parts, household appliances, drawers, etc., can solve the problems of low practicability, inability to adjust tension spring tension, and inability to apply drawer slide rails of various specifications, so as to increase or decrease The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

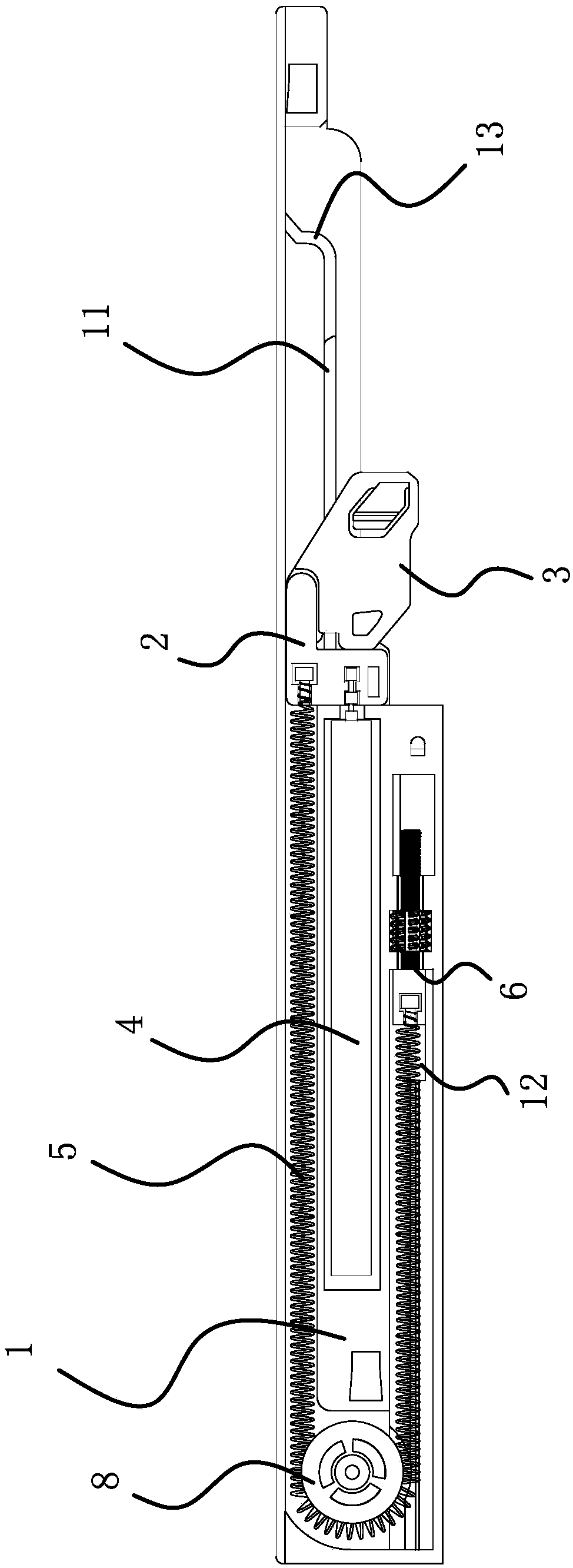

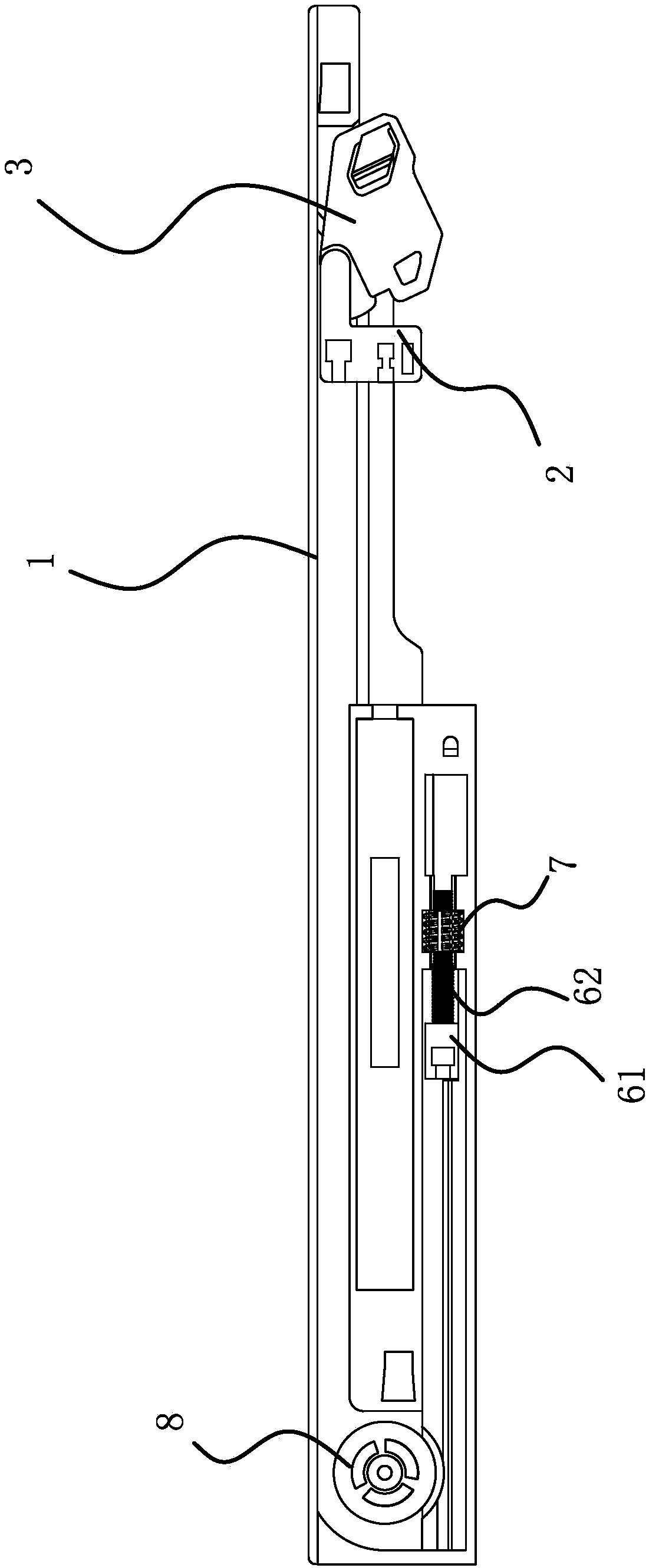

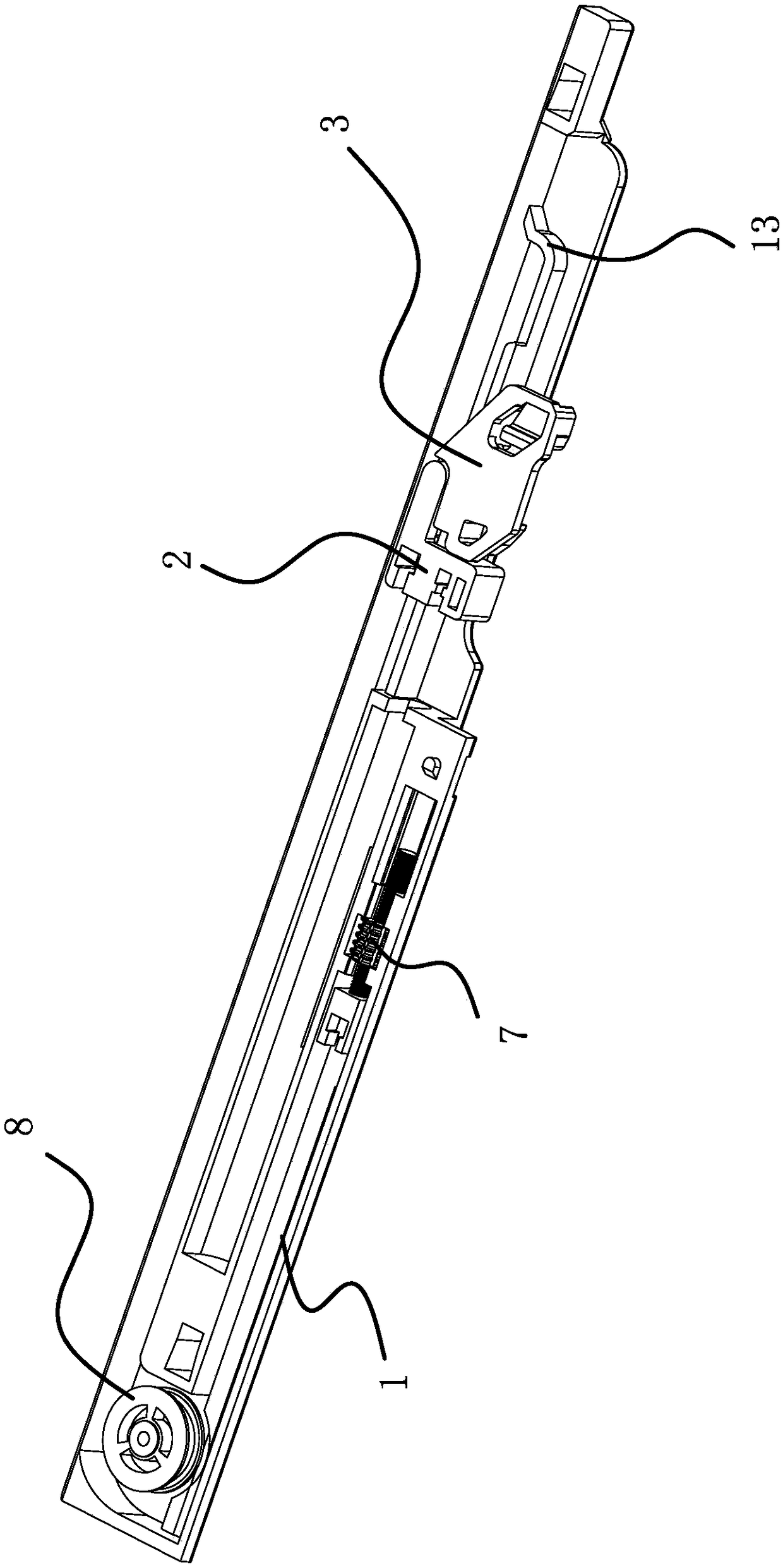

[0023] Such as figure 1 , figure 2 , image 3 As shown, the adjustable damping system of this slide rail includes a damping housing 1, a slider 2, a rotating pull block 3, a buffer cylinder 4, a tension spring 5, an adjustable tension spring 5 to adjust the tension of the slider 2, an adjustment member 6, and The nut 7, the guide wheel 8, and the buffer cylinder 4 are embedded in the damping shell 1, and the axle of the guide wheel 8 is rotatably connected to the upper end of the damping shell 1, and the lower end of the damping shell 1 has a guide bar 11, a slider 2 , The rotating pull block 3 is embedded on the guide slide 11 and slides along the guide slide 11, the rotate pull block 3 is rotatably connected to the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com