Oil pressure control system

A technology of oil pressure control and oil pump, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., and can solve the problems of inability to smoothly control the oil pressure actuator and low precision of oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

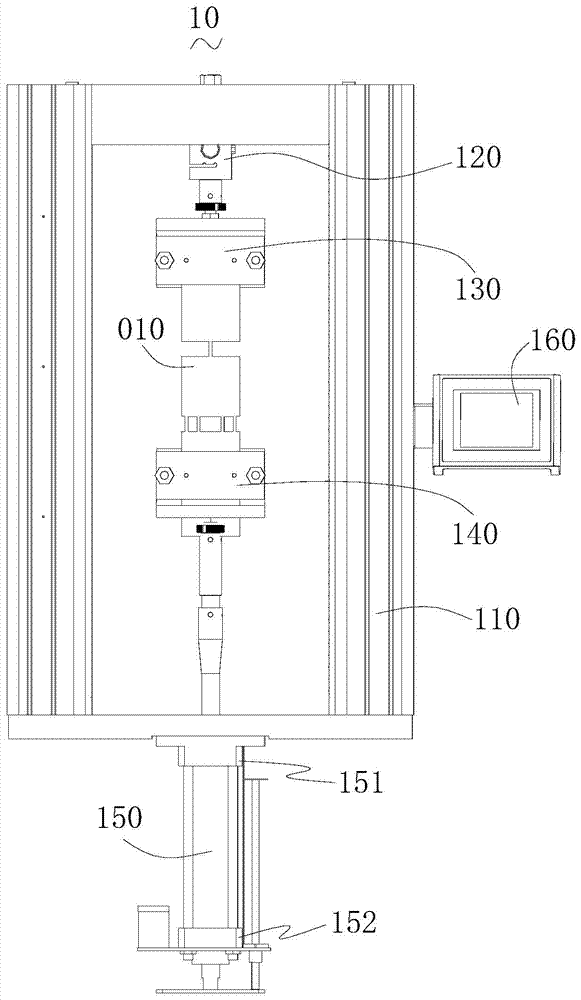

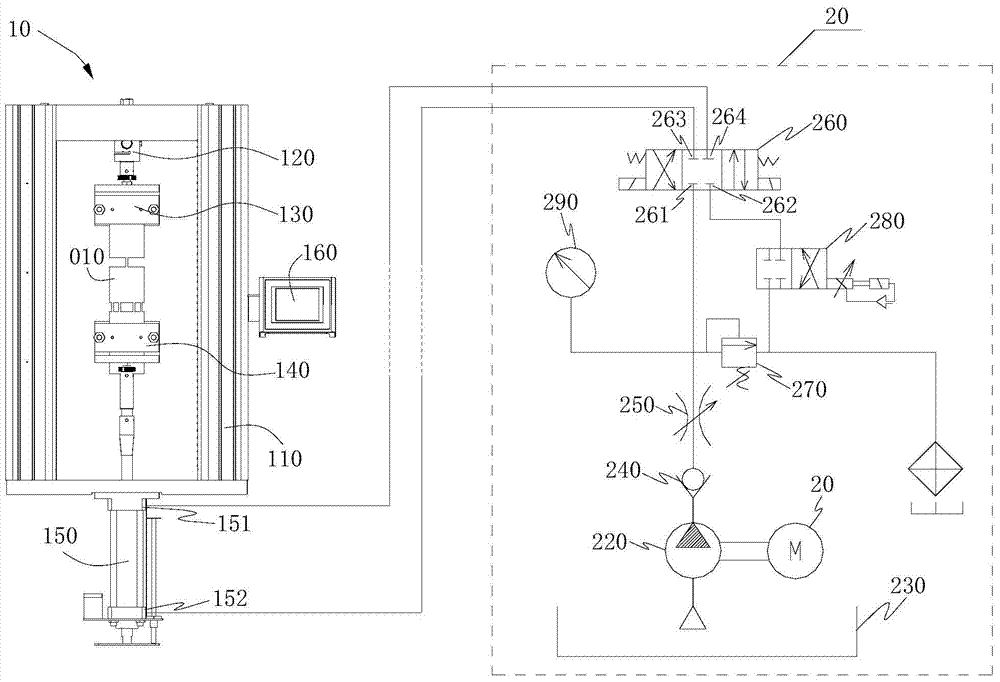

[0015] Such as figure 2 Shown, it is the oil pressure control system 20 of the present invention and figure 1 The connection diagram of the tape fatigue test apparatus 10 shown in .

[0016] The oil pressure control system 20 includes: a motor 210 , an oil pump 220 , an oil tank 230 , a check valve 240 , a throttle valve 250 , a three-position four-way solenoid valve 260 , a pressure regulating valve 270 and a servo flow valve 280 .

[0017] The motor 210 is drivingly connected with the oil pump 220 to drive the oil pump 220 to extract the hydraulic oil in the oil tank 230 . Specifically, the drive shaft of the motor 210 rotates at a preset speed, and drives the oil pump 220 to pump out the hydraulic oil in the oil tank 230 . The oil pump 220 communicates with the throttle valve 250 through the check valve 240 . In practical application, the oil pump 220 communicates with the check valve 240 via the oil delivery pipe, and the check valve 240 communicates with the throttle v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com