Hydroxyl activated carbon supported palladium catalyst and preparation method thereof

A technology of palladium catalyst and activated carbon, which is applied in the field of hydroxyl activated carbon-supported palladium catalyst and its preparation, can solve the problems of low selectivity and conversion rate of palladium carbon, easy deactivation of nickel-based catalyst, high cost, etc., and achieve enhanced force and good adhesion The effect of point position and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

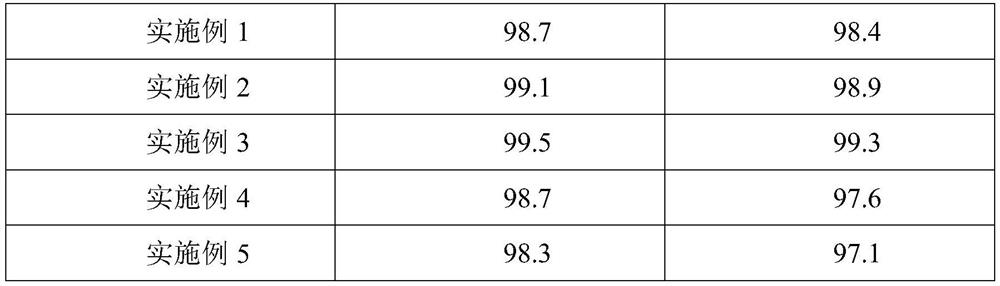

Embodiment 1

[0024] Embodiment 1, a kind of preparation method of hydroxyl activated carbon supported palladium catalyst, its steps are as follows:

[0025] Step 1, the preparation of sodium zincate modified activated carbon,

[0026] a) treating activated carbon, treating the activated carbon with nitric acid with a mass fraction of 5% at a temperature of 80° C. for 2 hours, and washing it into neutrality;

[0027] b) To prepare sodium zincate solution, mix 0.1g of sodium hydroxide per 100mL of deionized water for preparation, dissolve sodium hydroxide in the corresponding amount of deionized water, add excess zinc powder, and react at a temperature of 40°C 1h, and then filter to remove insolubles to obtain a clear filtrate;

[0028] c) The activated carbon obtained in the above a) and the sodium zincate solution obtained in the above b) are made into a slurry, stirred at 60° C. for 20 min, then filtered, repeated stirring and filtering 3 times, and finally washed with deionized water un...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of hydroxyl activated carbon supported palladium catalyst, its steps are as follows:

[0031] Step 1, the preparation of sodium zincate modified activated carbon,

[0032] a) treating activated carbon, treating the activated carbon with nitric acid with a mass fraction of 5% at a temperature of 80° C. for 2 hours, and washing it into neutrality;

[0033] b) To prepare sodium zincate solution, mix 0.2g of sodium hydroxide per 100mL of deionized water for preparation, dissolve sodium hydroxide in corresponding amount of deionized water, add excess zinc powder, and react at a temperature of 40°C 1h, and then filter to remove insolubles to obtain a clear filtrate;

[0034] c) The activated carbon obtained in the above a) and the sodium zincate solution obtained in the above b) are made into a slurry, stirred at 60° C. for 20 min, then filtered, repeated stirring and filtering 3 times, and finally washed with deionized water until ...

Embodiment 3

[0036] Embodiment 3, a kind of preparation method of hydroxyl activated carbon supported palladium catalyst, its steps are as follows:

[0037] Step 1, the preparation of sodium zincate modified activated carbon,

[0038] a) treating activated carbon, treating the activated carbon with nitric acid with a mass fraction of 5% at a temperature of 80° C. for 2 hours, and washing it into neutrality;

[0039] b) To prepare sodium zincate solution, mix 0.5g of sodium hydroxide per 100mL of deionized water for preparation, dissolve sodium hydroxide in the corresponding amount of deionized water, add excess zinc powder, and react at a temperature of 40°C 1h, and then filter to remove insolubles to obtain a clear filtrate;

[0040]c) The activated carbon obtained in the above a) and the sodium zincate solution obtained in the above b) are made into a slurry, stirred at 60° C. for 20 min, then filtered, repeated stirring and filtering 3 times, and finally washed with deionized water unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com