Double-roller type crushing sand making machine with adjustable tightness degree

一种制砂机、辊式的技术,应用在对辊式粉碎制砂机领域,能够解决辊筒磨损大、噪音大、耗能大等问题,达到可靠粉碎效果、好节能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

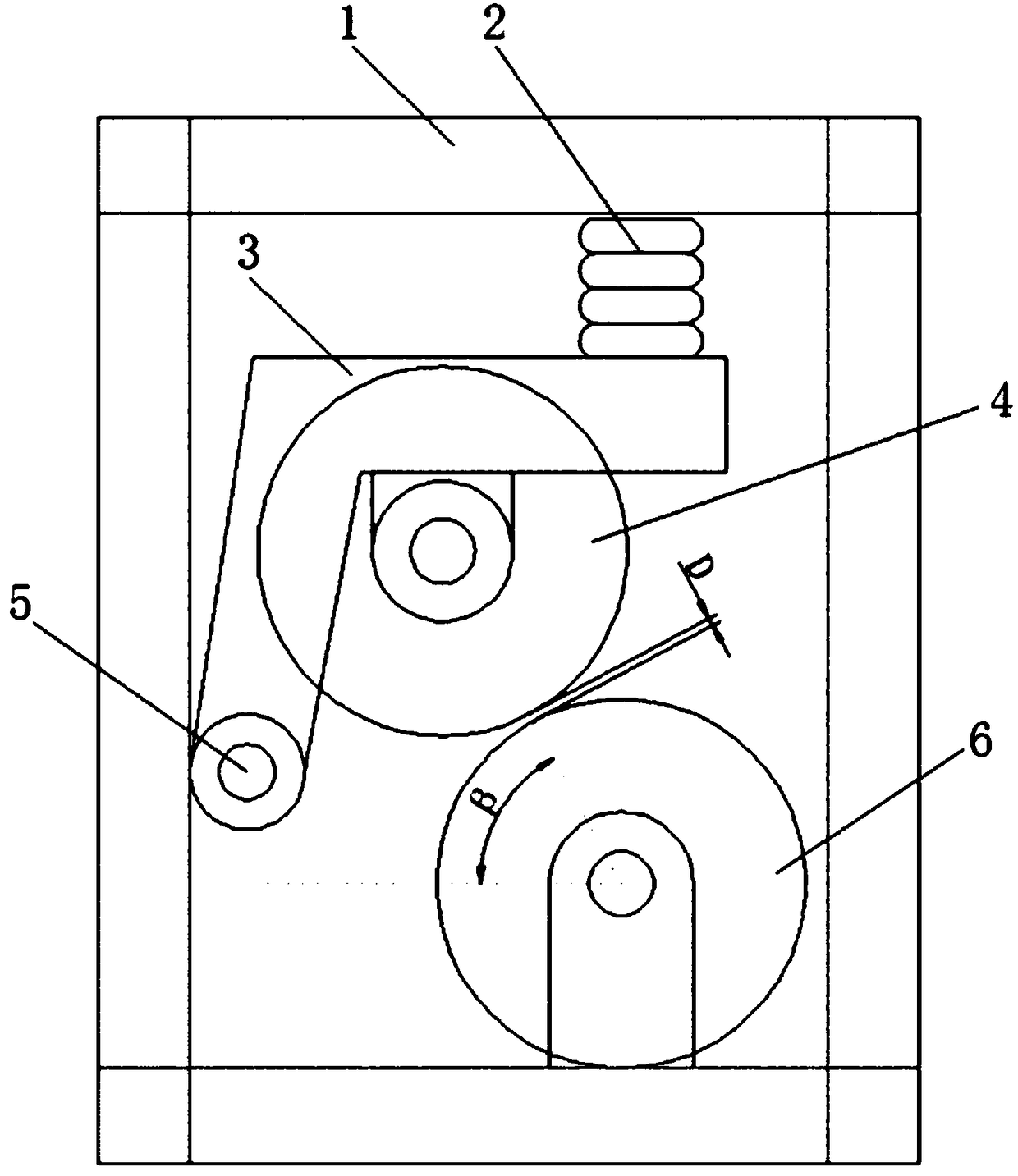

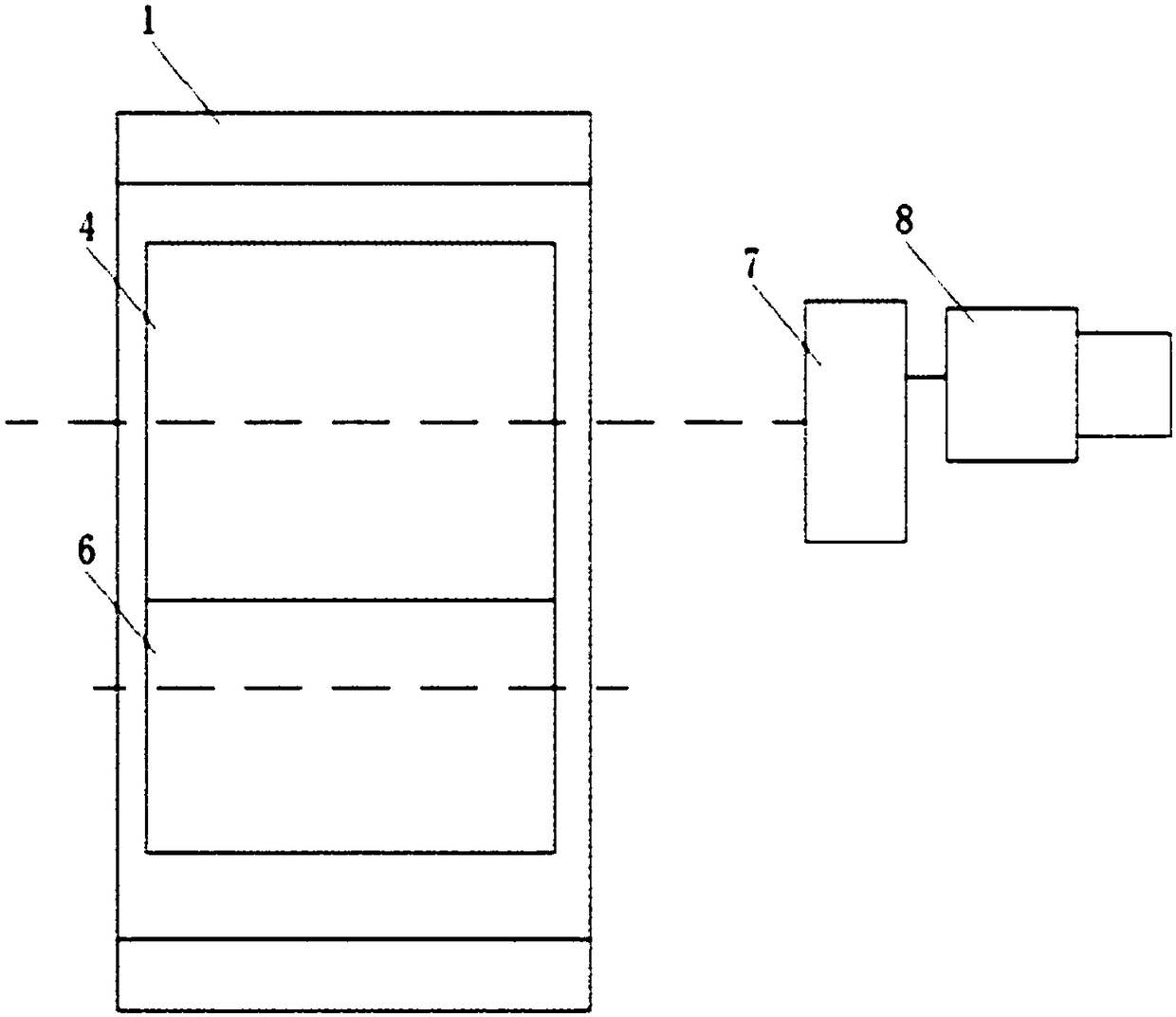

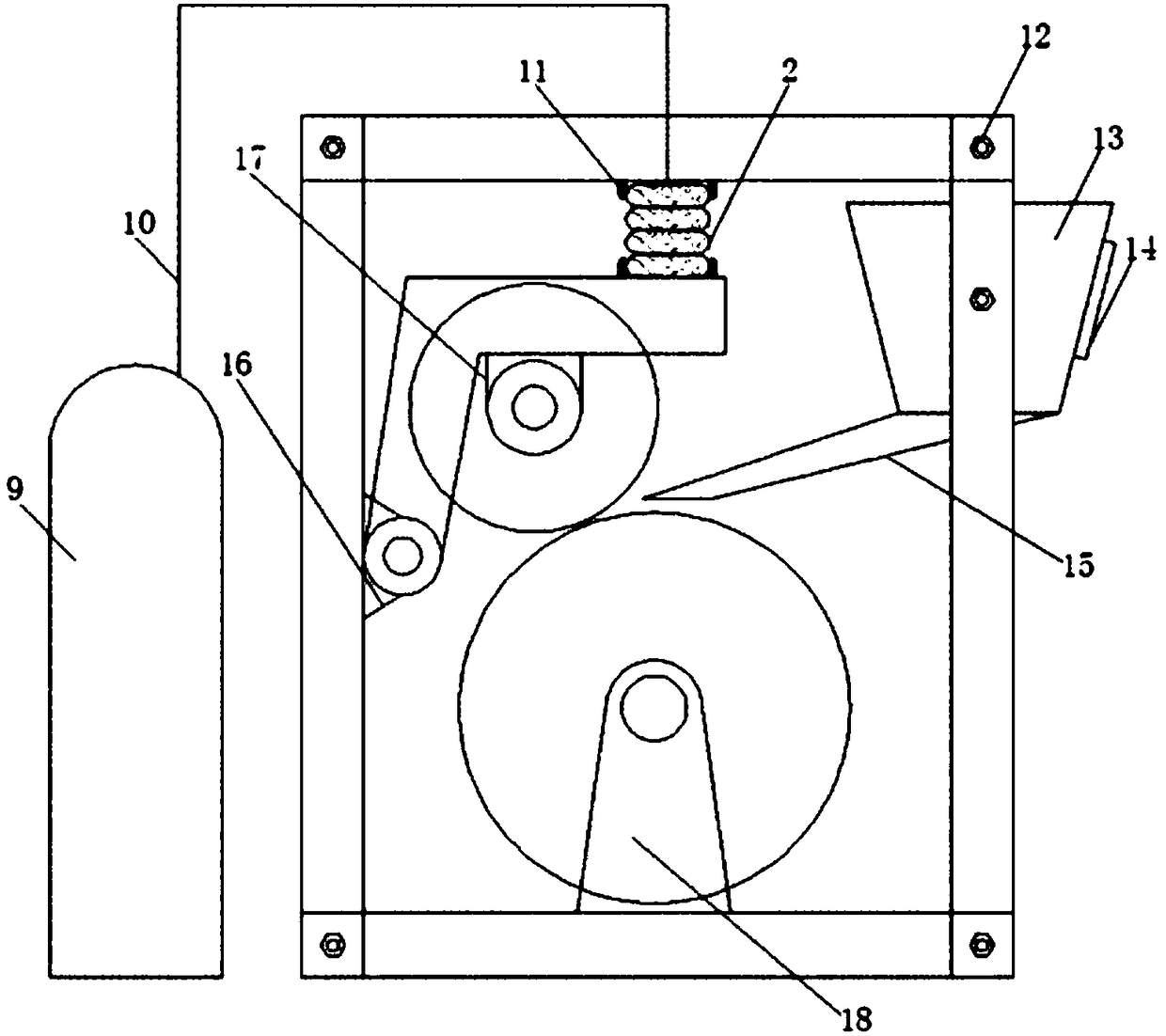

[0037] Such as Figure 1~5 As shown, it shows a specific embodiment of the present invention. As shown in the figure, a pair of roller crushing sand making machine of the present invention includes an active roller 4 and a passive roller 6; The axis is parallel; the center connecting line of the same section of the active roller and the passive roller has an angle β with the negative X axis of the section, and 75°<β<90°; the active roller and the passive roller The distance between the closest points on the circumferential surface of the same section of the roller is D, and 0≤D≤3mm;

[0038] As shown in the figure, the two ends of the active roller 4 and the passive roller 6 are coaxially arranged with end shafts, and the two ends of the passive roller are rotatably installed on the frame 1; the end shafts of the active roller on both sides of the active roller Rotatingly mounted on the rotary arm 3; the rotary arm is rotatably mounted on the bearing of the rotary bearing seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com