Automatic collecting device for bearing sleeve

A technology for automatic collection and bearing sleeves, applied in metal processing and other directions, can solve the problems of inability to realize automatic and rapid collection of bearing sleeves, slow sorting speed, and high labor costs, and achieve the effects of saving labor and material resources, accurate rotation angle, and simple transmission structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

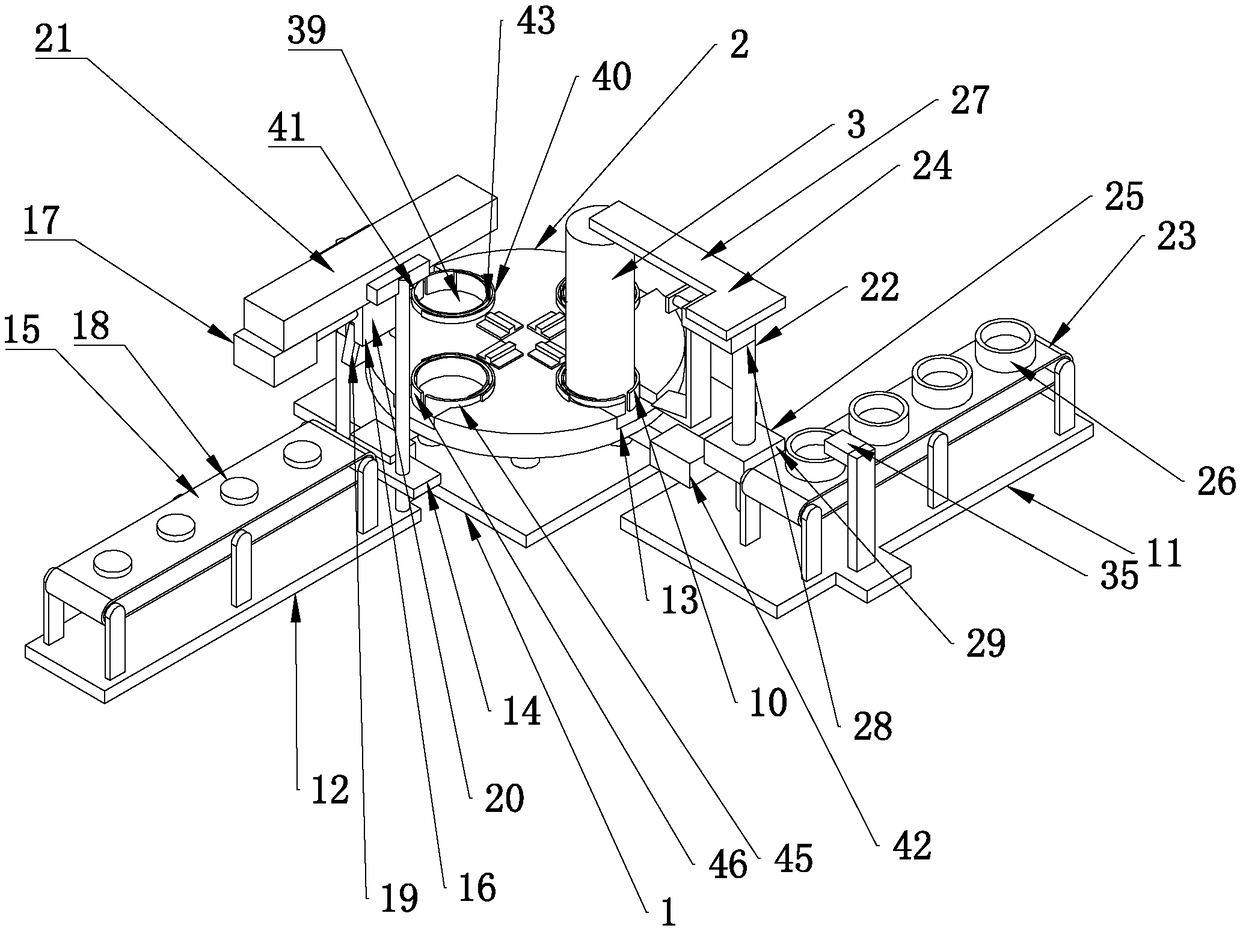

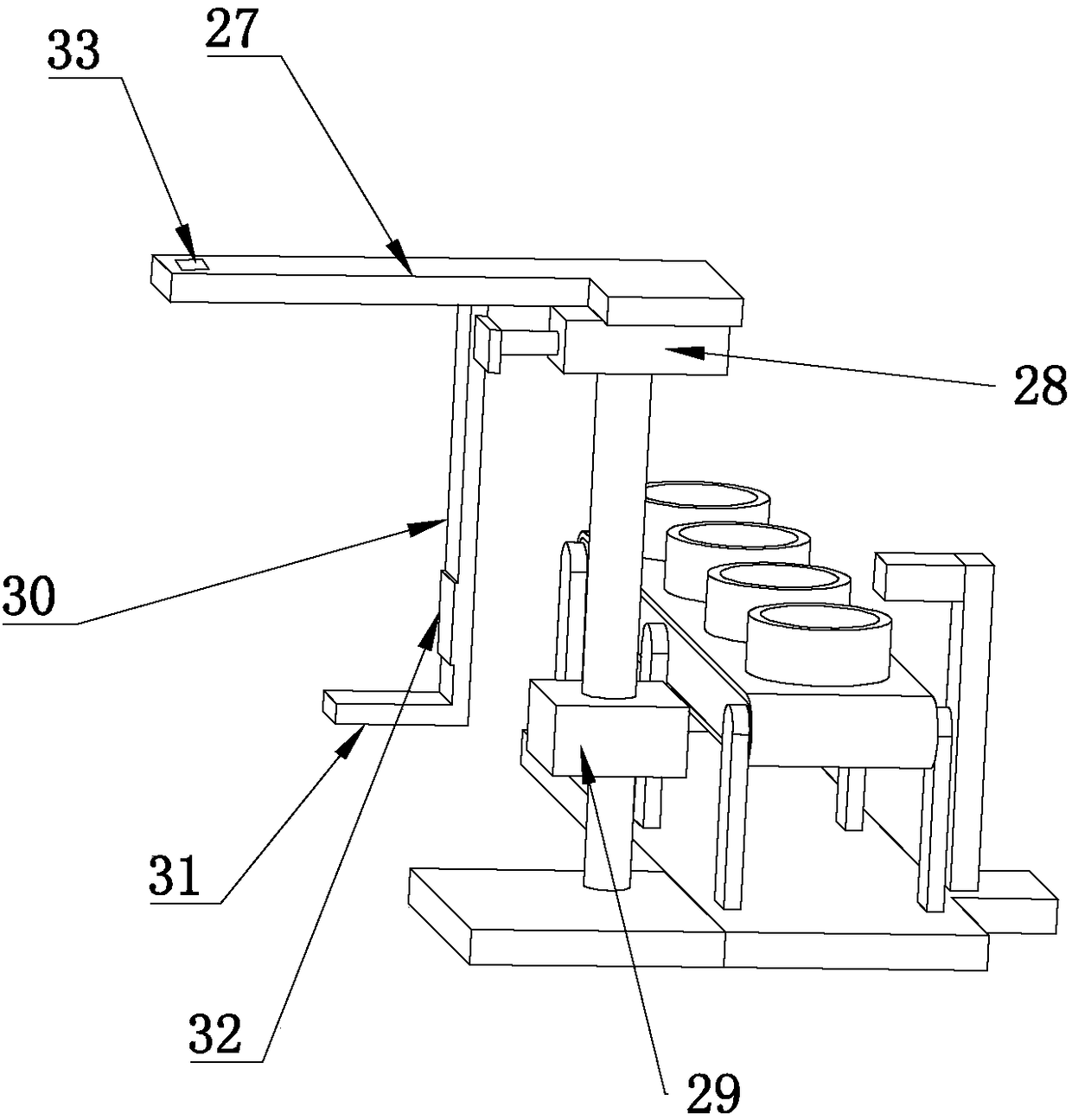

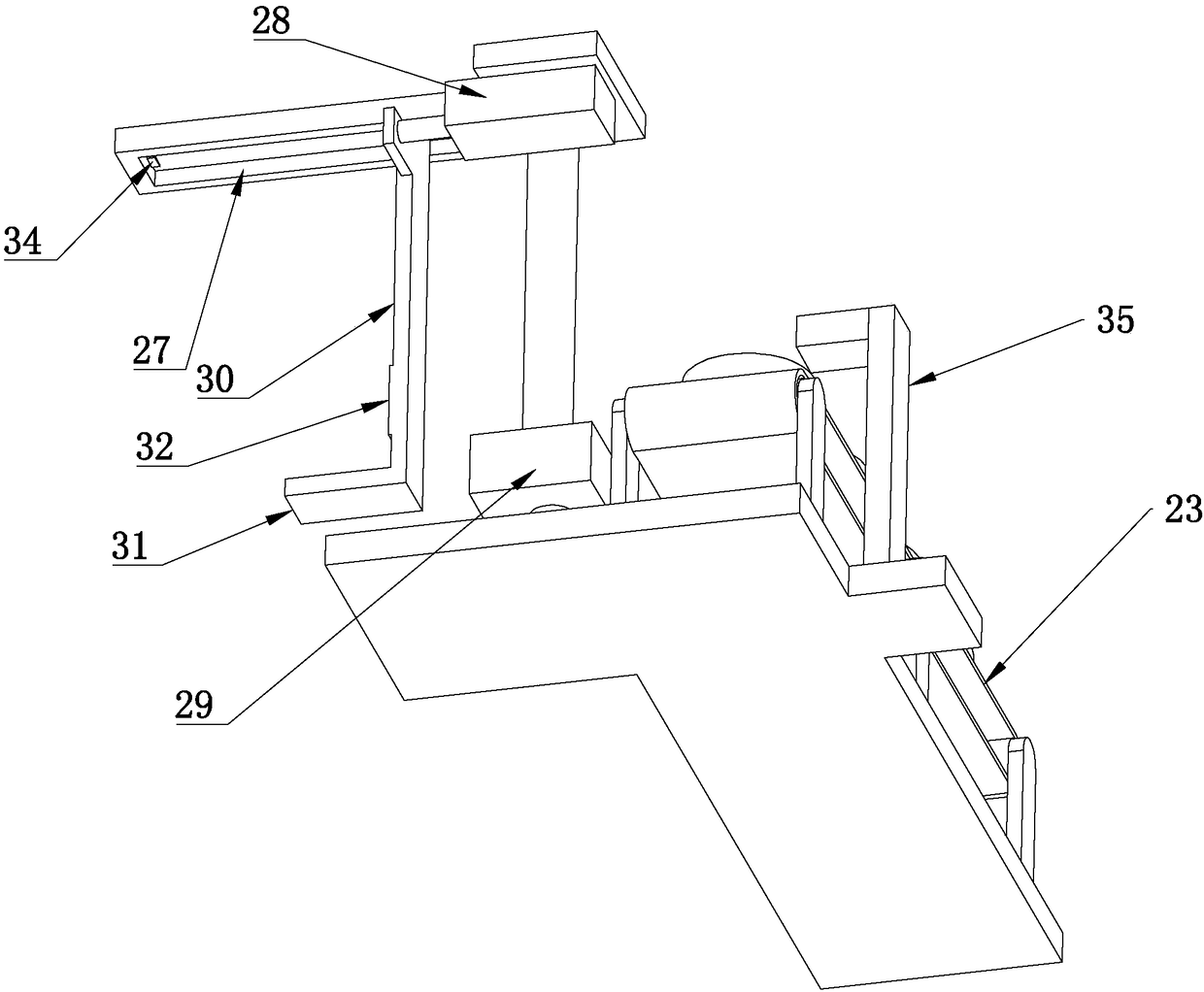

[0037] As an improved specific embodiment, the unloading device 11 includes a second installation frame 22, a second conveyor belt 23, a transfer frame 24, and a driving assembly 25 that drives the transfer frame 24 to move between the mounting base 10 and the second conveyor belt 23 , the second conveyor belt 23 is provided with several second receiving seats 26 arranged at equal intervals, and the second conveyor belt 23 is used to transfer the fully loaded collection cylinder 3 to the next station,

[0038] The second installation frame 22 is provided with a sliding seat 27, the transfer frame 24 is slidably connected with the sliding seat 27, the sliding seat 27 is arranged in parallel with the pushing groove 13, and the sliding seat 27 is connected with the second The mounting frame 22 is rotationally connected, and the driving assembly 25 includes a second driving device 28 and a third driving device 29, the second driving device 28 drives the transfer frame 24 to slide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com