Special system and method for automatically breaking soft film without damage for isostatic-pressing forming products

An isostatic forming and non-damaging technology, which is applied in the field of soft film automatic demolition systems, can solve the problems of easily damaged products, time-consuming, and labor-consuming problems, and achieve the effects of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0027] After isostatic pressing, due to the effect of internal vacuum, the soft film is in a state of close contact with the product, and the soft film must be destructively removed when the product is taken out. Since the soft film is made of rubber material and has good elasticity, cutting the soft rubber film with a high-speed rotating blade can effectively solve the problem of difficult cutting due to elastic deformation of the rubber. The sawtooth blade is suitable for the rotating blade. Moreover, the soft film is closely attached to the product, and direct cutting is easy to damage the product. Therefore, it is necessary to separate the soft film from the product before cutting. The specific plan is as follows:

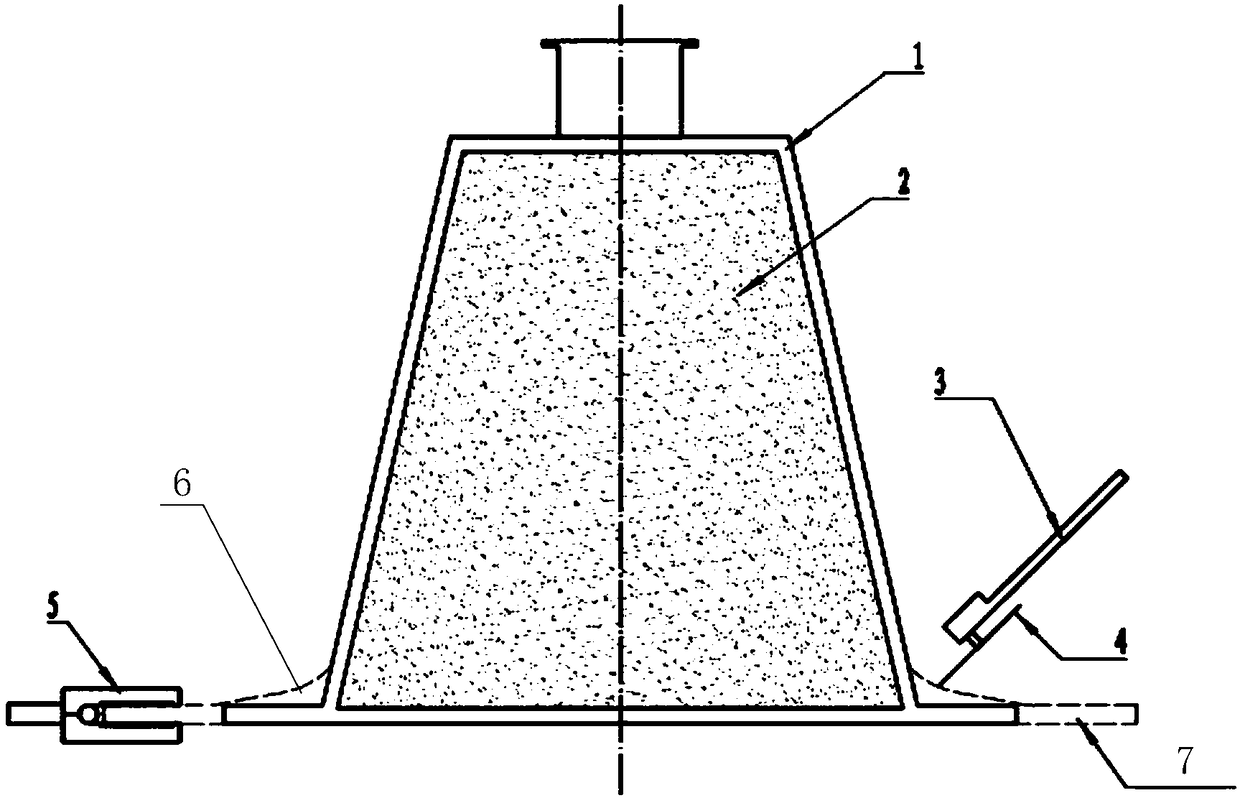

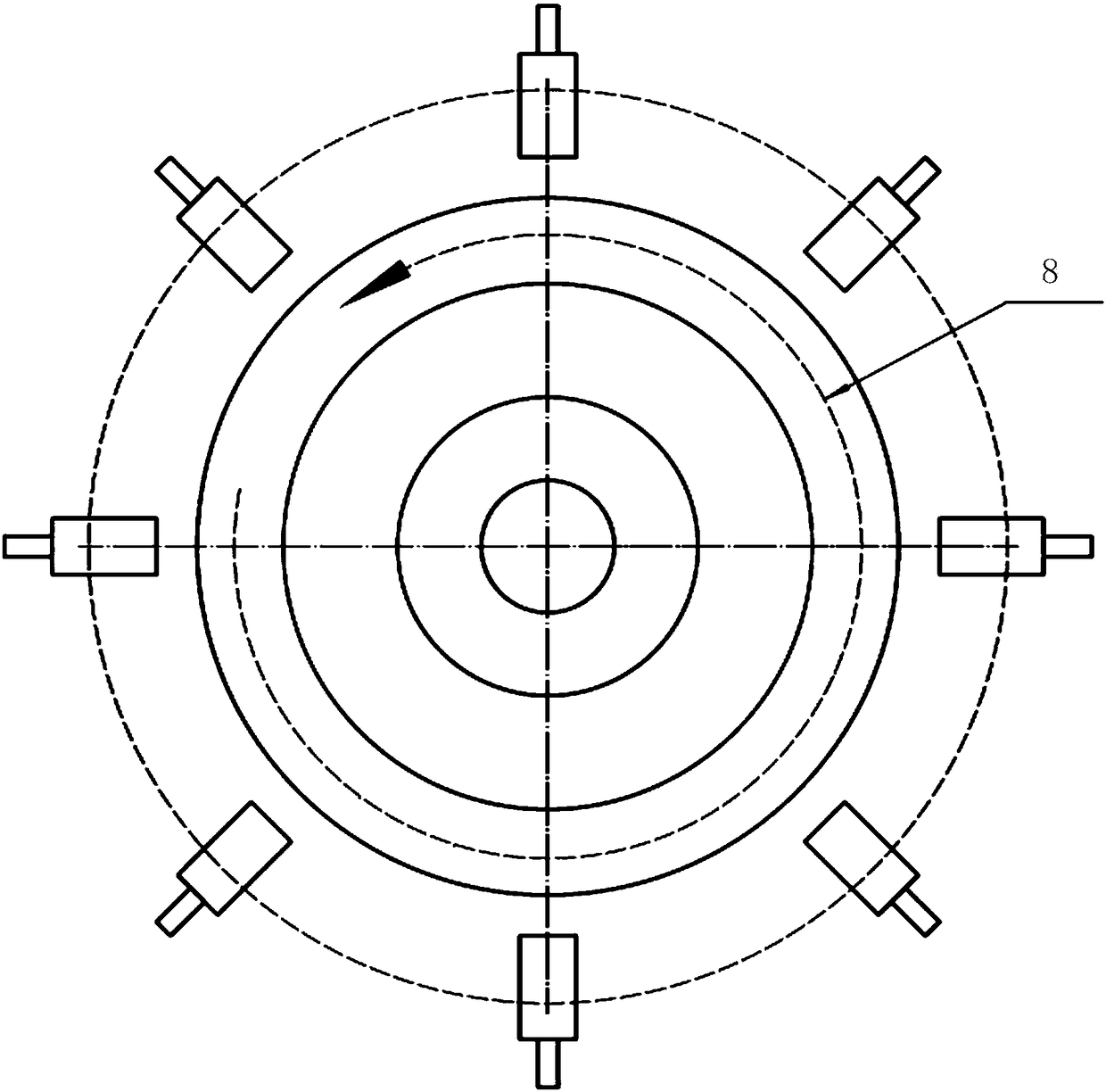

[0028] like figure 1 and figure 2 as shown, figure 1 It shows the front structure de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com