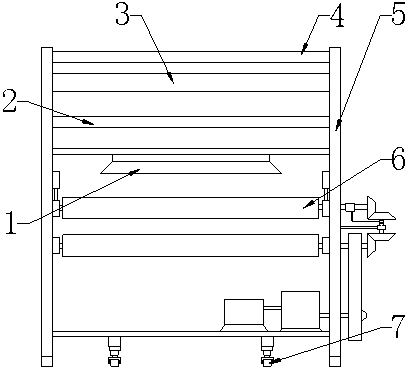

Color printing packaging coated film device

A technology of laminating device and color printing, applied in printing, printing machine, general parts of printing machinery, etc., can solve the problems of increasing labor cost, increasing transportation cost, narrow application range, etc., so as to speed up cleaning and reduce labor costs. Cleaning costs, the effect of improving printing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

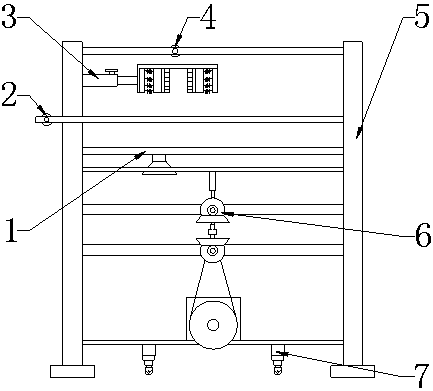

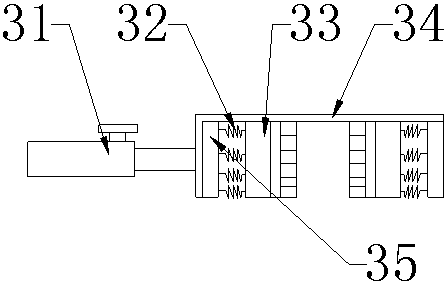

[0029] The specific embodiment: when in use, the staff pulls the packaging film down from the film release roller 4, and passes through the inner ends of the two cleaning brushes 33, then bypasses the electrostatic tension roller 2, and is arranged on the upper pressure roller 61 and The cleaning brush 33 between the lower pressure rollers is lowered by the elastic force of the spring 32 and the packaging film is pressed tightly. When the packaging film moves, the cleaning brush 33 and the packaging film will move relative to each other, and the cleaning brush 33 will clean the packaging film. The design improves the cleaning work efficiency.

[0030] When the staff needs to adjust the distance between the upper pressing roller 61 and the lower pressing roller, the staff turns on the electric cylinder, and the electric cylinder works to drive the bearing ring 2 and the upper pressing roller 61 to move upwards, and the upper pressing roller 61 moves upwards to drive the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com