Conveyor

A transmission device and transmission device technology, applied in the direction of conveyors, transportation and packaging, drying solid materials, etc., can solve the problems of limited punching process, poor softness of metal mesh, and difficult maintenance, etc., to reduce labor costs, Effect of increased performance and energy efficiency, good mechanical properties and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

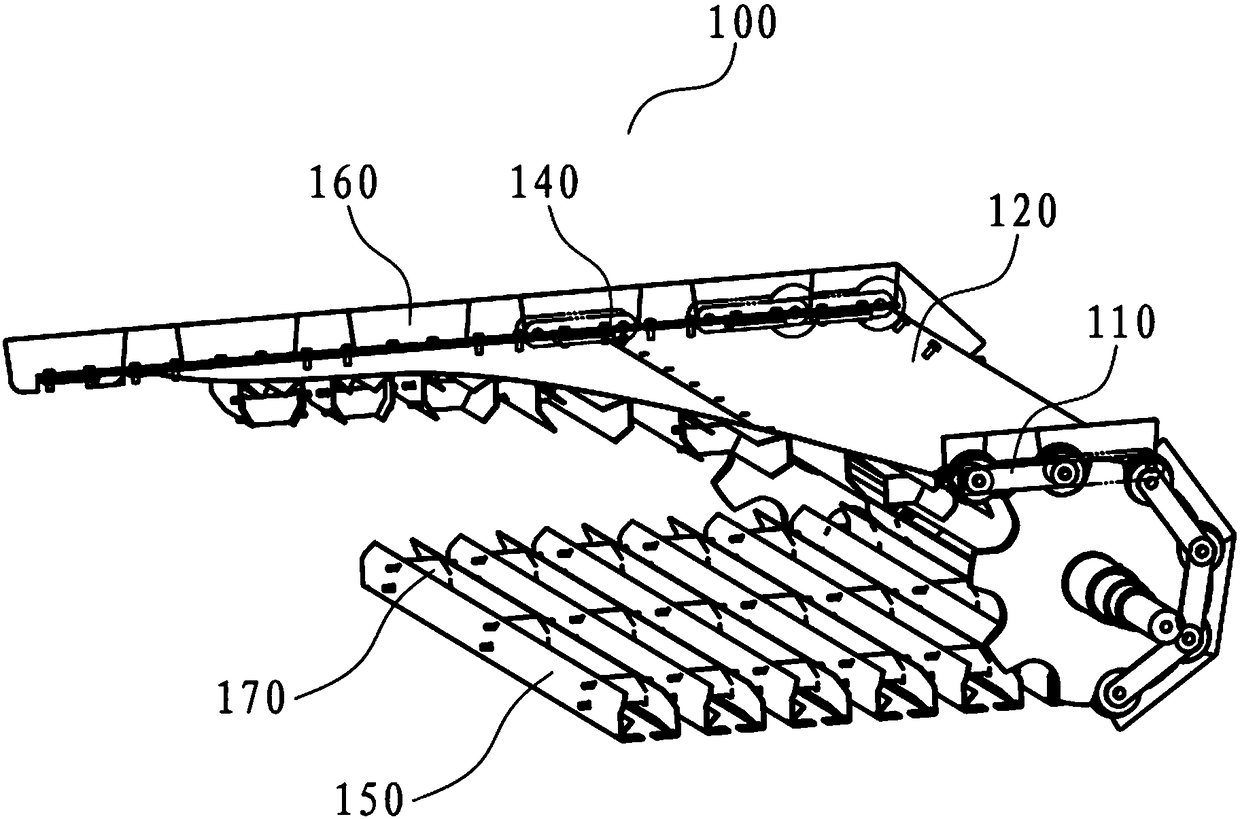

[0020] The conveying device 100 for the feed dryer of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the accompanying drawings are only for illustration and should not be construed as limiting the present invention.

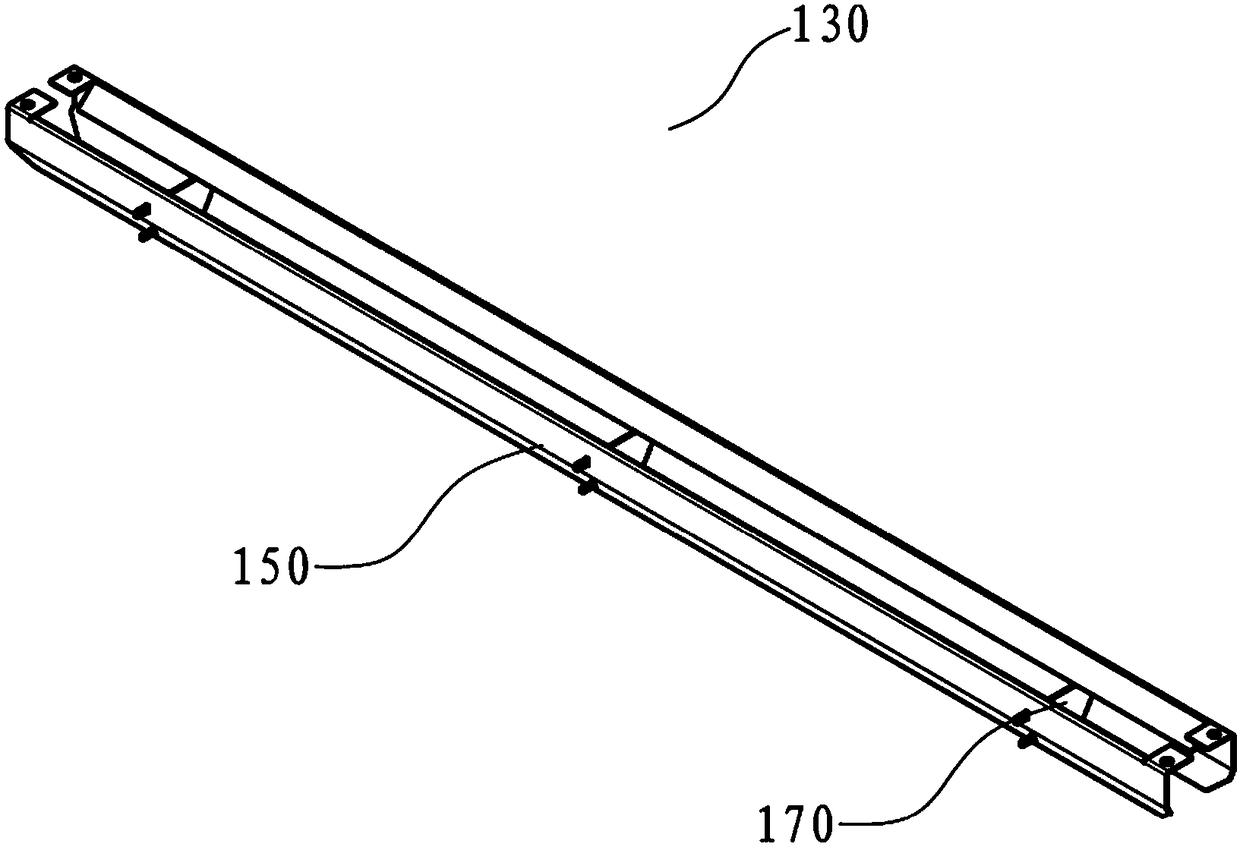

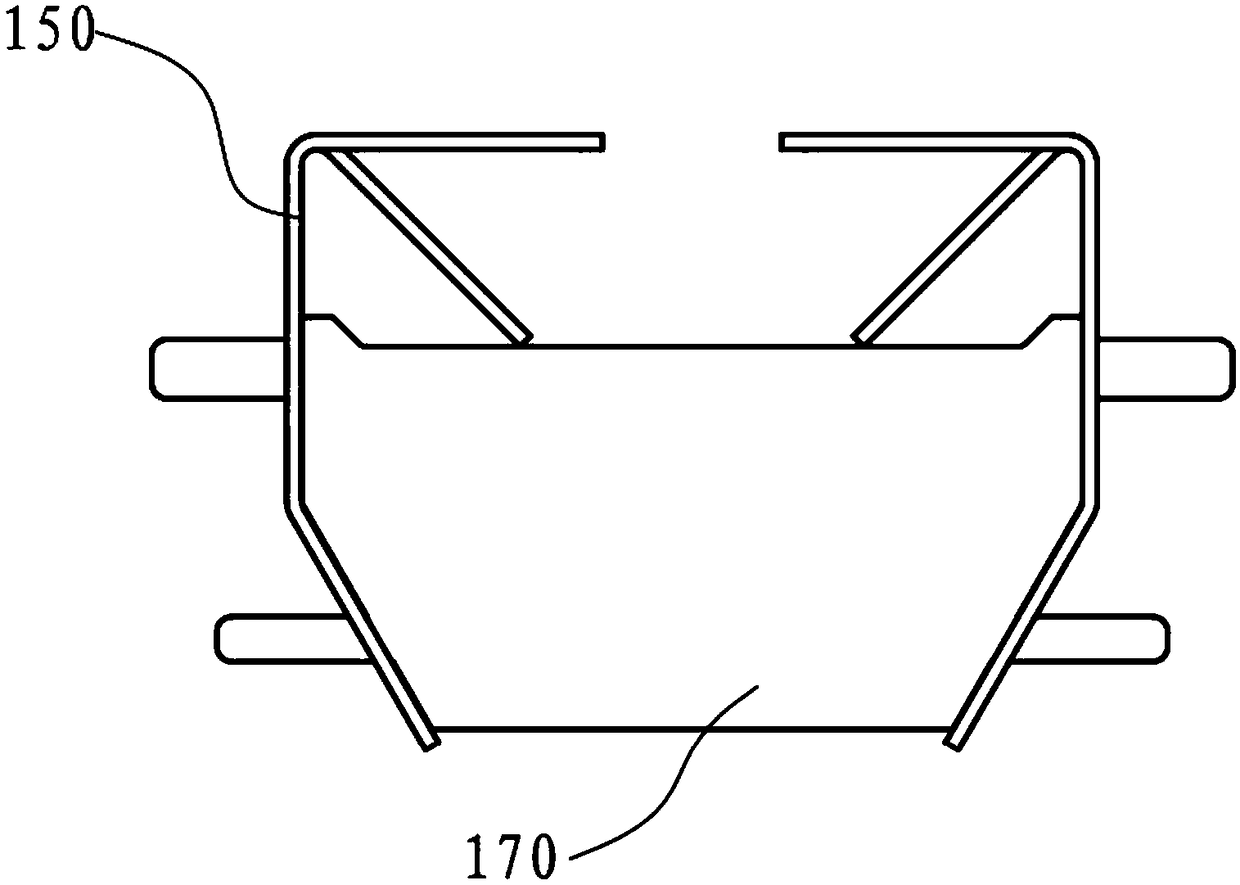

[0021] figure 1 Schematically shows the three-dimensional structural view of the support member 130 of the conveying device 100 for the feed dryer of the present invention, as figure 1 As shown, each supporting member 130 is composed of a pair of inverted V-shaped bent plates 150 and reinforcing ribs 170 . The length of the inverted V-shaped bent plate 150 used in actual production is equivalent to the width of the conveyor belt 120, so it has a relatively long length, and the reinforcing rib 170 here plays a role in fixing and preventing the reversed V-shaped bent plate 150 from twisting .

[0022] The two inverted V-shaped bent plates 150 of each support member 130 can have variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com