Carpet cutting device

A cutting device and carpet technology, which is applied in textiles, papermaking, and textile material cutting, can solve the problems of prolonging the carpet processing cycle and not being able to cut carpets, and achieve the effect of shortening the processing cycle and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

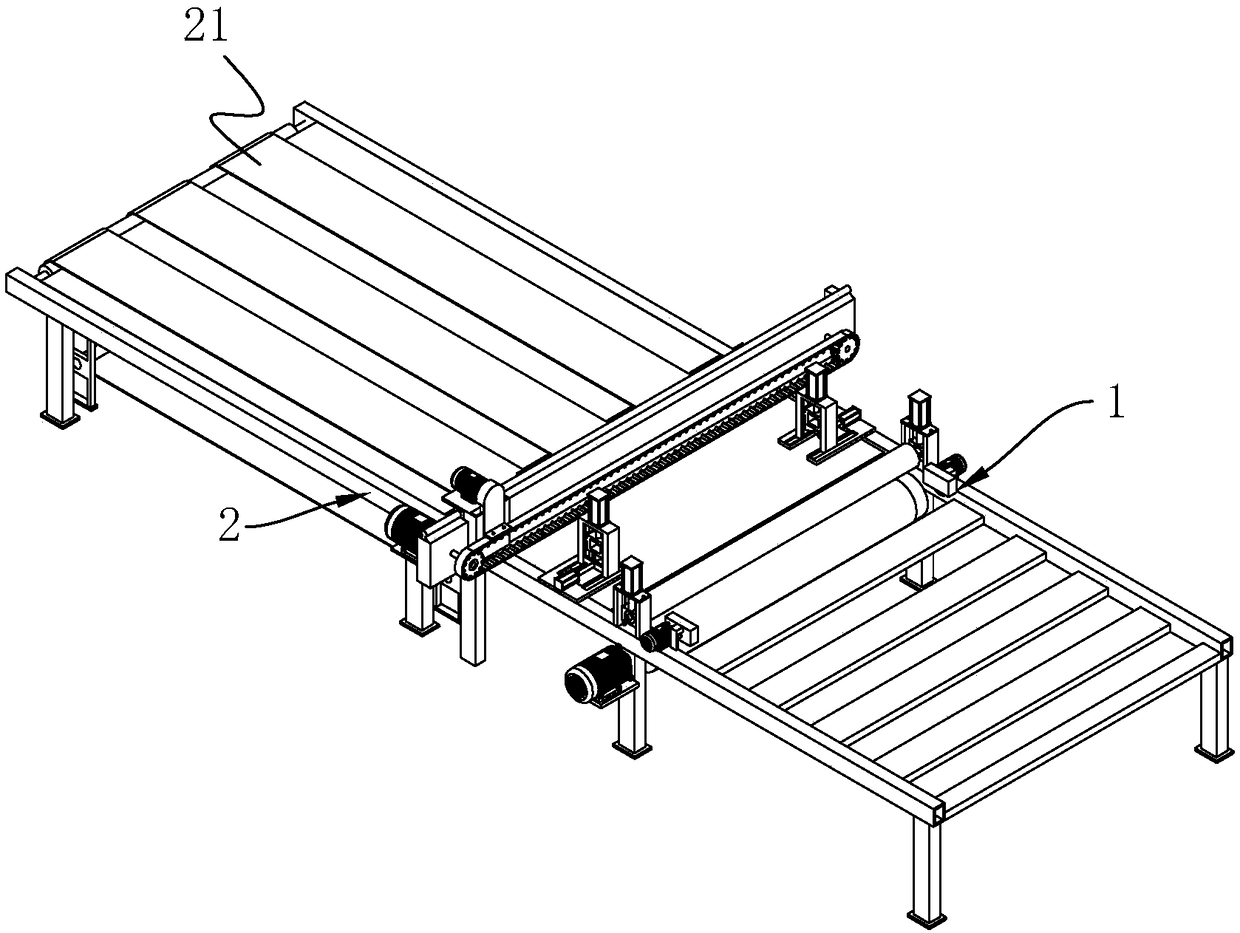

[0045] A kind of carpet cutting device, seefigure 1 , including a support 1 and a transfer frame 2 arranged on one side of the support 1 .

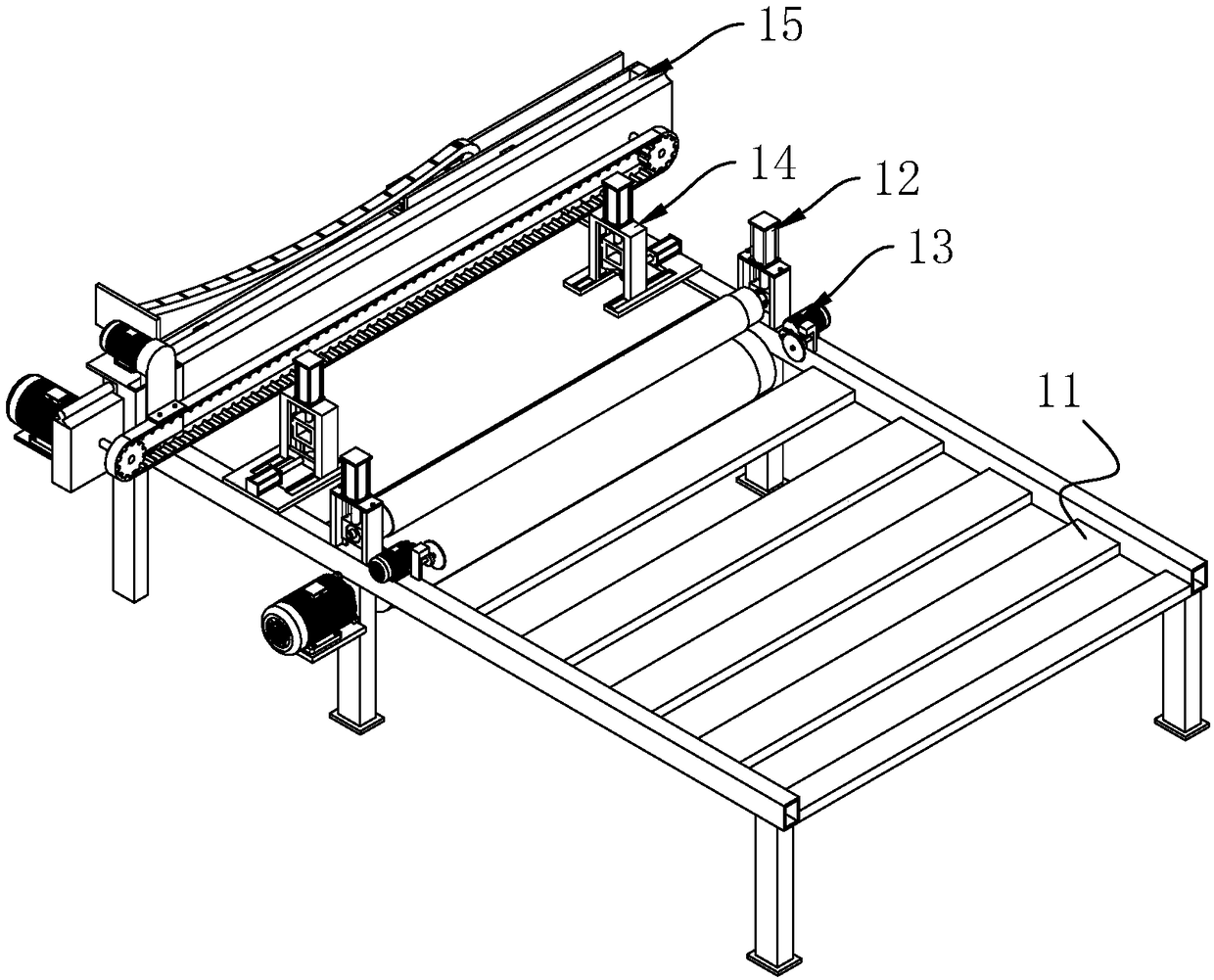

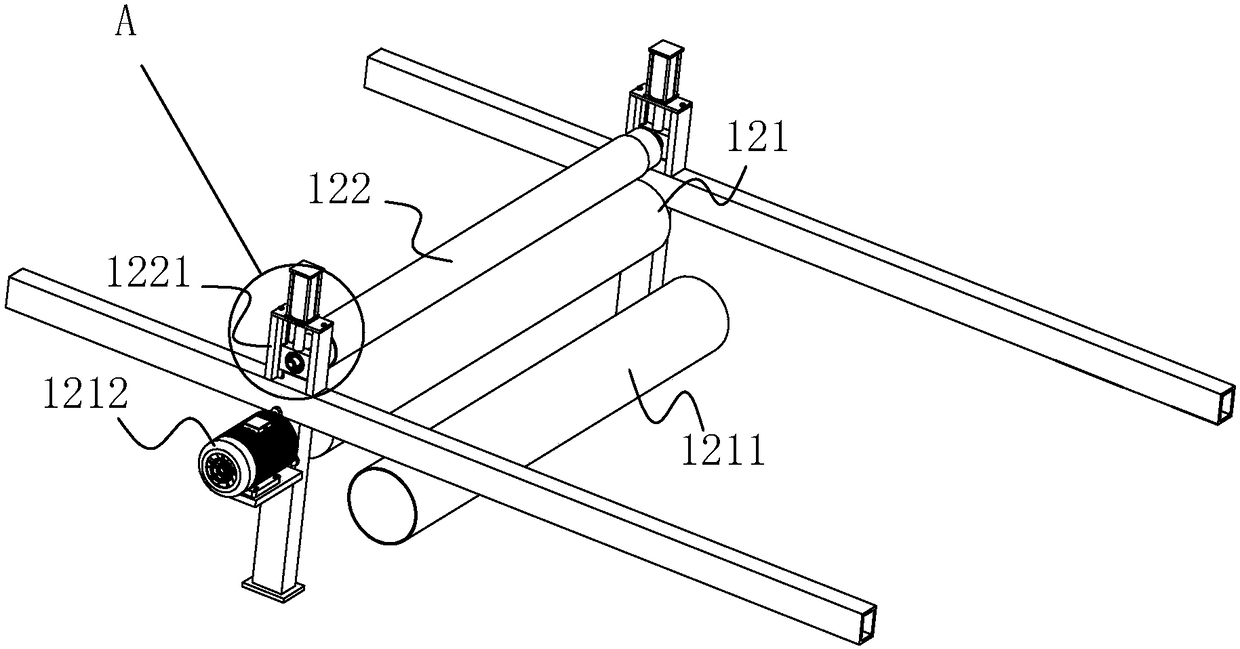

[0046] see figure 2 The end of the bracket 1 away from the transmission frame 2 is fixed with a plurality of bearing plates 11, and the two sides of the bracket 1 between the load plate 11 and the transmission frame 2 are sequentially provided with an edge trimming mechanism 13, a transmission mechanism 12, and a corner cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com