Post-trigger type door leaf linkage structure

A post-trigger and door leaf technology, which is applied in building locks, building structures, building fastening devices, etc., can solve the problems of high transmission pressure of the main lock body, high production cost of the main lock body, and easy wear and tear of the main lock body. Achieve the effects of improving anti-theft performance, increasing service life and reducing transmission pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

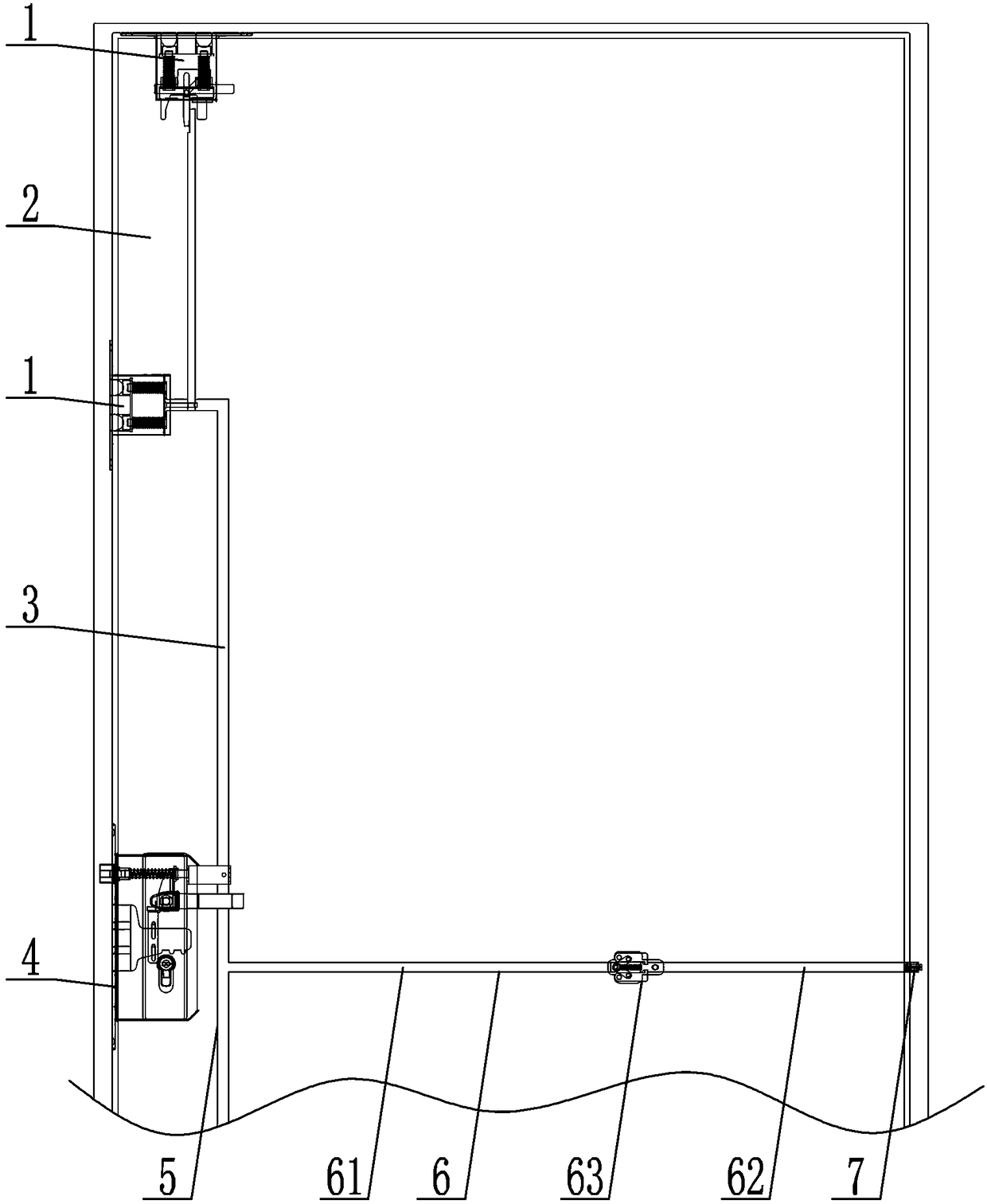

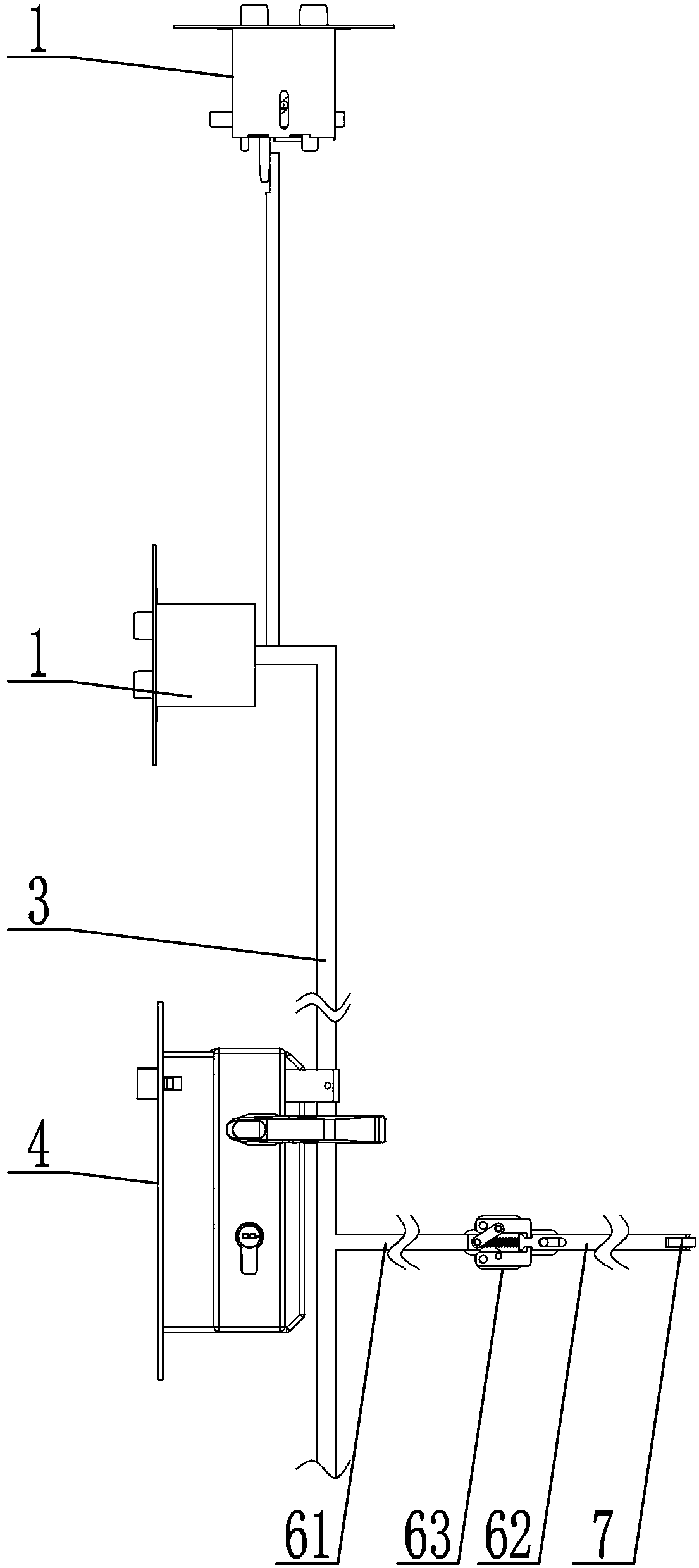

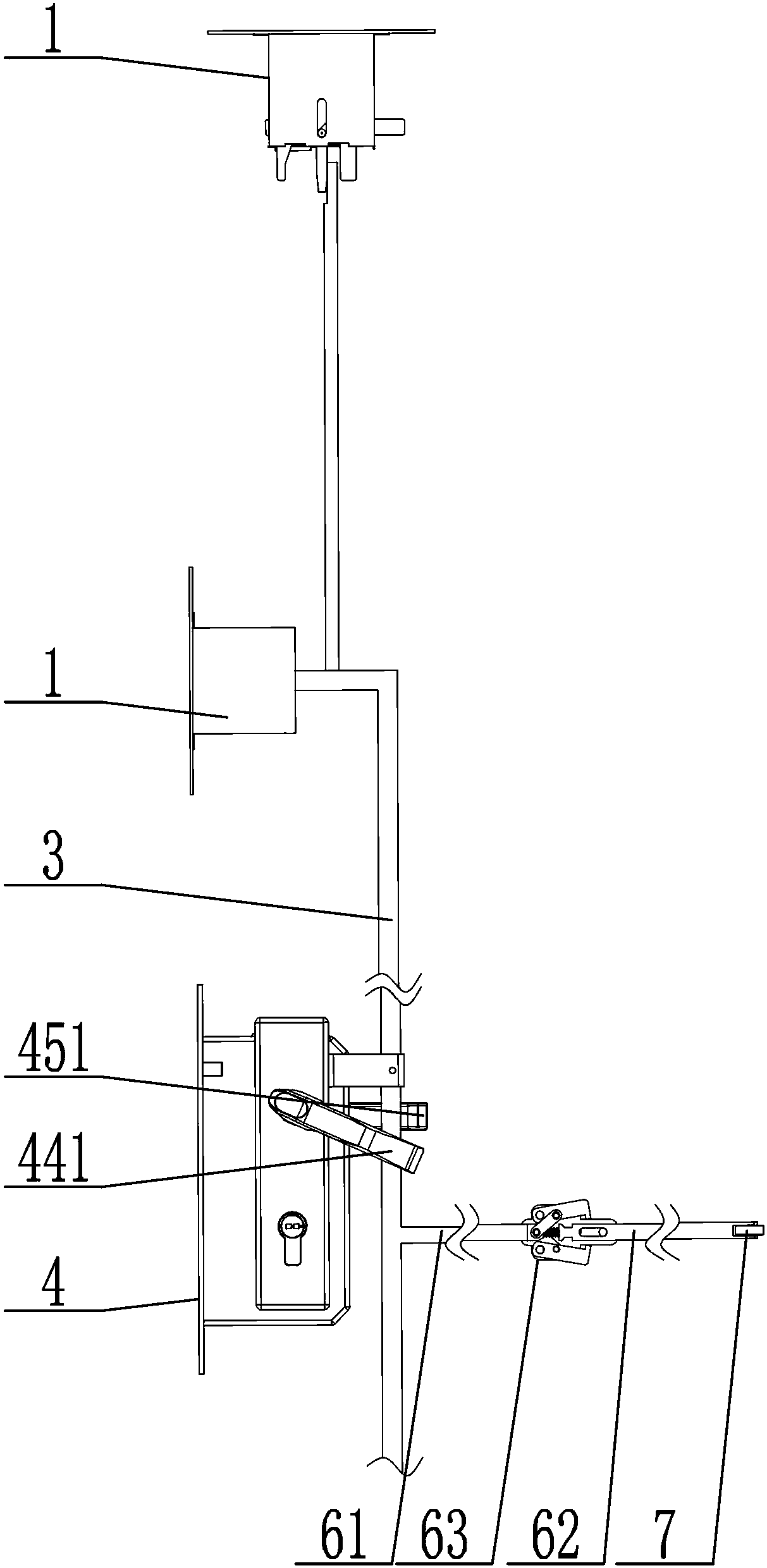

[0045] Such as Figure 1 to Figure 14 As shown, a rear-triggered door leaf interlocking structure includes a door leaf 2, a main lock body 4, a connecting rod assembly 5, and an anti-theft lock point assembly 1. The main lock body 4 is arranged on the outside of the door leaf 2 and connected to the connecting rod The anti-theft lock point assembly 1 is arranged on the frame of the door leaf 2 and connected with the connecting rod assembly 5, and also includes a contact point 7, and the connecting rod assembly 5 includes interconnected transverse connecting rod assemblies 6 . The longitudinal link assembly 3, the contact point 7 is arranged at the rear end of the transverse link assembly 6 and inside the door leaf 2, the anti-theft lock point assembly 1 is arranged on the longitudinal link assembly 3, The contact 7 drives the longitudinal link assembly 3 to move outward through the transverse link assembly 6 and drives the anti-theft lock point assembly 1 to lock to form a lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com