Rapid cleaning equipment for textiles

A technology for cleaning equipment and textiles, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing. It can solve problems such as poor cleaning efficiency, improve efficiency, prevent environmental pollution, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

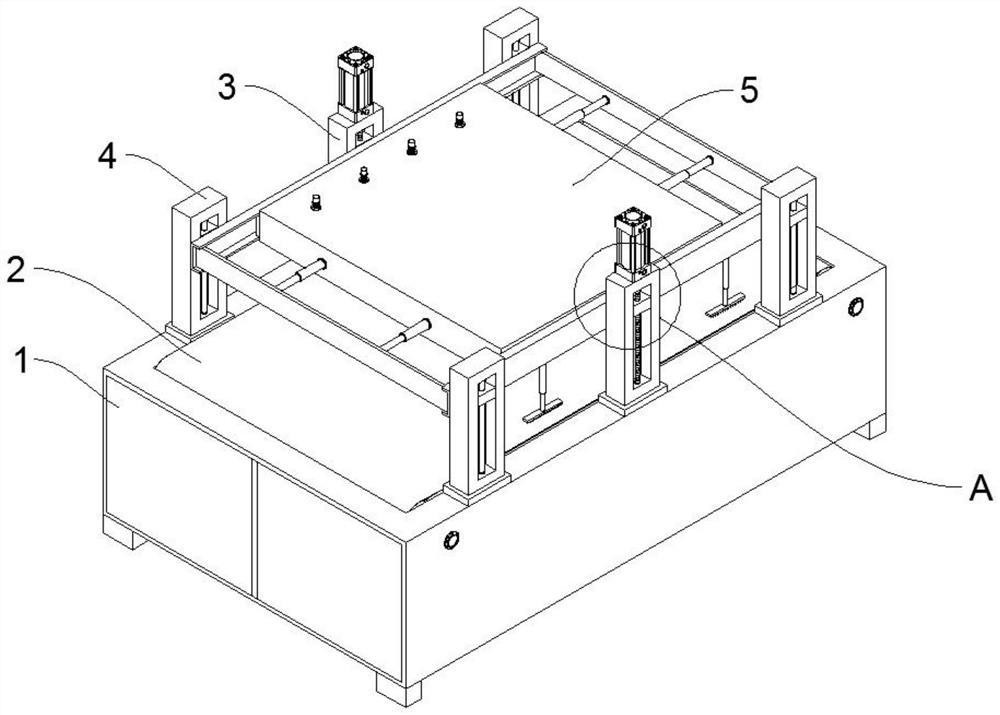

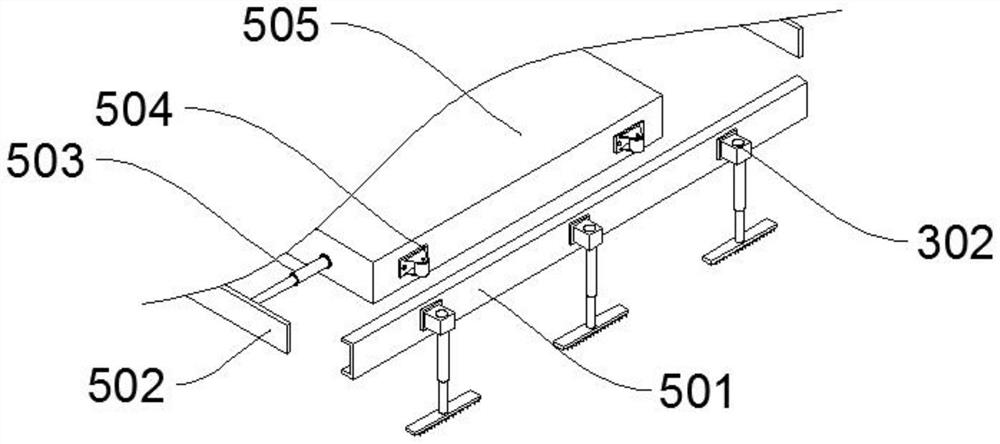

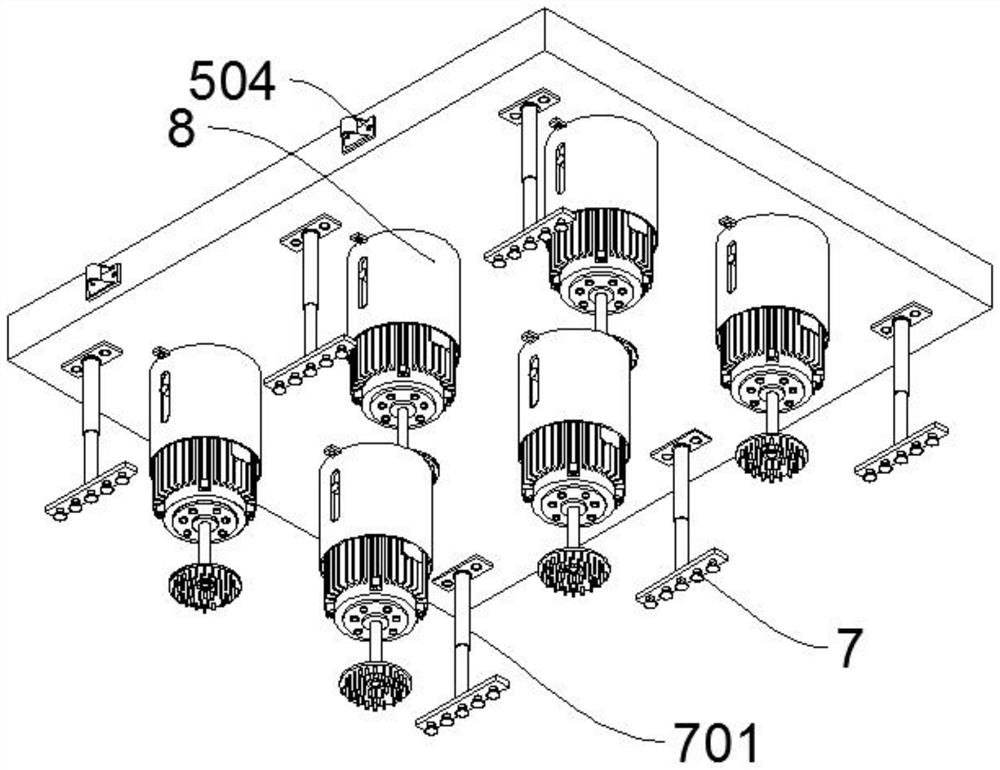

[0039] Append figure 1 Attachment Figure 7 Looking:

[0040] The present invention provides a textile rapid cleaning apparatus including an operating table 1, a lifting mechanism 3, a sliding mechanism 5, a compression telescoping mechanism 6, a cleaning mechanism 8, and a filter mechanism 11, and the top mounting lifting mechanism 3 of the operating table 1. One side of the lift mechanism 3 is provided with a compression telescoping mechanism 6, and a sliding mechanism 5 is mounted between the lifting mechanism 3, and a cleaning mechanism 8 is mounted on both sides of the bottom end of the sliding mechanism 5, the cleaning mechanism 8. A transport mechanism 2 is provided below, and a filtering mechanism 11 is provided below the transfer mechanism 2.

[0041] Among them, the lifting mechanism 3 includes a main rising stage 304 and a sub-rising step 4, and a groove is provided on the surface of the main rising step 304, and the recess is vertically mounted with a threaded rod 303, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com