warm edge spacer

A spacer, warm edge technology, applied in construction, building components, coatings, etc., can solve problems such as failure to achieve success, limited improvement in thermal resistance, and large volume of thermal conductive tape, achieving good processability and small deformation. , the effect of large thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

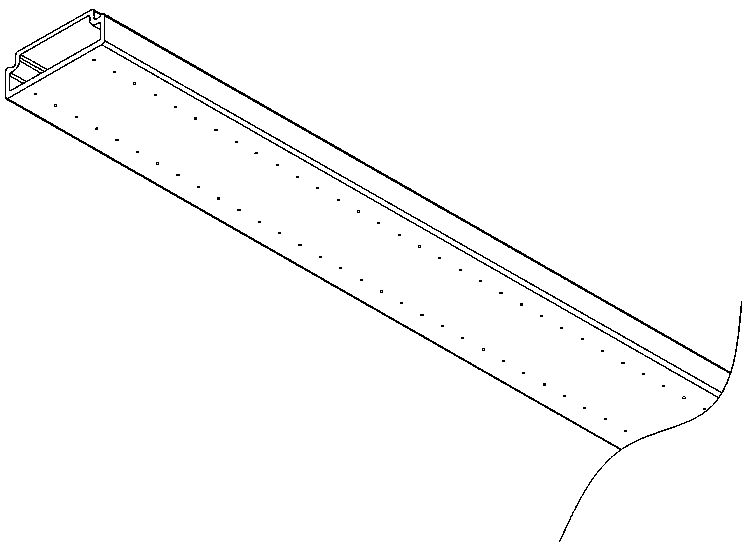

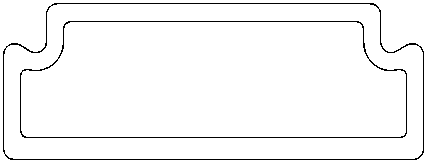

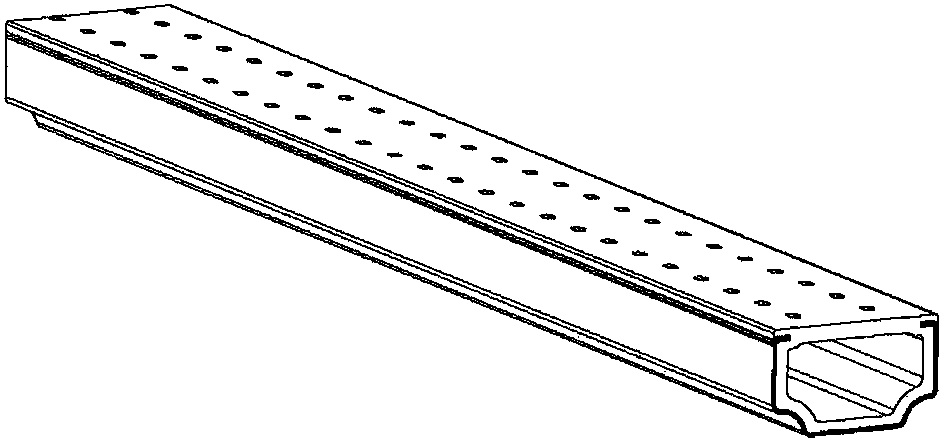

[0036] The warm edge spacer of this embodiment is a spacer profile applied in the edge area and / or edge of the insulating glass to form and maintain the space in the insulating glass.

[0037] Such as Figure 5 and Figure 6 As shown, the profile body includes a flat plastic strip 2 and a U-shaped metal strip 1. The top of the U-shaped metal strip has a pair of inwardly bent edges, and there is an occlusal structure on the edge. The flat plastic strip 2 is compounded with the occlusal structure. inner wall. The spacer profile extends in the longitudinal direction Z, has a width perpendicular to the longitudinal direction X in the transverse direction X, and has a height perpendicular to the longitudinal direction Z and the transverse direction X in the height direction Y. When the spacer profile is framed in the insulating glass, its inner wall faces the space in the insulating glass in the height direction, and the composite layer of the inner wall has a puncture hole. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com