Air valve correct time-lift adjusting mechanism

A technology of adjusting mechanism and valve timing, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of inability to adjust the valve timing and lift of the engine, and achieve the effect of easy promotion, convenient manufacture and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

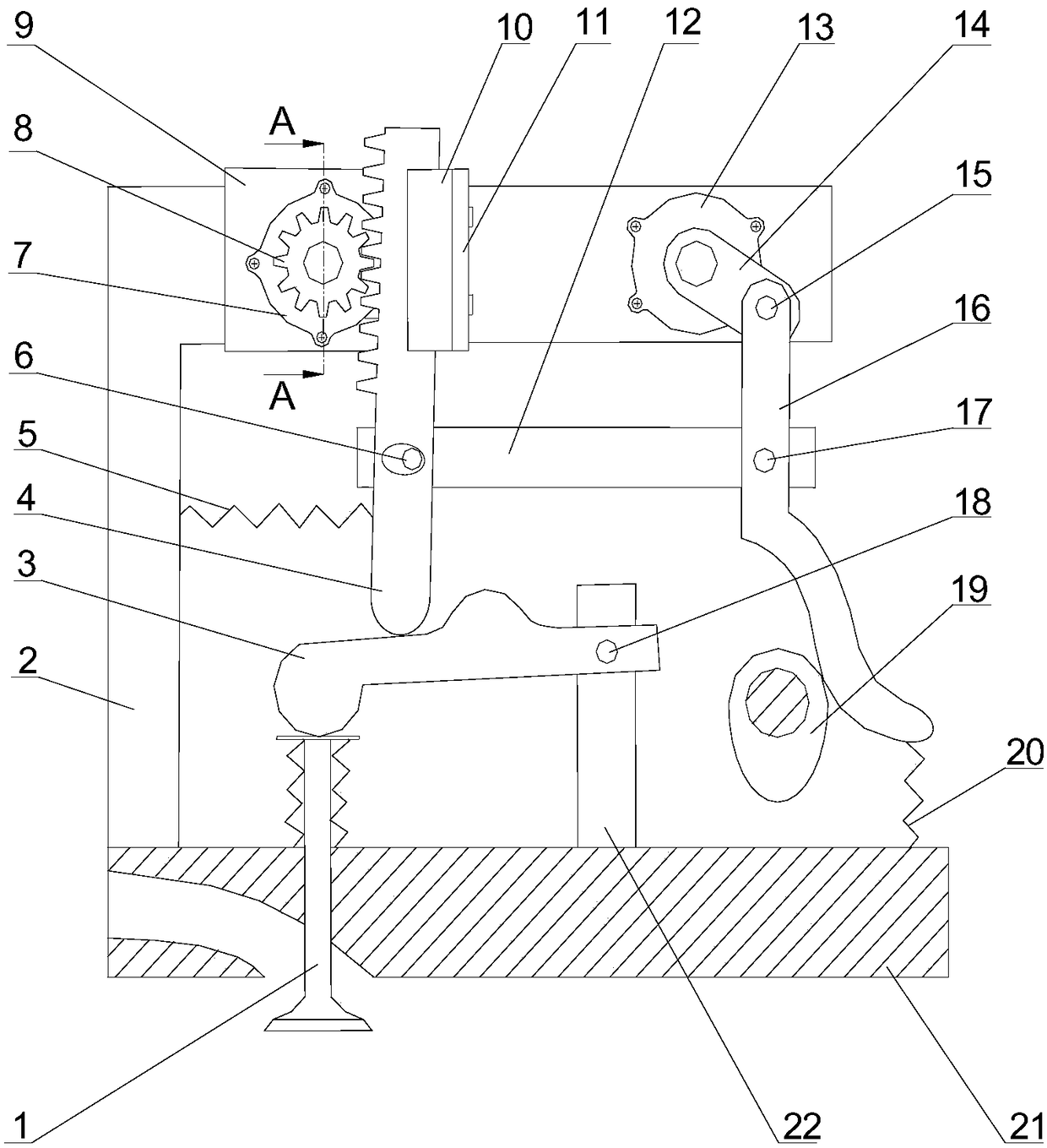

[0027] Attached below Figure 1-8 The present invention is described in detail:

[0028] refer to figure 1 , a valve timing-lift adjustment mechanism of the present invention comprises the following structures: valve (1), L-shaped bracket (2), swing arm (3), rack (4), return spring I (5) , pin a (6), stepping motor I (7), gear (8), connecting device (9), guide rail (10), connecting plate (11), connecting rod (12), stepping motor II (13) , rotating arm (14), pin b (15), hockey stick connecting rod (16), pin c (17), pin d (18), cam (19), return spring II (20), cylinder head (21) , swing arm support (22).

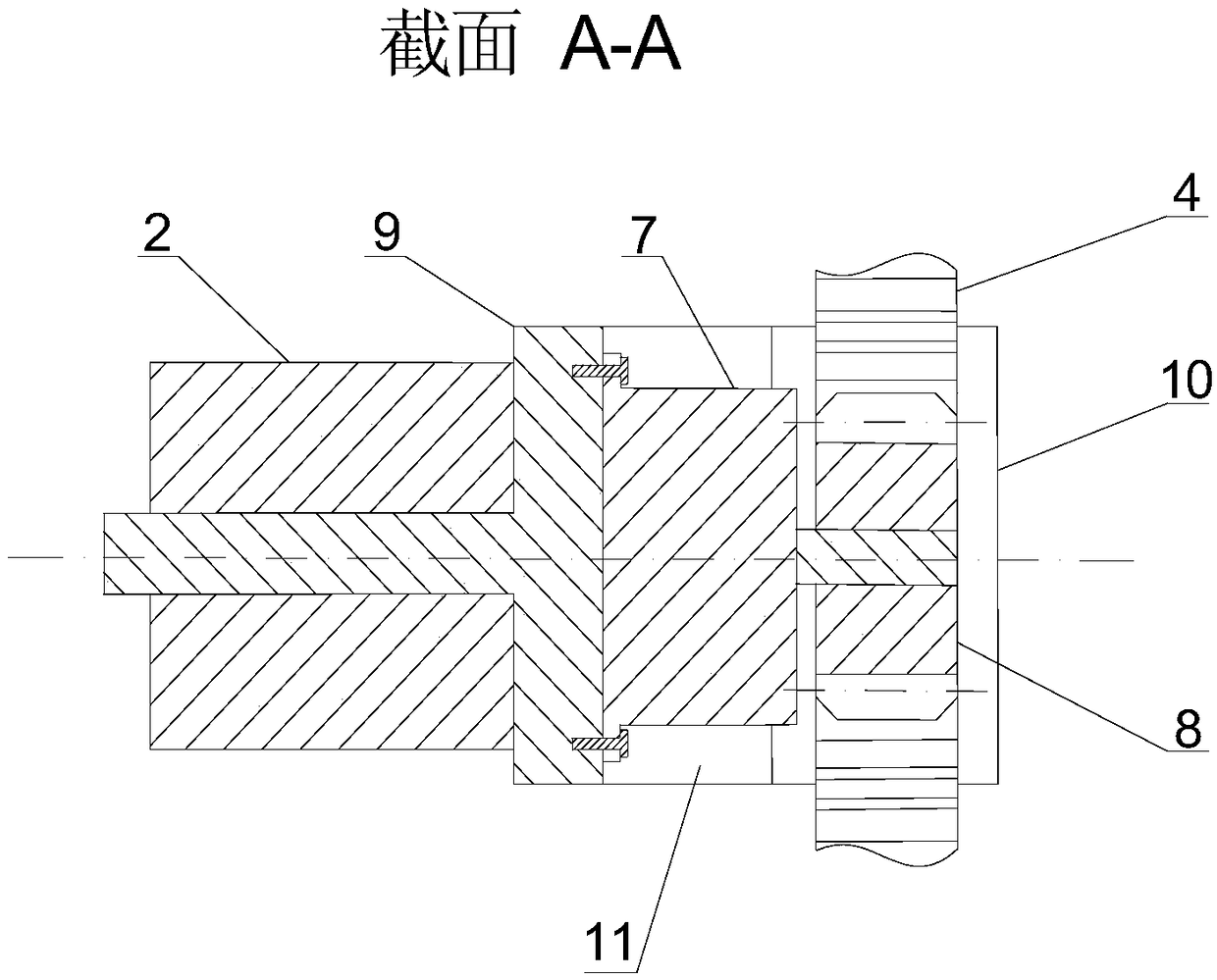

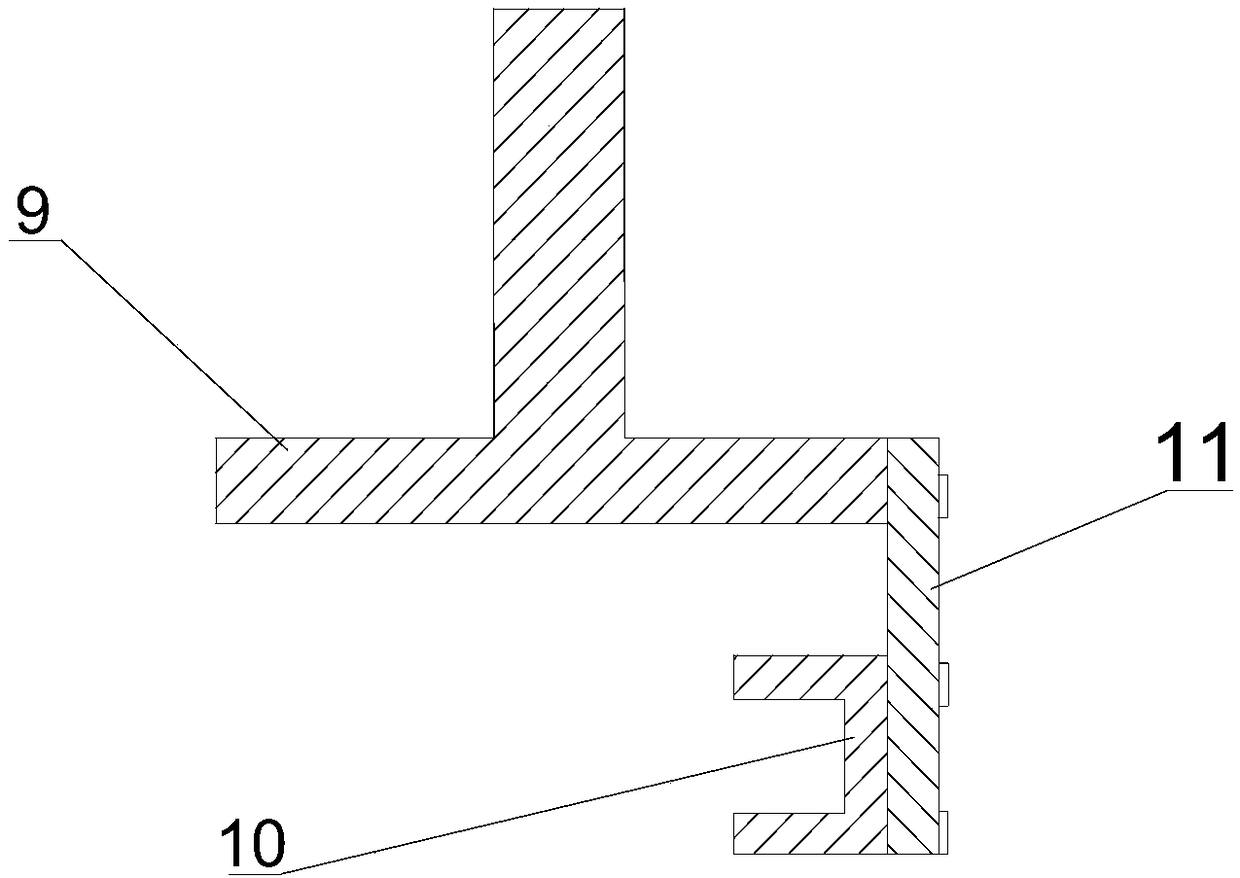

[0029] refer to figure 1 , figure 2 , Figure 4 , Figure 7 , the shaft (901) of the connecting device (9) is connected with the shaft hole (201) provided on the L-shaped bracket (2), and fits with its clearance, so that the connecting device (9) can rotate relative to the bracket (2); the rack ( 4) The upper part is placed between the guide rail (10) and the gear (8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com