Design Method of Adjusting Mechanism for tbcc Parallel Nozzles Embedded in Partition

A technology of nozzle adjustment and design method, which is applied to machines/engines, jet propulsion devices, etc., can solve the problems of occupation, large aircraft space, and long tail nozzles, and achieves compact space layout, simple structural design, and good thrust performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

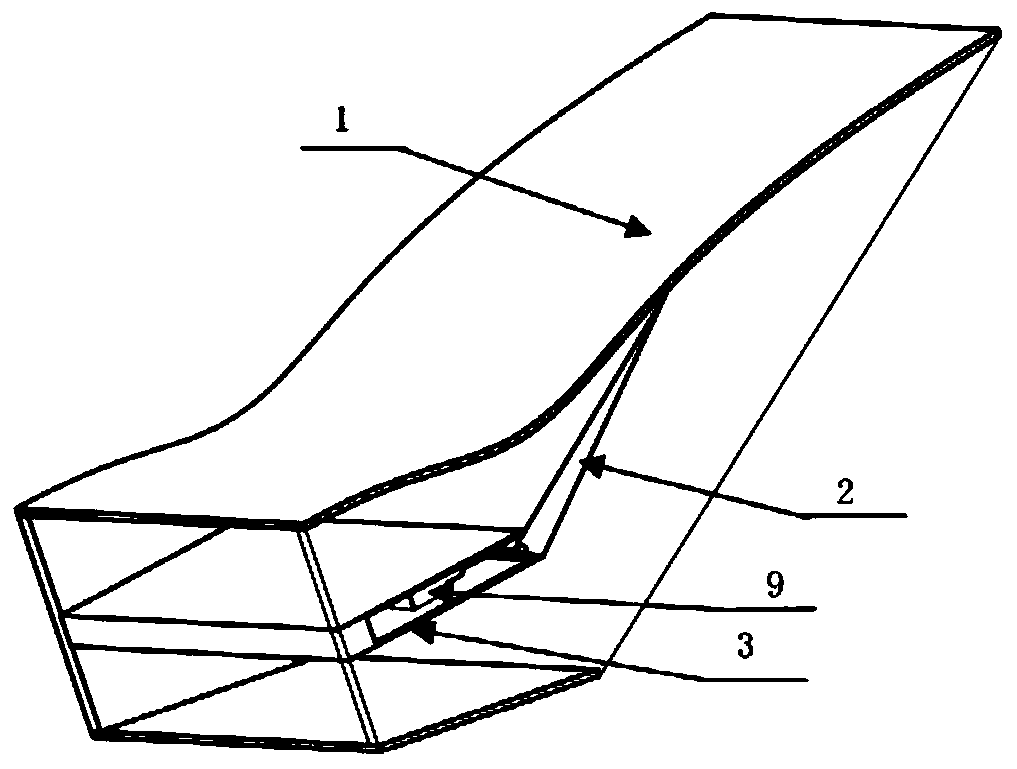

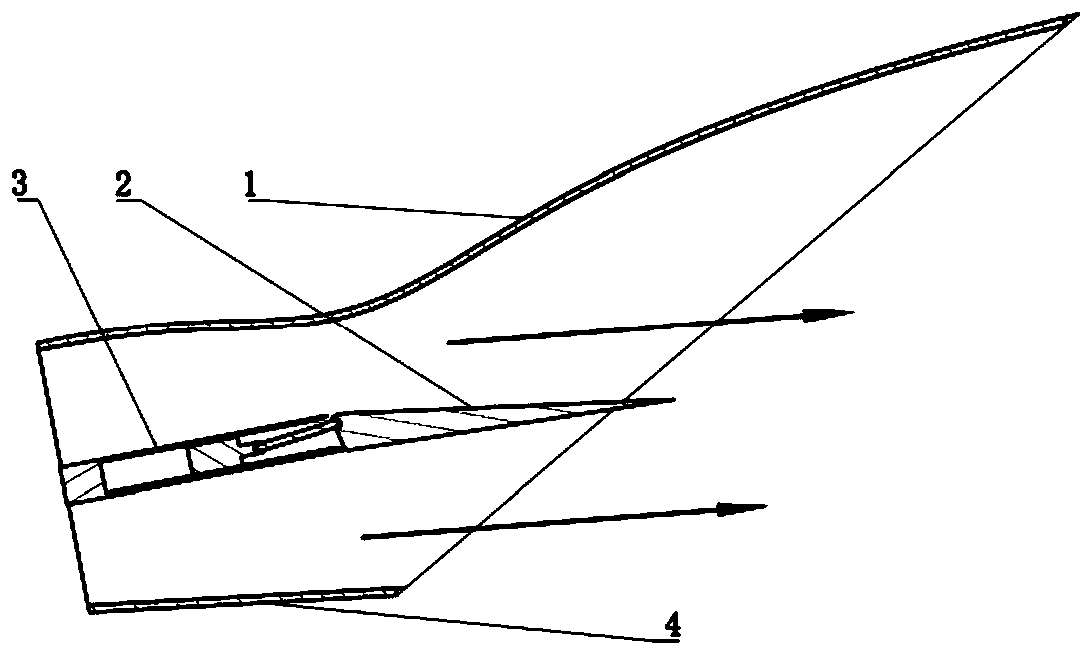

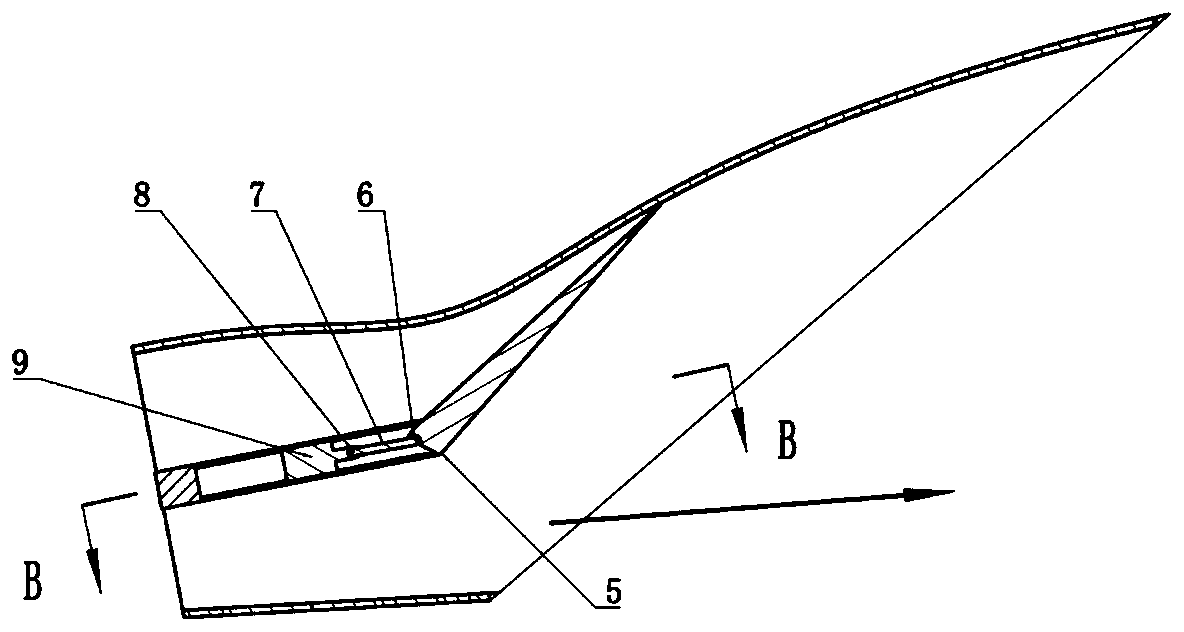

[0020] The TBCC tail nozzle involved in the present invention is a unilateral expansion parallel nozzle, such as figure 1 As shown, the upper passage is the tail nozzle of the turbine passage, and the lower passage is the tail nozzle of the ram passage. There are partitions and adjustment mechanisms between the passages. The adjustment plate of the adjustment mechanism is rotated to control the throat size and switch of the turbine passage. figure 2 with 3 They are two typical working states of TBCC combined engine tail nozzle. TBCC has multiple working states in the actual voyage. Parallel nozzles need to adapt to different outlet airflow states. By rotating the position of the adjustment plate, the maximum thrust performance can be obtained. TBCC As the flight Mach number increases, the upper channel of the parallel nozzle, that is, the throat of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com