Device and method for automatically searching unbalanced point position after vertical dynamic balance detection

An automatic search and detection technology, applied in the field of metal processing, can solve the problems that it is difficult for fine processing to meet the product accuracy requirements, affect the accurate results of the removal of unbalance, and the error of the unbalance position is large, so as to achieve fast search speed and reduce errors. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

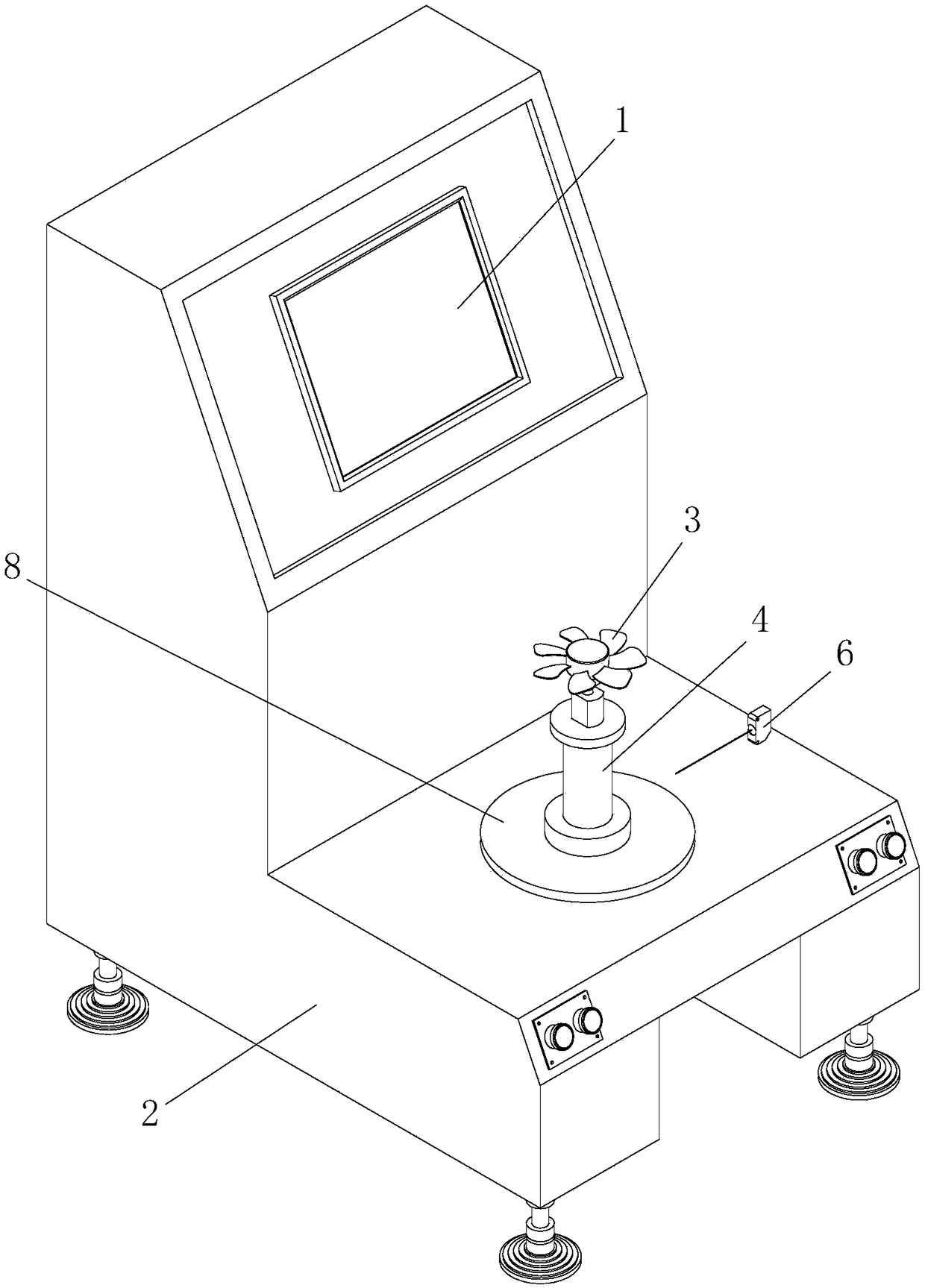

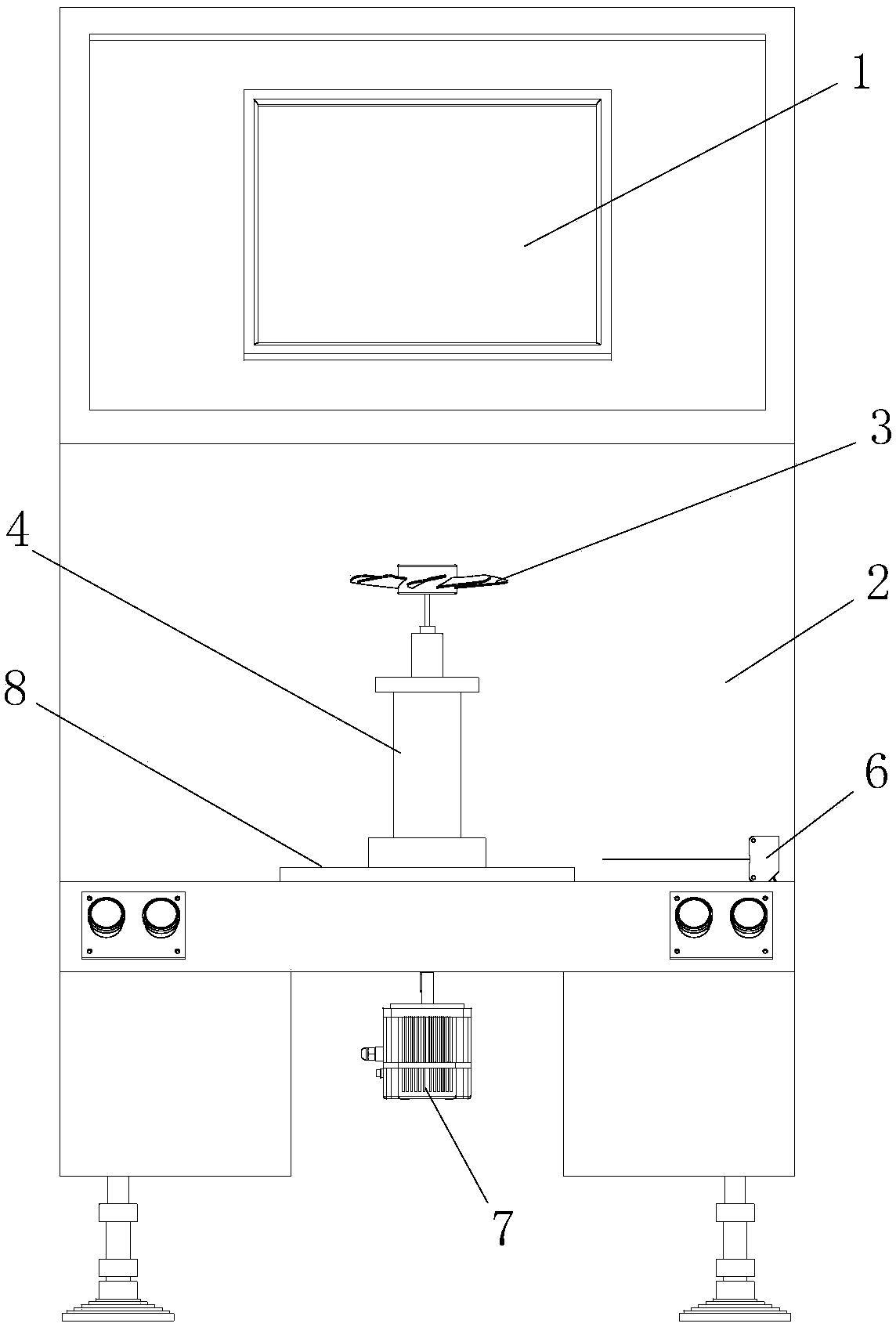

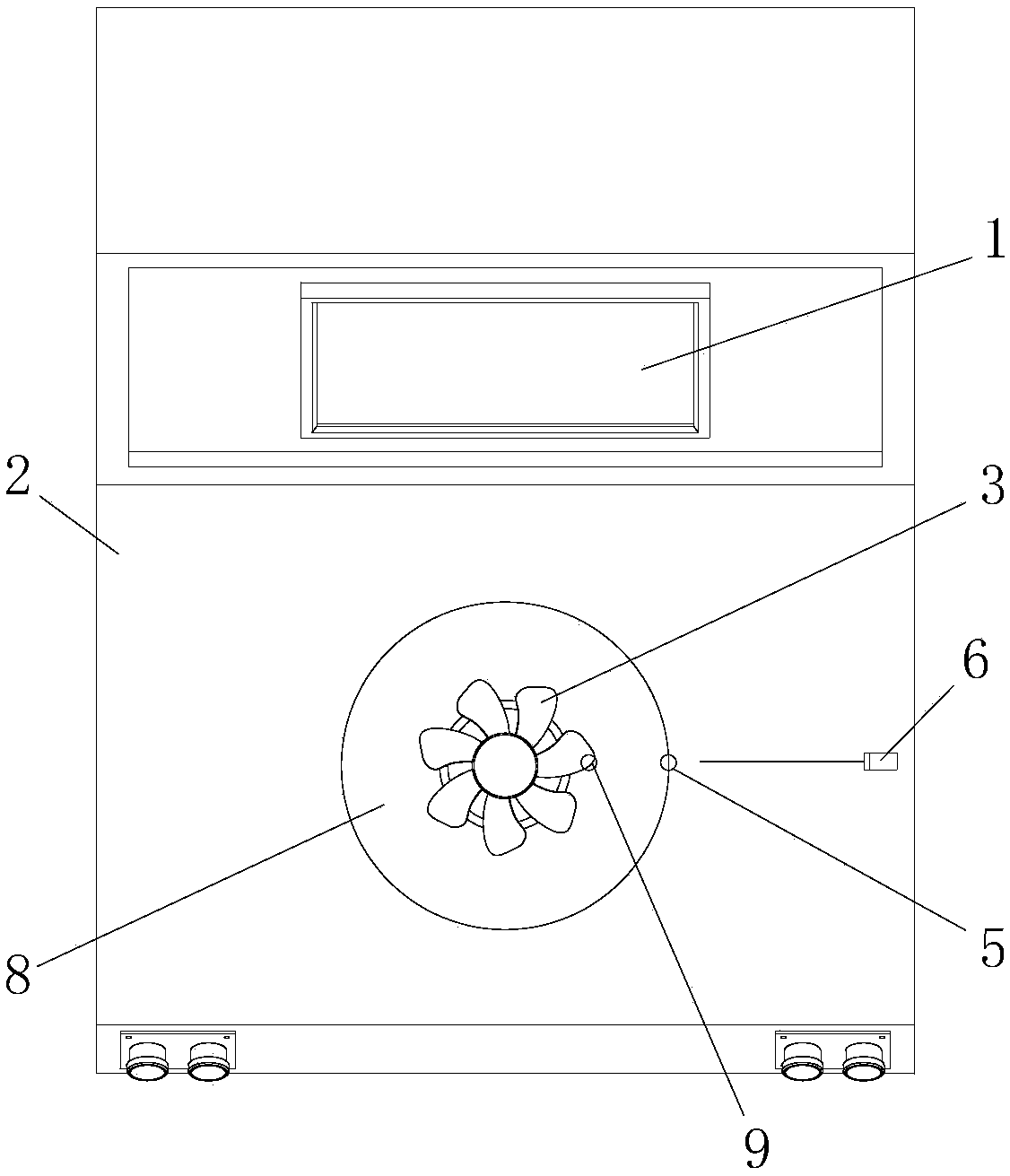

[0020] In this example, refer to figure 1 , figure 2 and image 3 , the device for automatically finding the position of the unbalanced point after the vertical dynamic balance detection includes a frame 2, an electric control system and a display system 1, and the display system 1 is installed on the frame 2 and connected to the electric control system. A 360-degree dial 8 is installed on the working table of 2, and a fixture 4 for fixing the workpiece 3 without driving is coaxially installed on the 360-degree dial 8. The fixture 4 and the 360-degree dial 8 are connected with a driving device to form a pair of two The rotating drive structure of the latter, the driving device is connected to the electric control system; a photoelectric sensor 6 is arranged beside the 360-degree dial 8, and the photoelectric sensor 6 faces the 360-degree dial 8.

[0021] The workpiece fixing position of the clamp 4 is set upward, and the workpiece 3 is horizontally fixed on the top of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com