Threaded-connection-device locking mechanism

A threaded connector and locking mechanism technology, which is applied in the direction of connection, clamping/spring connection, parts of the connecting device, etc., can solve the problem of low locking reliability of the threaded connector, and achieve low cost and high reliability , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

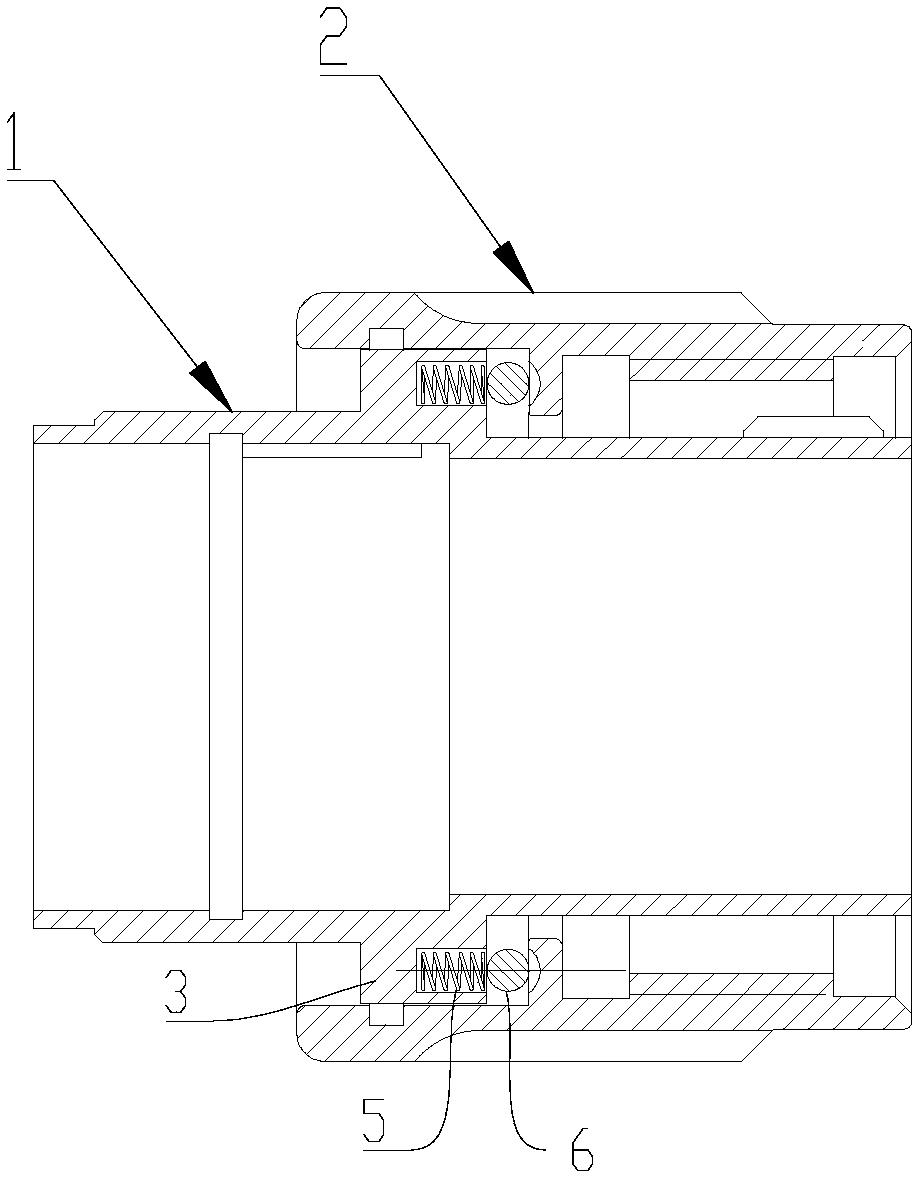

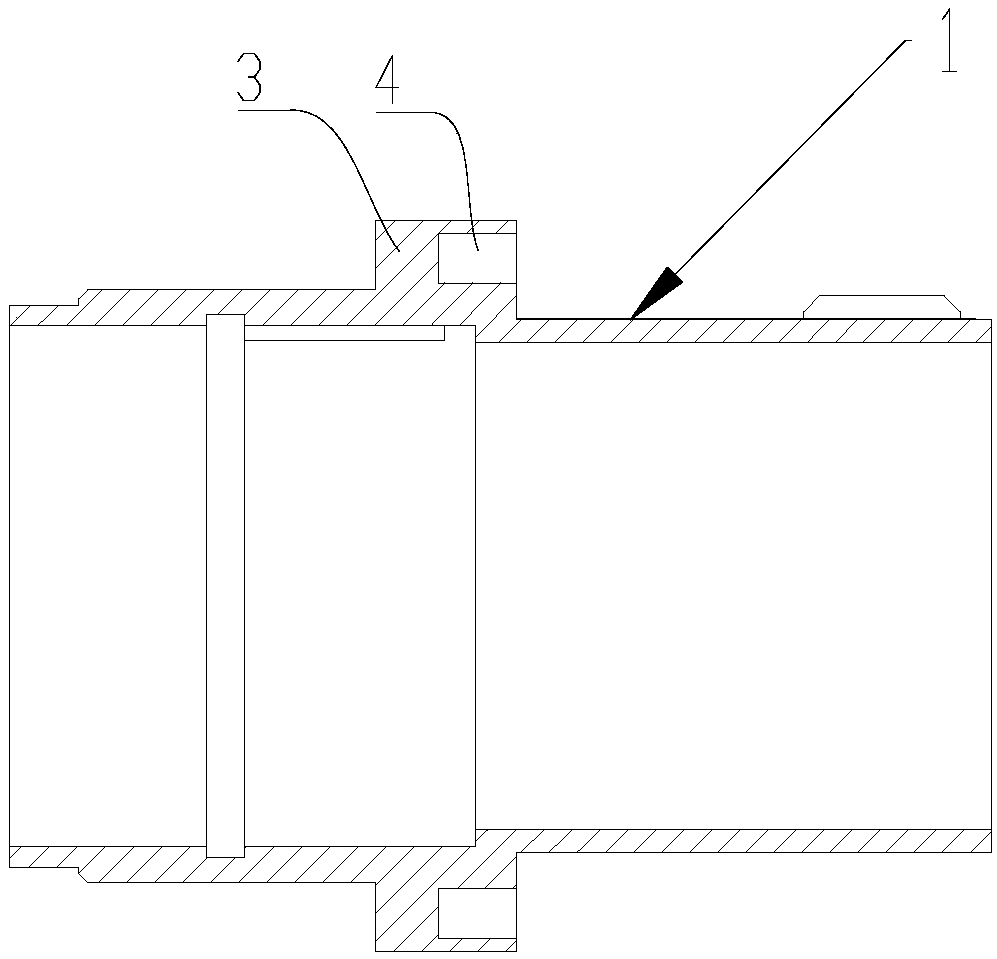

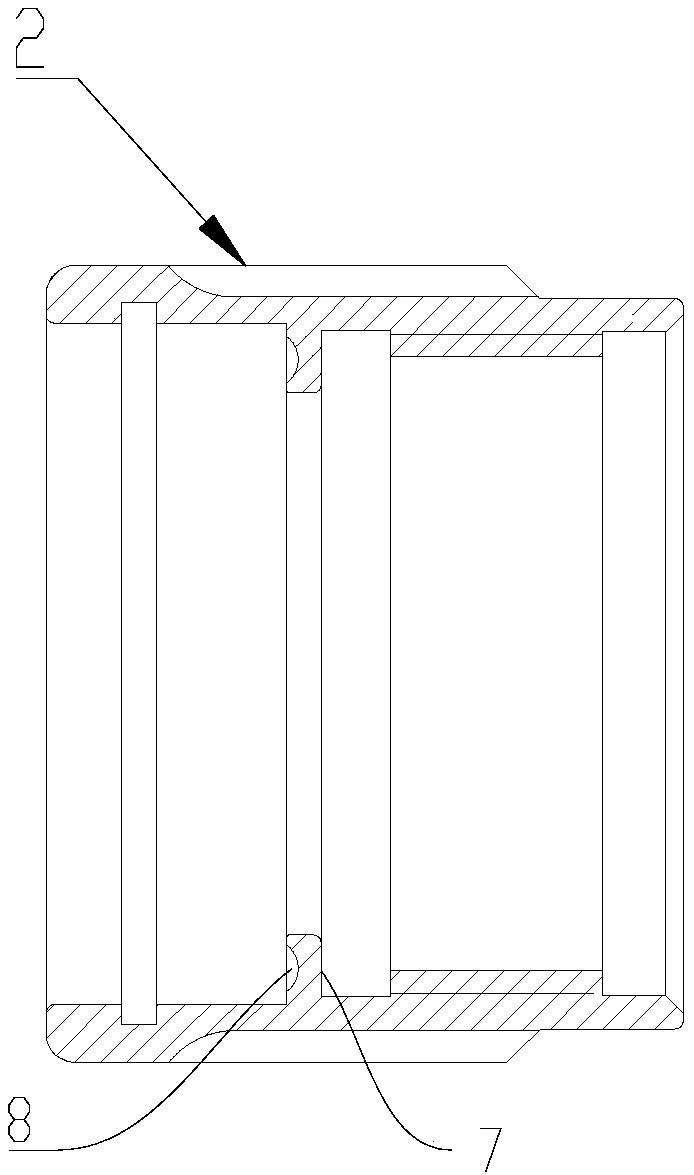

[0014] As attached in the manual Figure 1 to Figure 2 The threaded connector locking mechanism shown includes a plug housing 1 and a connecting cap 2, a first protrusion 3 is provided in the middle of the outer side of the plug housing 1, and a round groove 4 is opened on the right side of the first protrusion 3, A spring 5 is arranged in the circular groove 4, a marble 6 is connected to the right side of the spring 5, a second bump 7 is arranged on the inner side of the connecting cap 2, and a ball pit 8 is uniformly arranged on the left side of the second bump 7, and the number of the ball pit 8 is And diameter is identical with marble 6.

[0015] The outer side of the plug housing 1 is threadedly connected with the inner side of the connecting cap 2 .

[0016] The marble 6 and the spring 5 are made of stainless steel.

[0017] In the actual working process, as the connecting cap 2 and the plug housing 1 are continuously tightened, the pin 6 jumps in the ball pit 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com