Construction method for vertically laying super-high-rise building cable

A vertical laying and construction method technology, applied in the direction of cable laying equipment, etc., can solve the problems of inability to control the cable angle, and achieve the effect of improving construction quality, ensuring quality, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

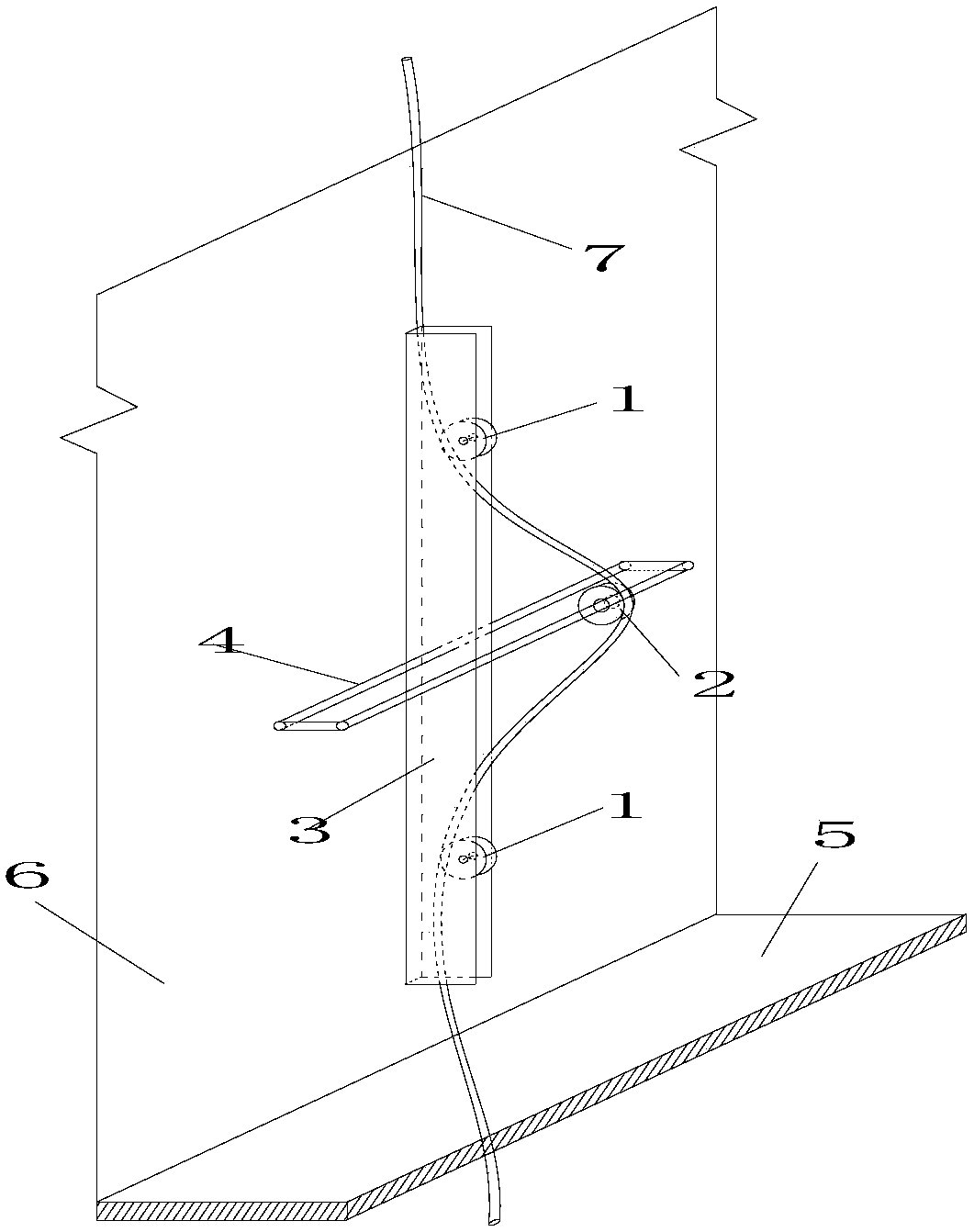

[0027] The project has six floors in the basement and 52 floors above the ground. The substation and power distribution room are located on the first floor of the basement. The power cables of this project are distributed to the distribution boxes on each floor through the laying of electric wells. The cables are heavy and too long. In order to ensure the construction quality, the construction method of laying cables vertically in super high-rise buildings is adopted.

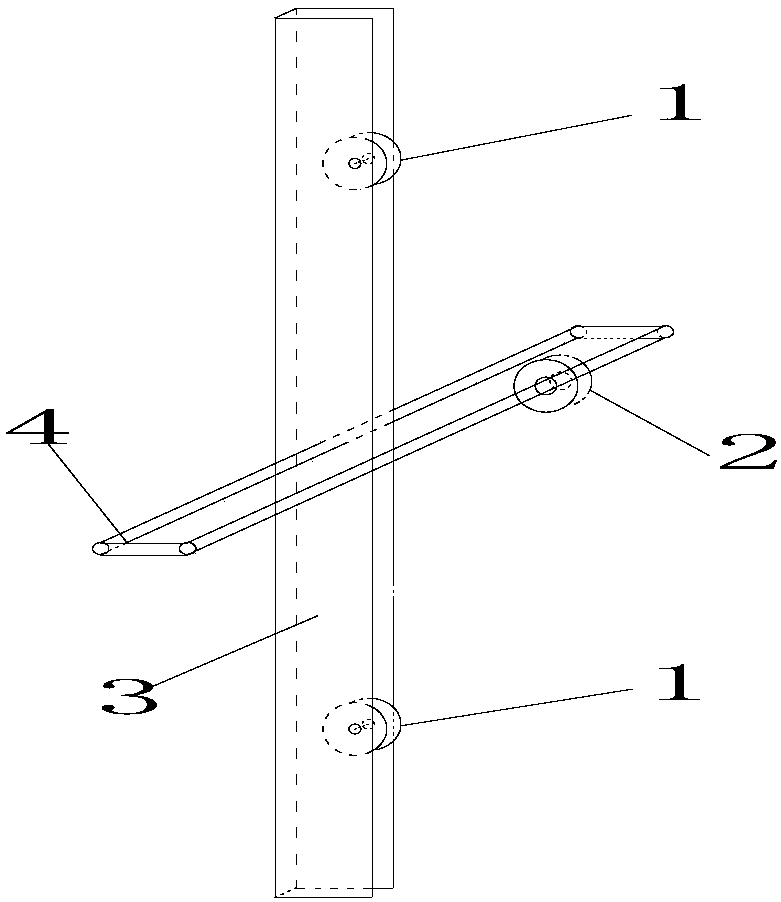

[0028] (1) Install a cable reducer every 3 floors on the building structure 6 close to the cable bridge along the cable lowering direction. Described cable speed reducer comprises the channel steel 3 that is arranged vertically, and described channel steel is fixed on the building structure, between the left flange plate and the right flange plate of described channel steel 3 The upper part and the lower part are respectively connected with a fixed pulley 1 by bolts arranged in the horizontal direction, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com