Heat collecting end and heat radiating device

A technology of heat collection end and heat dissipation device, which is applied in cooling/ventilation/heating transformation, instruments, electrical and digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present application clearer, the heat collecting end and the cooling device of the present application will be further described in detail through the following embodiments and in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

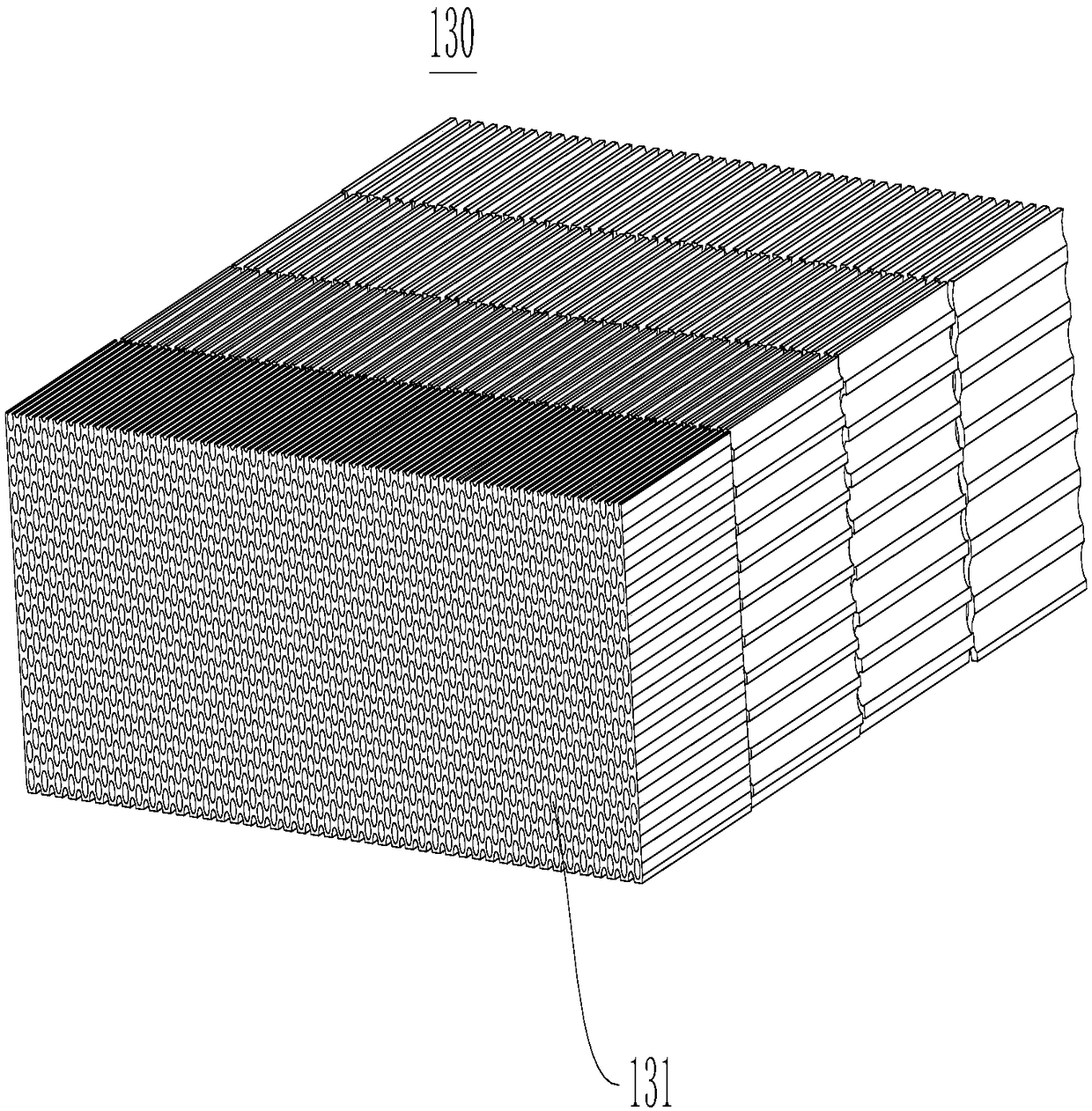

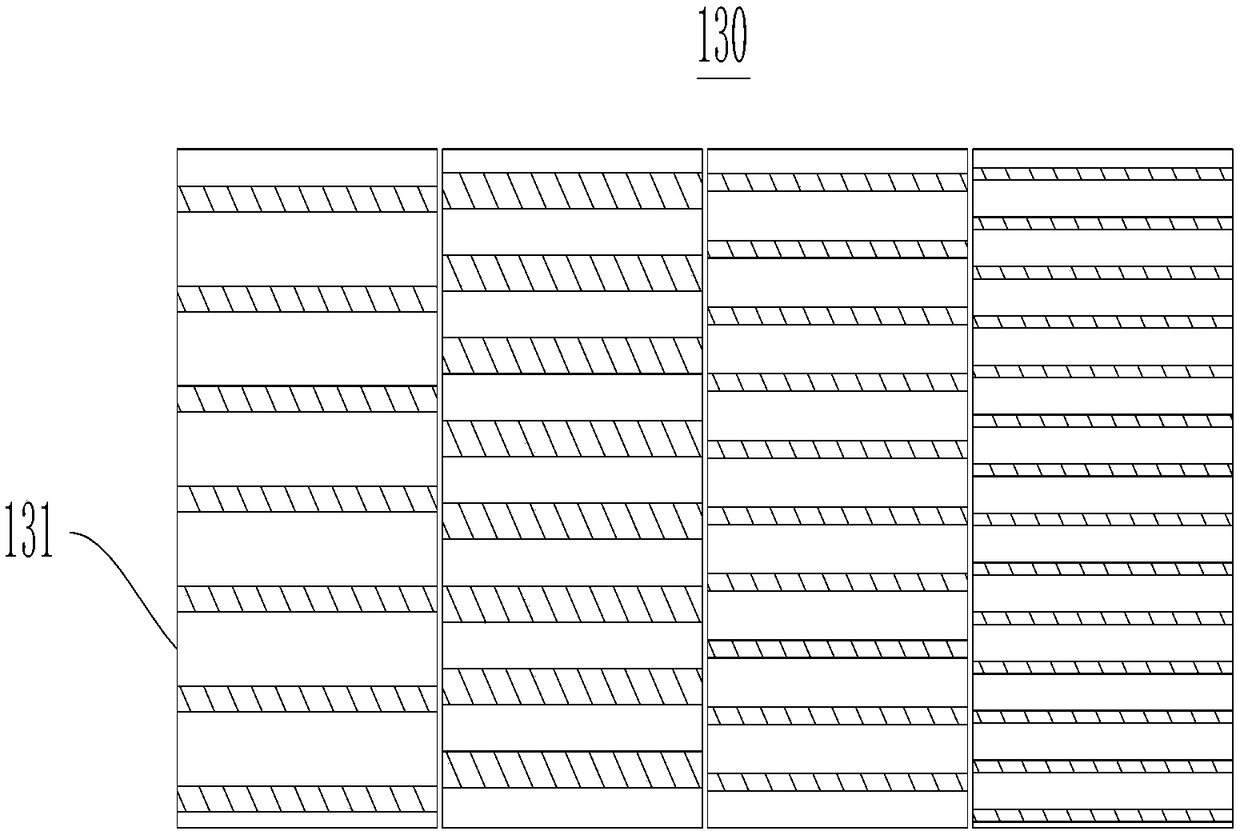

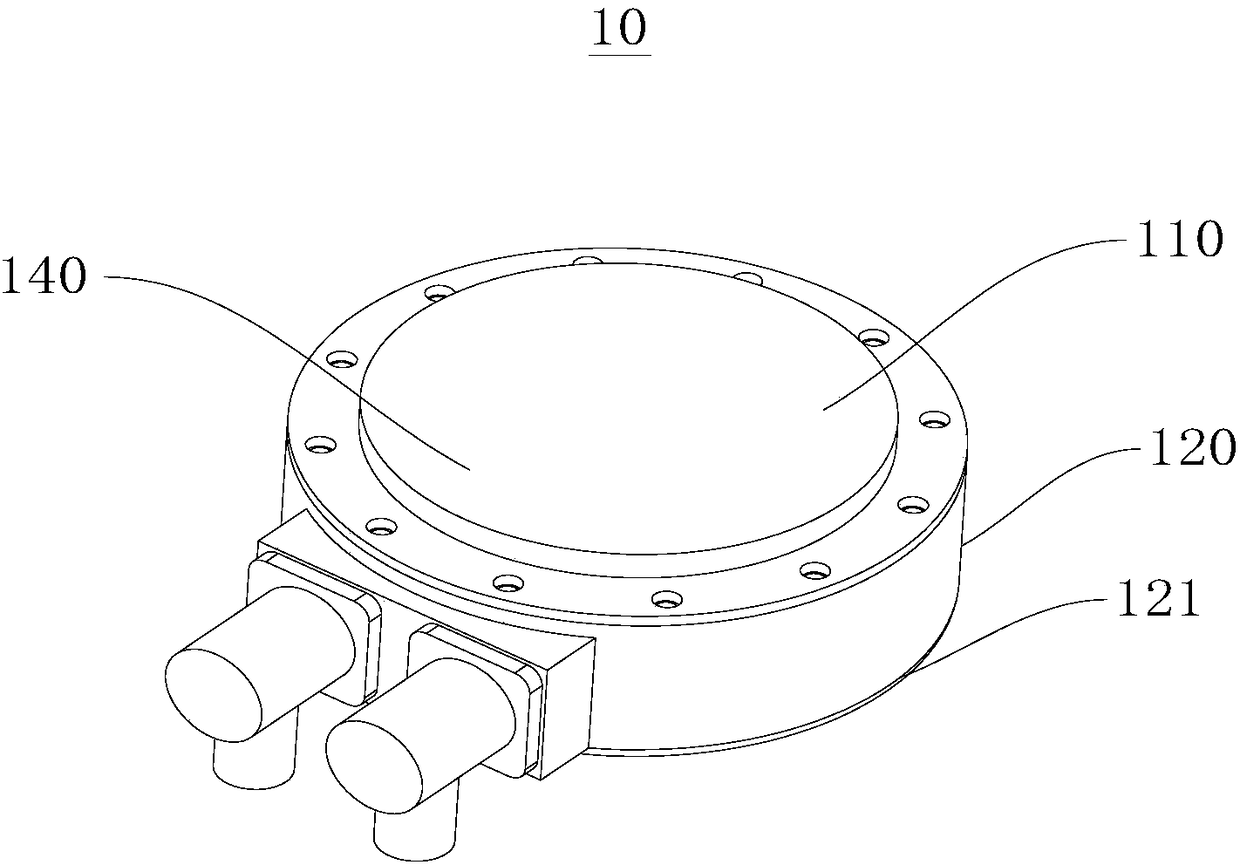

[0027] Please see attached Figure 1-3 , the present application provides a heat collection end 10 , and the heat collection end 10 includes at least two microchannel modules 130 . The at least two microchannel modules 130 have channels 131 extending along a first direction. The at least two microchannel modules 130 are arranged at intervals along the first direction. The pore diameter of the microchannel module 131 is 0 micron-1000 micron. The pore diameters of the channels 131 of the microchannel module 130 gradually de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com