Design method and control method for electronic cigarettes and electronic cigarette

A technology of design method and control method, which is applied in the field of electronic cigarettes, can solve the problems of complex design process, low production efficiency, and low production cost, and achieve the effects of easy manufacturing, high production efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

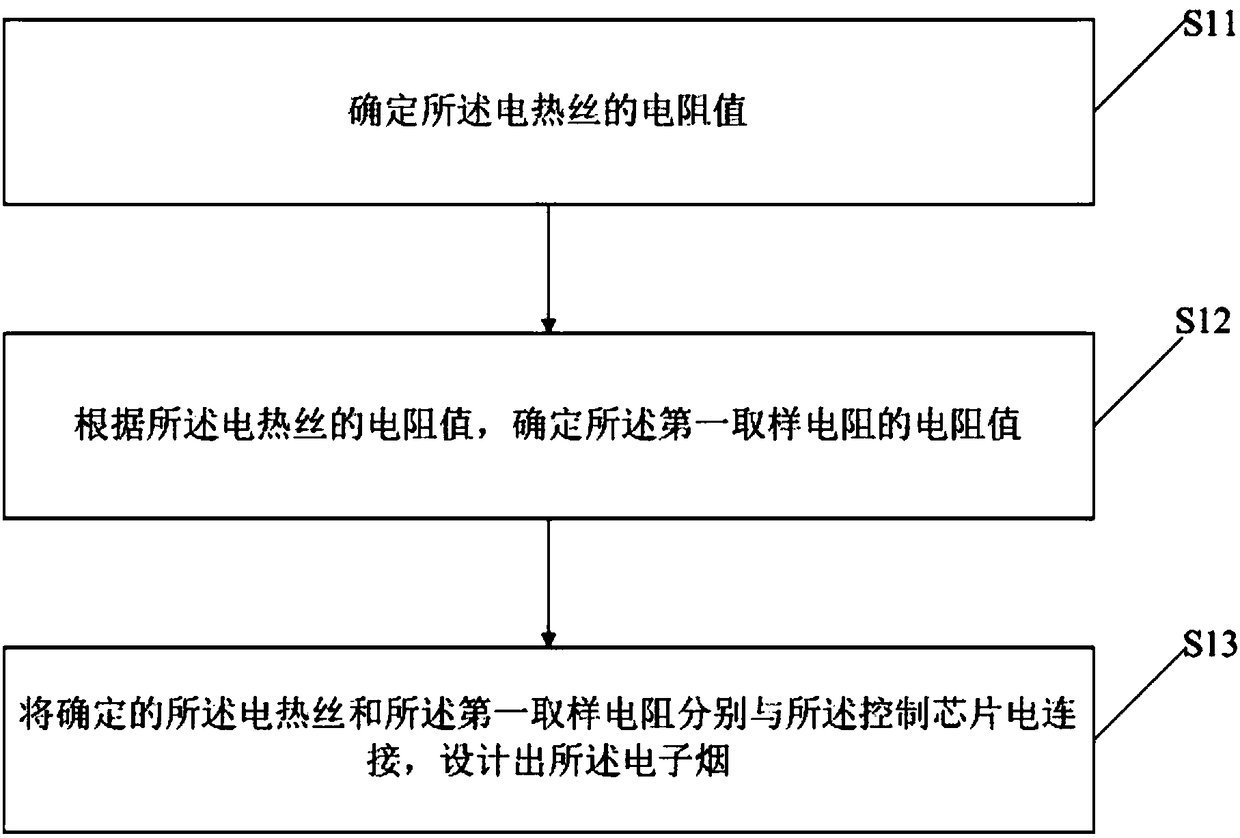

[0037] Please refer to figure 1 , an embodiment of the present invention provides a design method for an electronic cigarette, the electronic cigarette includes a heating wire, a first sampling resistor and a control chip, the heating wire is used to atomize e-liquid to form smoke, and the control chip is used to When the electronic cigarette starts to work, the current of the heating wire is controlled according to the resistance value of the first sampling resistor, and the design method includes the following steps:

[0038] S11. Determine the resistance value of the heating wire;

[0039] S12. Determine the resistance value of the first sampling resistor according to the resistance value of the heating wire;

[0040] S13. Electrically connect the determined heating wire and the first sampling resistor to the control chip respectively, and design the electronic cigarette.

[0041]It should be noted that the main circuits of the electronic cigarette, such as the charging m...

Embodiment 2

[0065] Based on the same inventive concept, please refer to figure 2 and Figure 5 , the present invention also provides a method for controlling an electronic cigarette, the electronic cigarette includes a heating wire, a first sampling resistor and a control chip, the heating wire is used to atomize e-liquid to form smoke, and the resistance of the heating wire is Change with temperature, the first sampling resistor is electrically connected to the control chip;

[0066] The control methods include:

[0067] S21. The control chip controls the current of the heating wire when the electronic cigarette starts to work according to the resistance value of the first sampling resistor;

[0068] S22. The control chip detects the actual resistance value of the heating wire in actual work, and controls the current flowing through the heating wire according to the actual resistance value, so that the working temperature of the electronic cigarette is controlled at a preset value with...

Embodiment 3

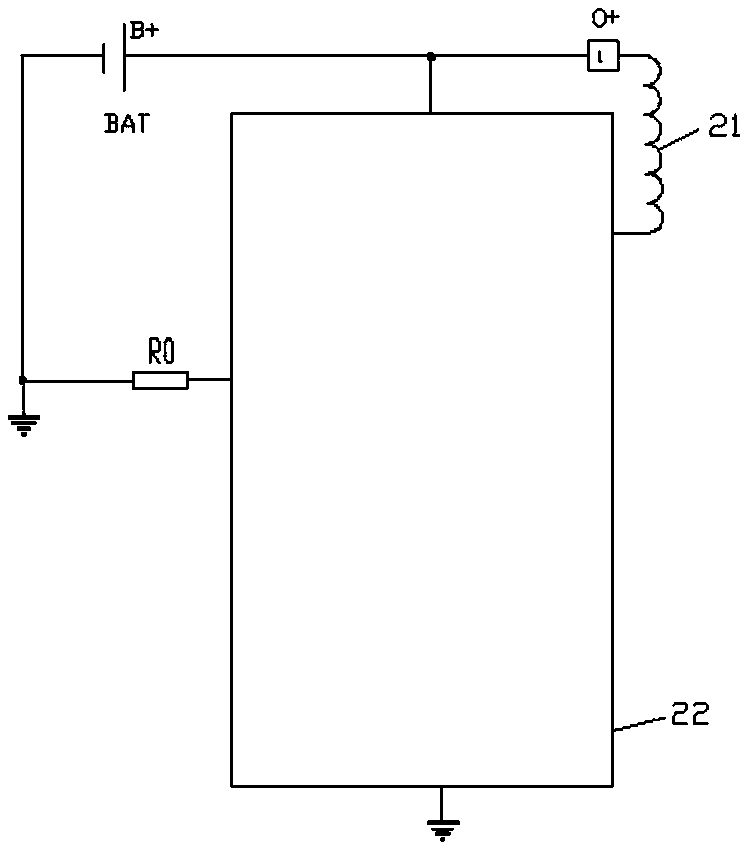

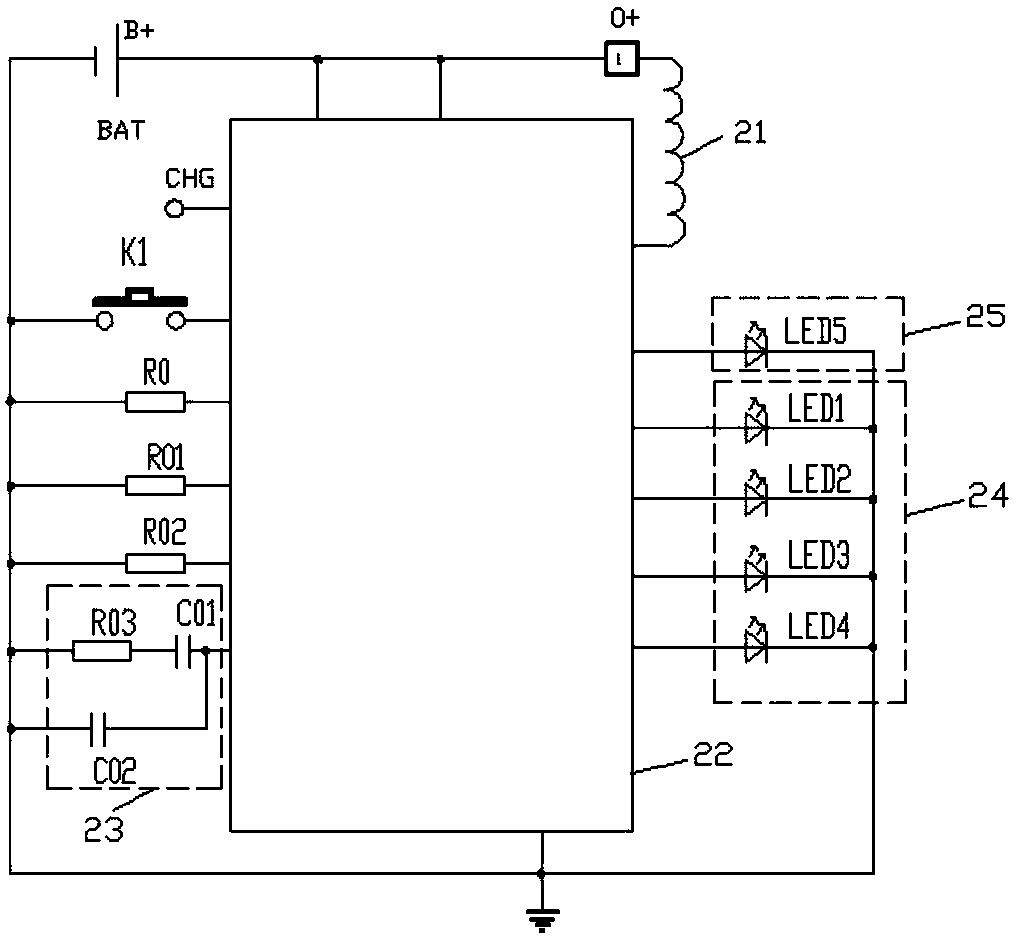

[0084] Based on the same inventive concept, please refer to figure 2 , the present invention also provides an electronic cigarette, including a heating wire 21, a first sampling resistor R0 and a control chip 22;

[0085] The heating wire 21 is electrically connected to the control chip and is used to atomize e-liquid to form smoke, and the control chip 22 is used to control the heating wire 21 when the electronic cigarette starts to work according to the resistance value of the first sampling resistor R0 current. Specifically, in this embodiment, one end of the first sampling resistor R0 is grounded, and the other end of the first sampling resistor R0 is only electrically connected to the input pin of the control chip 22 . It can be understood that the first sampling resistor R0 can also be set as a pull-up resistor, that is, one end of the first sampling resistor R0 is electrically connected to the positive pole B+ of the power supply, and the other end of the first sampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com