Hydraulic start and stop system of double rotor hammer crusher

A hammer crusher and double-rotor technology, applied in the direction of power control mechanism, wing leaf control mechanism, door/window fittings, etc., can solve maintenance difficulties, heavy crusher inspection door, and fine material leakage from the gap of the sieve plate Inferior problems to achieve the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

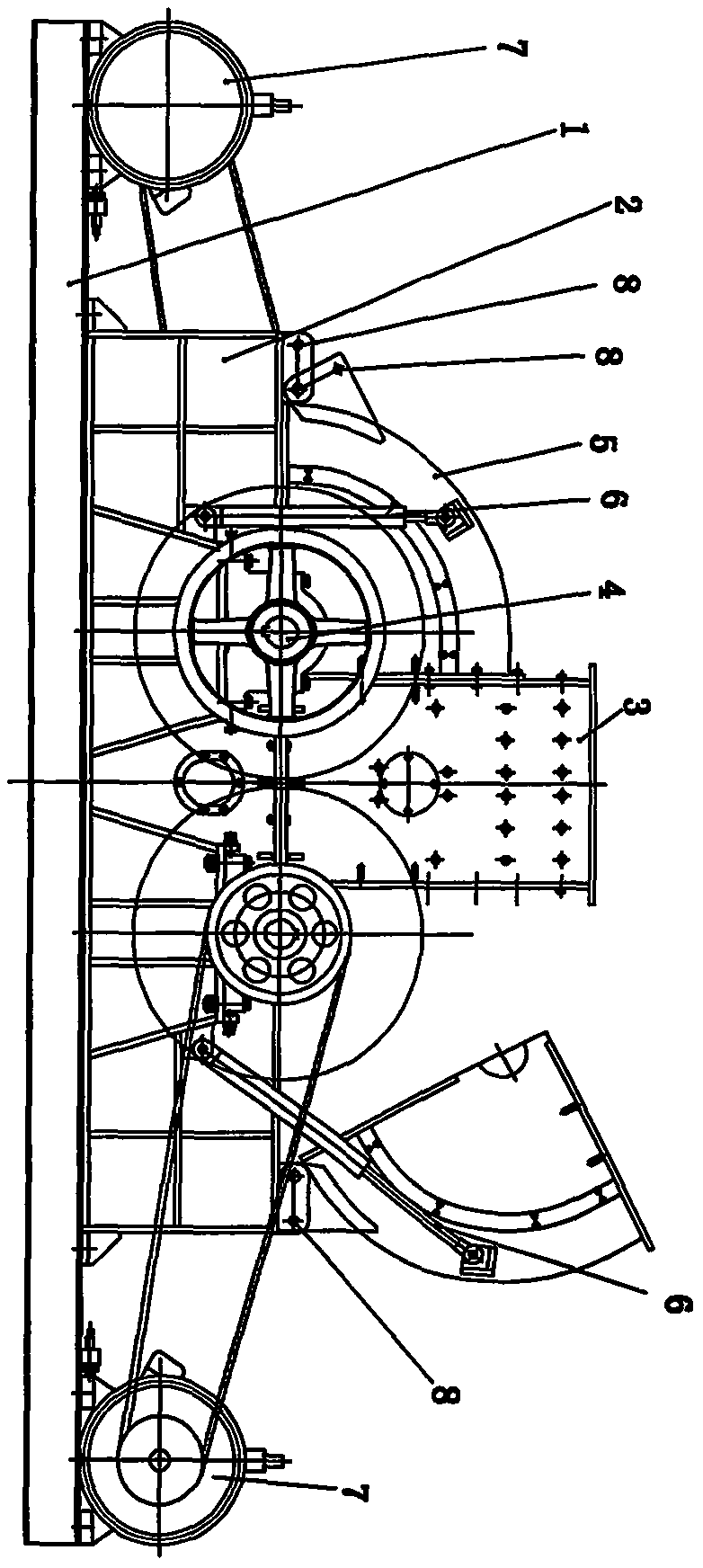

[0011] Such as figure 1 The hydraulic opening and closing system of the double-rotor hammer crusher shown has a machine base 1, a lower box 2 is arranged on the machine base 1, and a blanking box 3 is fixed on the upper part of the middle position of the lower box 2, and the blanking box 3 It is an axis of symmetry, and rotors 4 are symmetrically arranged on the lower box 2 from the middle to the outside. The upper cover of the rotor 4 is provided with an inspection door 5, and the inspection door 5 is hinged with the lower box 2. The gap between the inspection door 5 and the lower box 2 A hydraulic opening and closing system 6 is provided, and motors 7 are respectively provided on both sides of the machine base 1, and the motor 7 drives the rotor 4 to work. The inspection door 5 and the lower box body 2 are respectively provided with safety pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com