Gas power device for part cleaning machine

A technology of gas power and cleaning machine, which is applied in the direction of liquid cleaning method, cleaning method and utensils, chemical instruments and methods, etc. It can solve the problems of increasing transmission distance, economic loss, hidden danger of motor safety, etc., and achieves a high degree of integration , unified power source, good braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

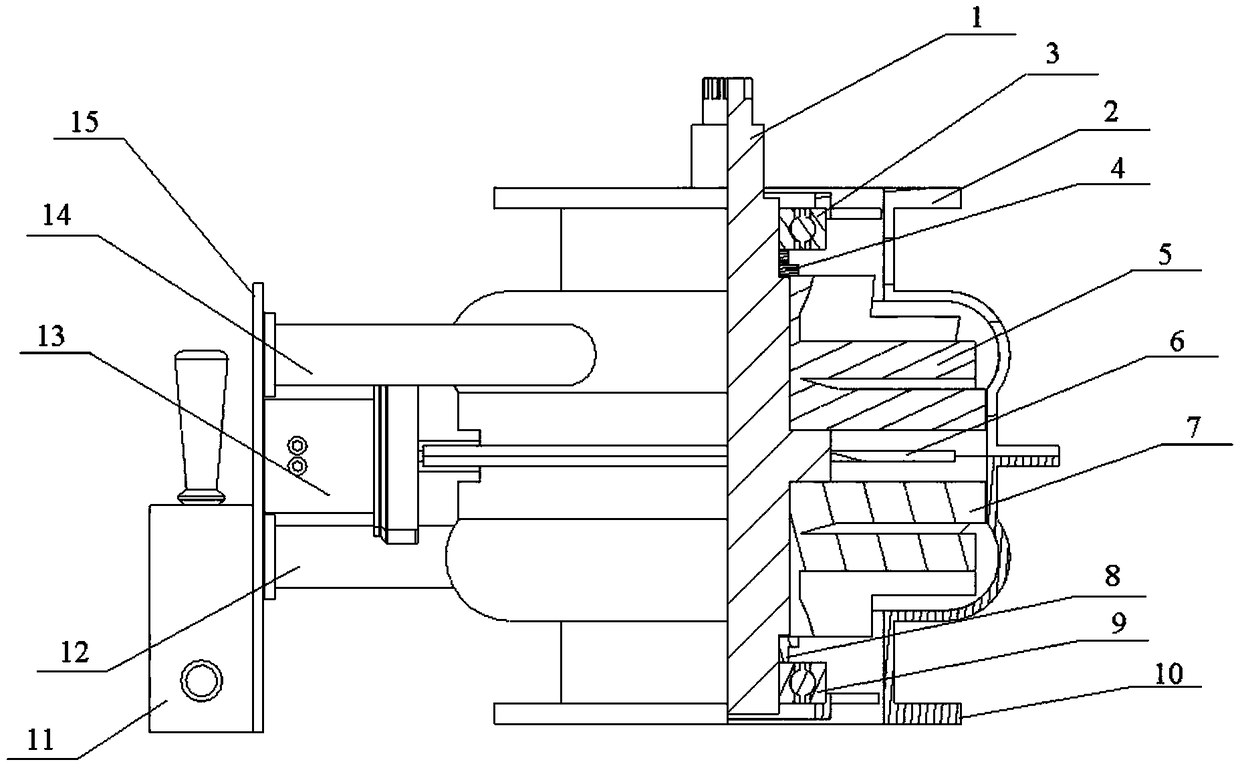

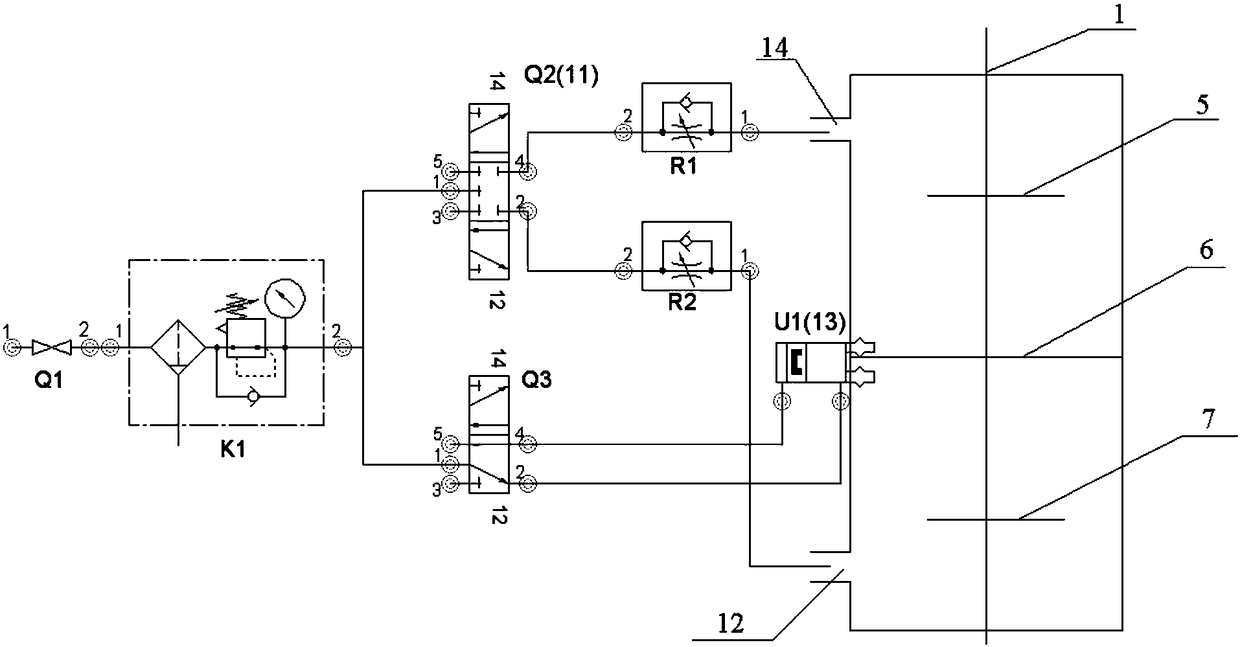

[0024] Such as Figure 1-2 As shown, a gas power device for a parts cleaning machine includes an upper air guide shell 2 and a lower air guide shell 10 with the same structure and relatively connected; the upper air guide shell 2 and the lower air guide shell 10 constitute the device housing; The rotating shaft 1 is arranged in the device housing, and the upper end protrudes from the upper end of the upper wind guide shell 2 to connect to the parts cleaning machine; it also includes an upper impeller 5 and a lower impeller 7 arranged on the rotating shaft 10 with opposite installation directions; the upper impeller 5 is arranged on the upper In the air guide shell 2, the lower impeller 7 is arranged in the lower air guide shell 10; the upper air guide shell 2 is connected to the upper air inlet 14, and the lower air guide shell 10 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com