Valve opening device for uranium hexafluoride pressure heating tank

A uranium hexafluoride, opening device technology, applied in valve device, valve operation/release device, valve details, etc., can solve the problem of the long time required for the pressure and temperature to drop to a safe value, the inability to close the angle valve in time, etc. problem, to achieve the effect of light and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

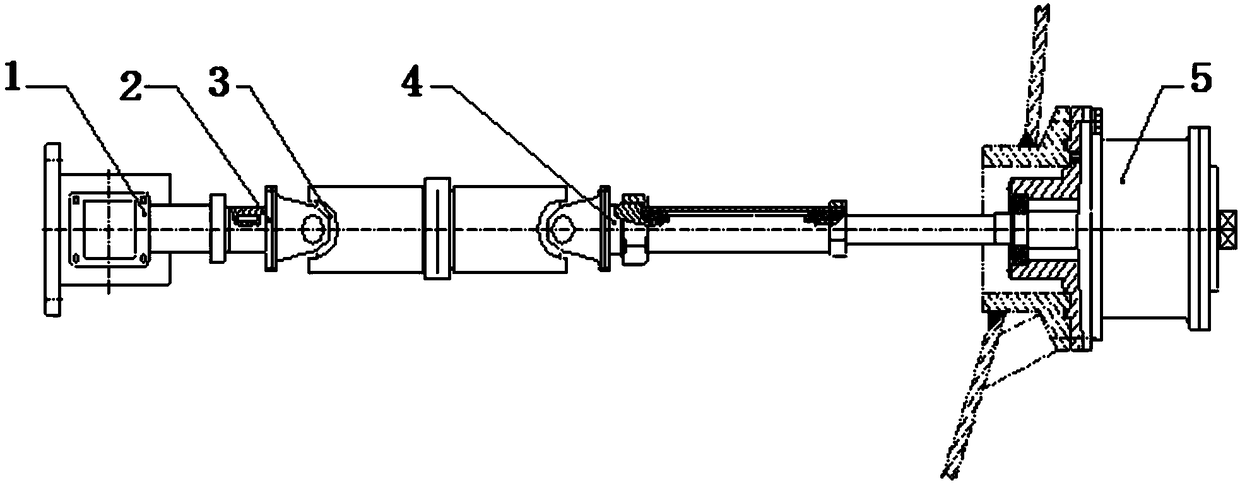

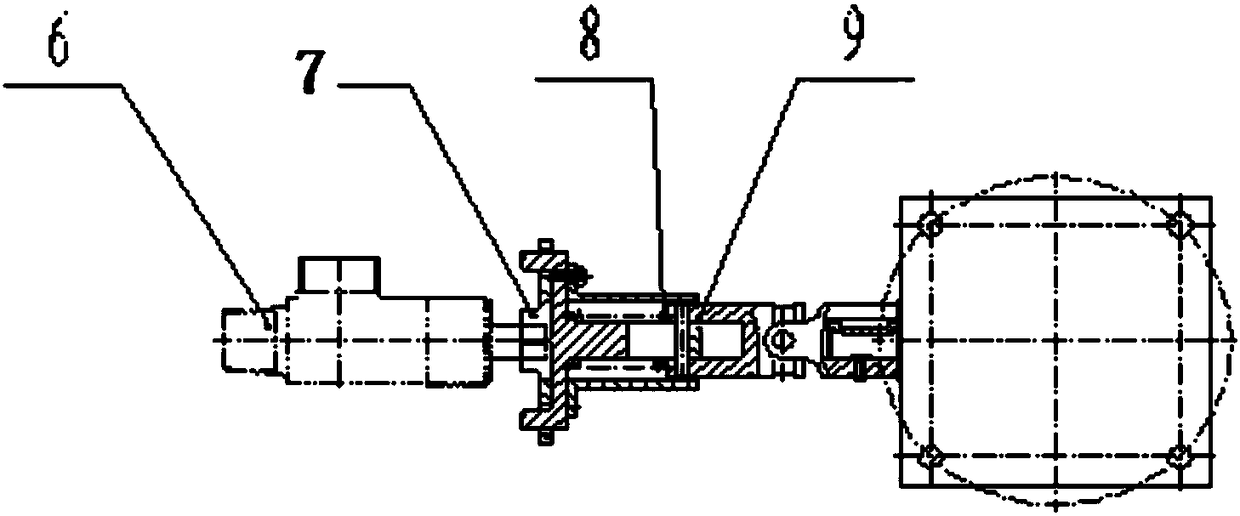

[0018] like figure 1 As shown in -2, the valve opening device for UF6 autoclave according to the present invention includes a rotary box 1, a left connecting shaft 2, a cross shaft type universal coupling 3, a right connecting shaft 4, and a magnetic coupling Device 5, valve 6, valve opening disc 7, spring 8, cross shaft universal joint 9; the output shaft of the rotating box 1 is connected to the left connecting shaft 2, cross shaft type universal coupling 3, right connecting shaft 4, magnetic The shaft coupling 5 and the cross shaft universal joint 9 are connected with the rotating box 1, and a spring 8 is arranged between the valve opening disc 7 and the cross shaft universal joint 9, and the valve opening disc 7 is centeredly connected with the valve stem of the valve 6 .

[0019] The device is driven by magnetic force, and the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com