Sand drying device for building

A drying device and a technology for building sand, applied in the field of construction engineering, can solve the problems of low drying efficiency and uneven heating, and achieve the effects of saving time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

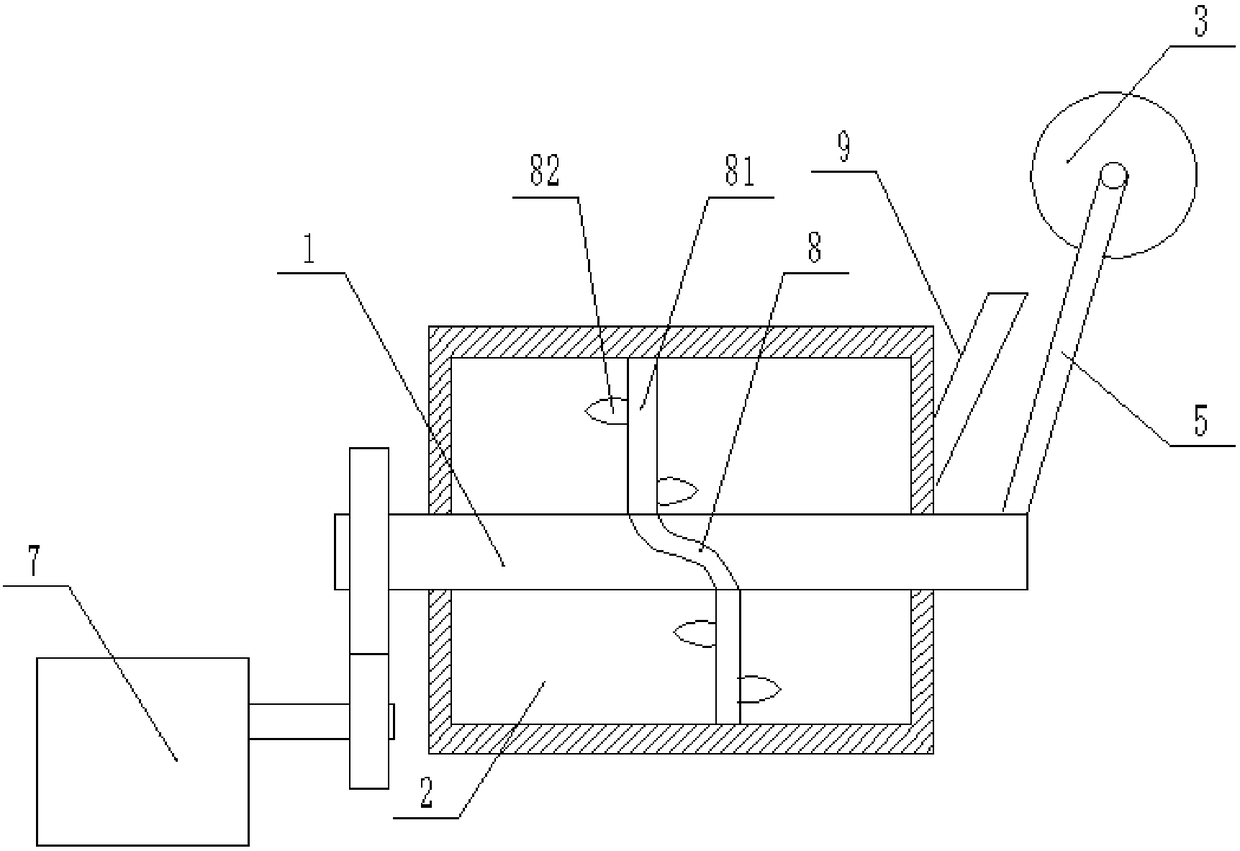

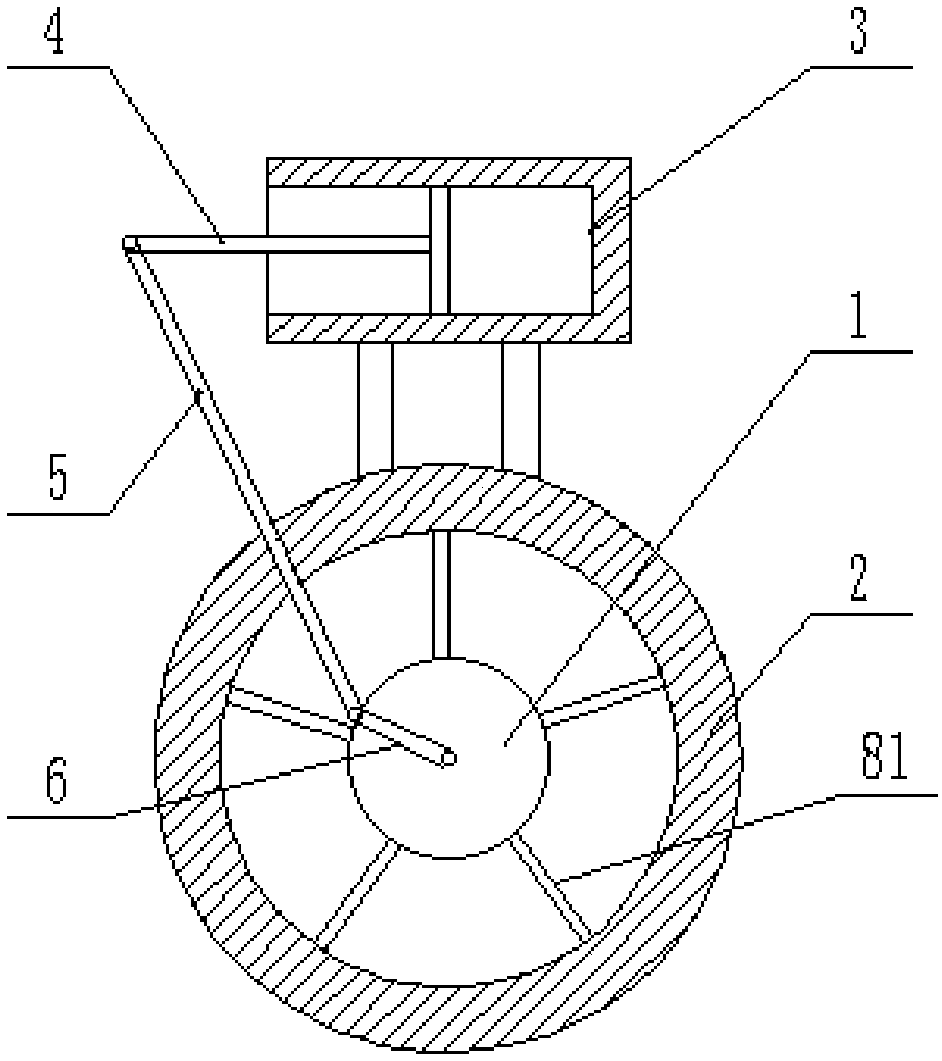

[0020] The reference signs in the drawings of the description include: rotating shaft 1, drying cylinder 2, piston barrel 3, piston rod 4, first connecting rod 5, second connecting rod 6, rotating motor 7, spiral groove 8, column rod 81, Stirring blade 82, delivery pipe 9.

[0021] Such as figure 1 As shown, the sand drying device for construction includes a frame on which a piston barrel 3 and a drying cylinder 2 located below the piston barrel 3 are arranged. The middle parts of the left and right ends of the drying cylinder 2 are provided with mounting holes. , the mounting hole is connected with a rotating shaft 1, and a rotating motor 7 is also fixed on the frame. The output shaft of the rotating motor 7 is connected with a driving gear, and the left end of the rotating shaft 1 is provided with a driven gear meshing with the driving gear. There is an air intake slot, the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com