Tobacco leaf homogenizing method

A processing method and homogenization technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as uneven distribution of tobacco leaf quality, small batches, and failure to meet cigarette formula requirements, so as to achieve homogenization requirements and improve quality , the effect of reducing the coefficient of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

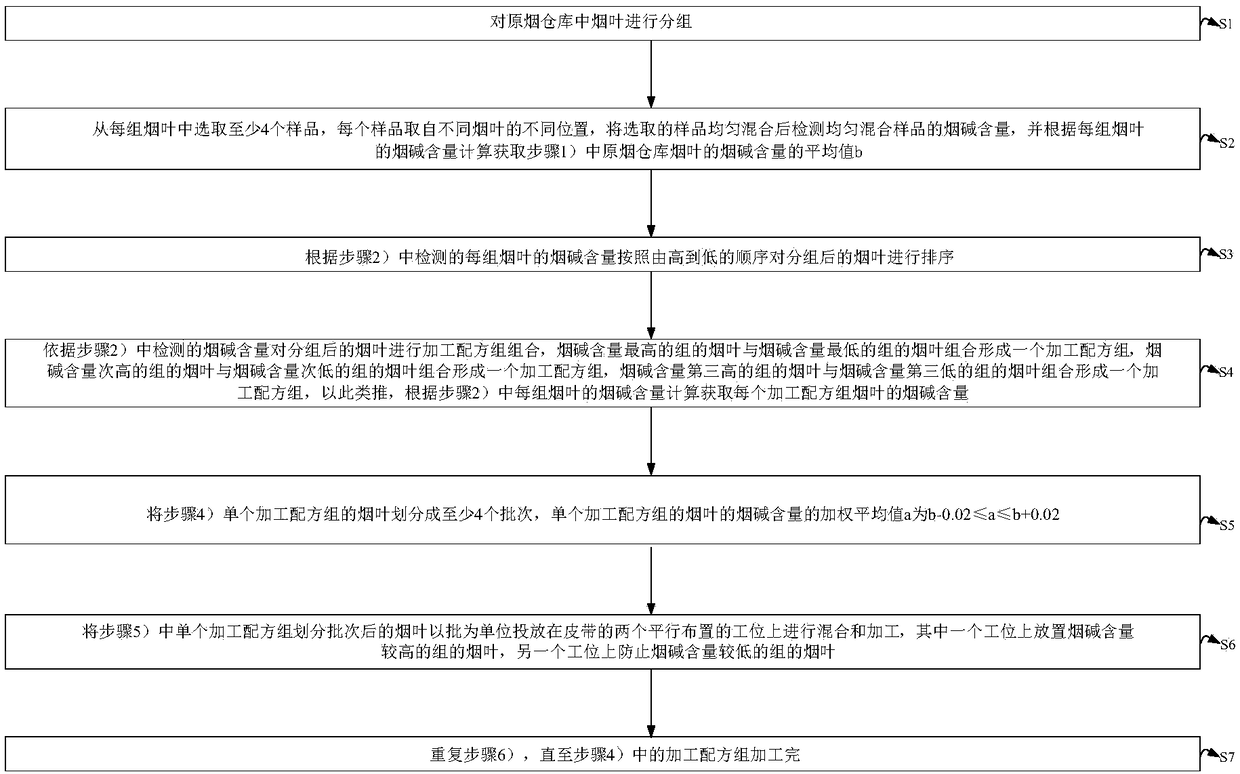

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: Utilize the method processing tobacco leaf of this scheme

[0054] 1. Number of processing grades: C4F (Cloud 87): 10,000 Dan.

[0055] 2. Matching plan design

[0056] (1) Group sampling

[0057] C4F (Cloud 87): 86.4 dan (one rack is 14.4 dan, 6 racks in total) was used as a group of samples for chemical inspection of raw tobacco, and a total of 117 samples were taken.

[0058] (2) Laying platform and feeding design

[0059] A. Design principle of leaf laying table: There are 6 leaf laying belts in Chenzhou, each belt has two stations, and the nicotine level is designed with the two stations of each belt as a unit, and the minimum configuration is the highest, the second The principle of low blending and high quality ensures that the weighted average a of the nicotine content of the tobacco leaves of a single processing combination group is b-0.02≤a≤b+0.02. If the conditions cannot be met, the tobacco leaves of a single processing combination group are...

Embodiment 2

[0065] Embodiment 2: Utilize the method of this scheme to process tobacco leaves.

[0066] 1. Number of processing grades: X2F (K326): 2239 Dan, X2F (Cloud 87): 1116 Dan.

[0067] 2. Matching plan design

[0068] (1) Group sampling

[0069] X2F (K326): 60 Dans (10 Dans for 1 rack, 6 racks in total) were used as a group of samples for raw tobacco chemical inspection, a total of 39 samples were taken; X2F (Cloud 87): 60 Dans (10 Dans for 1 rack of cigarettes) A total of 6 aircraft) were used as a group of samples for the chemical inspection of the original smoke, and a total of 21 samples were taken.

[0070] (2) Laying platform and feeding design

[0071] A. Design principles of leaf laying table:

[0072] There are 6 leaf-laying belts in Chenzhou, and each belt has two stations. The nicotine level matching design is carried out with the two stations of each belt as a unit, and the principle of the lowest matching is the highest, and the second-lowest matching is the highes...

Embodiment 3

[0079] Embodiment 3: Traditional method processing tobacco leaf.

[0080] 1. Number of processing grades

[0081] C4F(K326): 11000 Dan

[0082] 2. Tobacco leaf feeding method: Tobacco leaves enter the leaf laying table from the warehouse and are directly fed.

[0083] 3. Results:

[0084] Results of the coefficient of variation of the chemical composition of the finished tobacco tobacco:

[0085] parameter

[0086] It can be seen from the detection results of the chemical components of the finished cigarette that the coefficient of variation of the nicotine index is 15.104%, and the stability of the nicotine index of the finished cigarette is relatively poor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com